Metallized polyimides film and flexible circuit board using the same

A technology of polyimide film and metal film, which is applied in the direction of circuit substrate materials, improvement of metal adhesion of insulating substrates, metal layered products, etc., can solve problems such as polyimide film peeling, and achieve high industrial value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

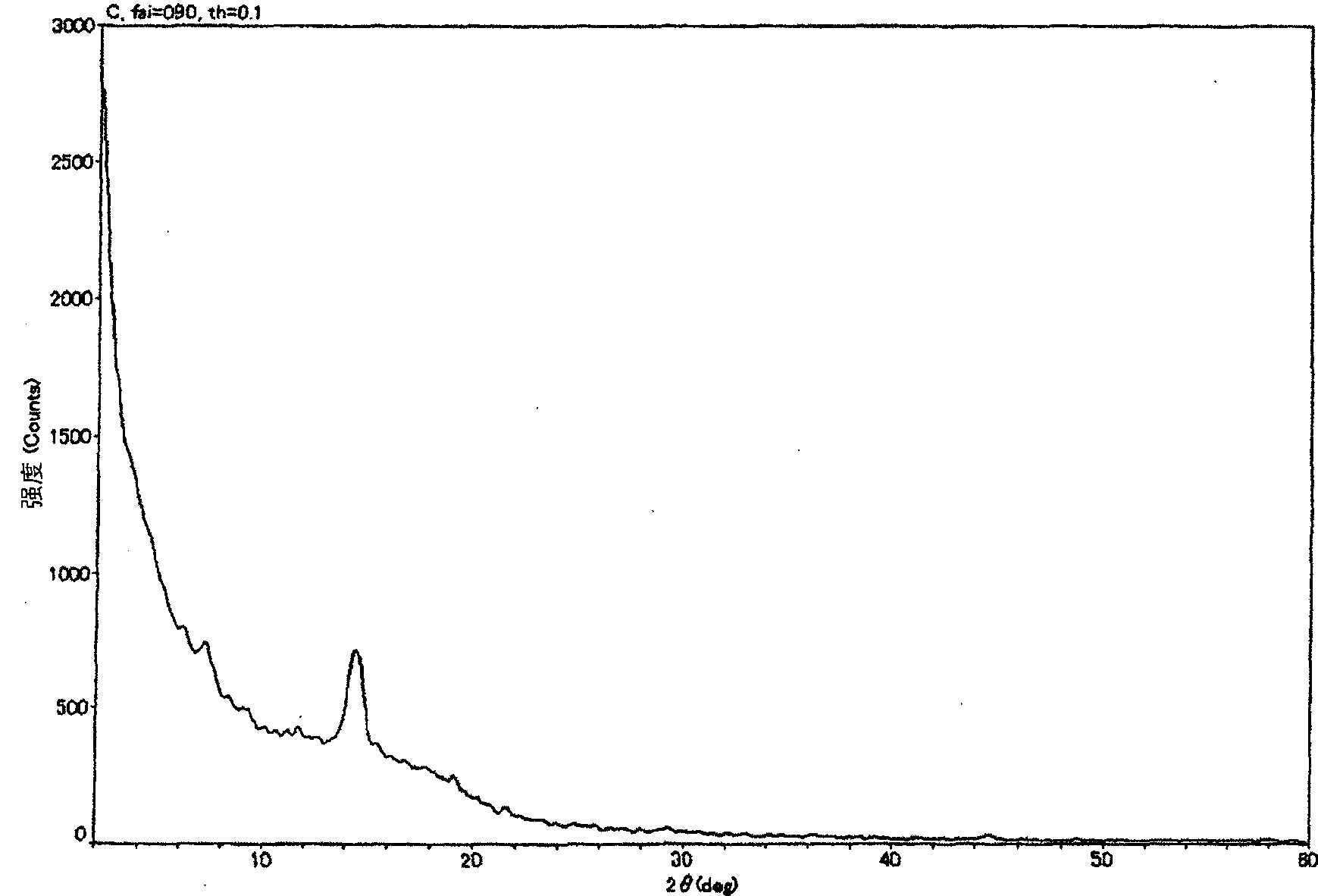

[0102] First, use an oxygen transmission rate of 450cm 3 / (m 2 24 hours 1013hPa), water absorption rate is 1.8%, thermal expansion coefficient is 11ppm / ℃ in TD direction, and if figure 1 As shown in the X-ray diffraction results of the film shown, only a peak with a full width at half maximum of 1.0° was found at 2θ=14°, and a long polyimide film with a thickness of 35 μm mainly composed of biphenyltetracarboxylic acid (manufactured by Kaneka Co., Ltd. 35FP), using a sputtering device consisting of an uncoiler, a sputtering device, and a winding machine, on one side of the polyimide film, an average thickness of The chromium-nickel alloy layer of 20 mass % Cr is used as the metal film. Then, likewise, an average thickness of copper film.

[0103] Next, a copper layer having a thickness of 8 μm was formed on the copper film by electrolytic copper plating to obtain a metallized polyimide film. The electrolytic plating bath used was a copper sulfate plating bath with a cop...

Embodiment 2

[0107] A flexible wiring board was produced in the same manner as in Example 1 except that the metallized polyimide film obtained in Example 1 was used, and the wiring pitch was 25 μm, and the rate of poor bonding was obtained in the same manner as in Example 1. It can be seen that the bonding ratio of the inner lead and the polyimide film is 0.005%, and there is sufficient dimensional reliability even if a fine pitch is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com