Recovery treatment process of mercury-containing waste hydrochloric acid

A technology for recycling and processing waste hydrochloric acid, which is applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems that affect the survival and development of enterprises, high processing costs, and poor processing effects, and achieve good economic benefits and avoid pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

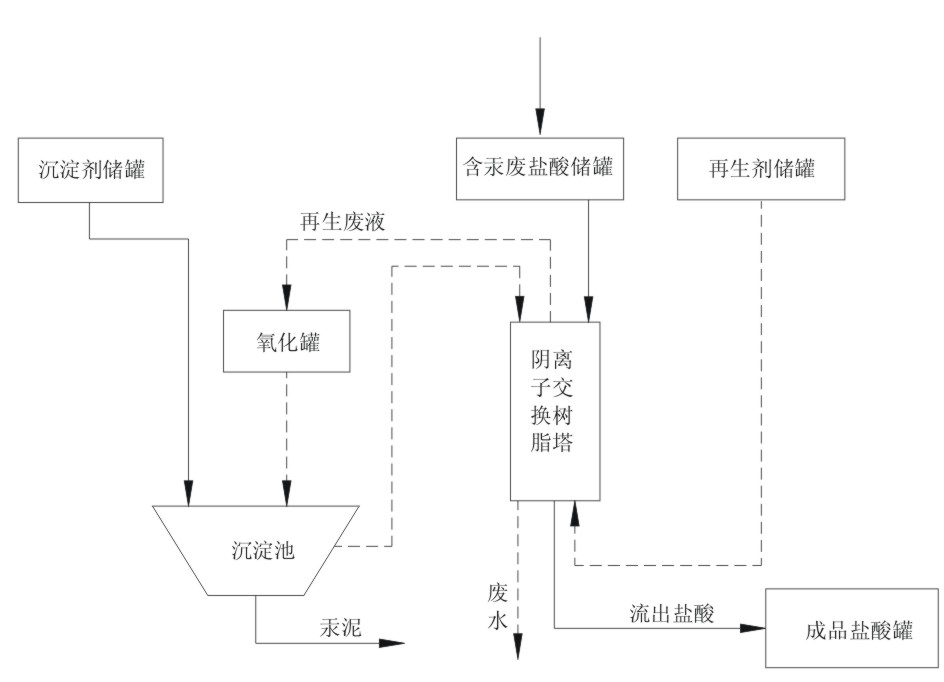

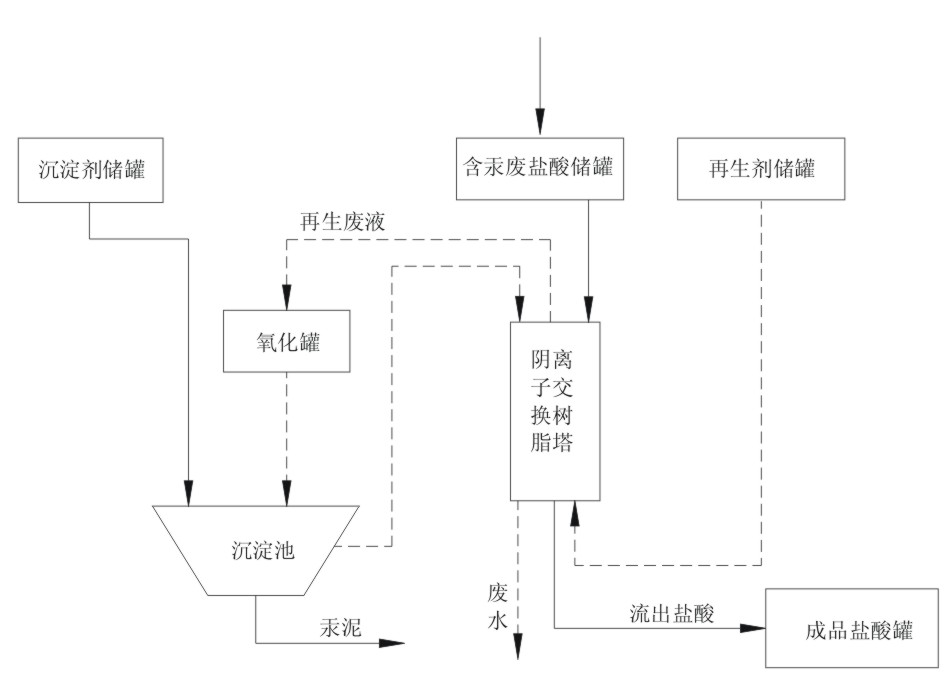

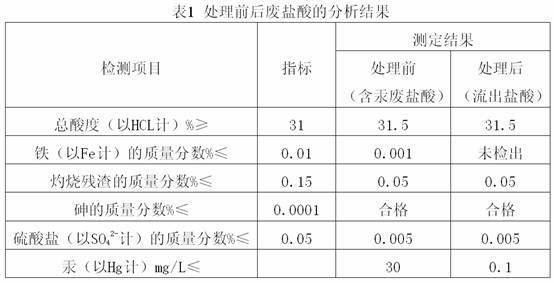

[0021] The recovery and treatment process of mercury-containing waste hydrochloric acid, such as figure 1 As shown, the steps include:

[0022] 1) Pass the waste hydrochloric acid with a mercury content of 30mg / L into a strong basic anion exchange resin tower (filled with British Purite A600MB strong basic anion exchange resin) for ion exchange, and control the flow rate of mercury-containing waste hydrochloric acid to 10L / min Collect and flow out hydrochloric acid in the finished product hydrochloric acid tank, and the mercury content of sampling analysis flowing out hydrochloric acid is 0.05mg / l.

[0023] 2) When the mercury content of the effluent hydrochloric acid reaches more than 0.1mg / L, regenerate the anion exchange resin: feed the regenerant (10wt% sodium sulfite aqueous solution) from the bottom of the resin tower, and control the flow rate of the regenerant at 5L / min. Regeneration treatment for 30 minutes; collect the regeneration waste liquid flowing out from ...

Embodiment 2

[0025] The recovery and treatment process of mercury-containing waste hydrochloric acid, such as figure 1 As shown, the steps include:

[0026] 1) Pass the waste hydrochloric acid with a mercury content of 20mg / L into a strong basic anion exchange resin tower (filled with British Purite A600MB strong basic anion exchange resin) for ion exchange, and control the flow rate of the mercury-containing waste hydrochloric acid to 50 L / min; collect the effluent hydrochloric acid into the finished product hydrochloric acid tank, take a sample and analyze the mercury content of the effluent hydrochloric acid to be 0.08mg / l.

[0027] 2) When the mercury content of the effluent hydrochloric acid reaches above 0.1mg / L, regenerate the anion exchange resin: feed the regenerant (10wt% sodium sulfite aqueous solution) from the bottom of the resin tower, and control the flow rate of the regenerant at 10 L / min , regenerate for 40 minutes; collect the regenerated waste liquid flowing out fr...

Embodiment 3

[0029] The recovery and treatment process of mercury-containing waste hydrochloric acid, such as figure 1 As shown, the steps include:

[0030] 1) Pass the waste hydrochloric acid with a mercury content of 26 mg / L into a strong basic anion exchange resin tower (filled with British Purite A600MB strong basic anion exchange resin) for ion exchange, and control the flow rate of the mercury-containing waste hydrochloric acid to 100 L / min; collect the effluent hydrochloric acid into the finished product hydrochloric acid tank, take a sample and analyze the mercury content of the effluent hydrochloric acid to be 0.02mg / l.

[0031] 2) When the mercury content of the effluent hydrochloric acid reaches above 0.1mg / L, regenerate the anion exchange resin: feed the regenerant (10wt% potassium sulfite aqueous solution) from the bottom of the resin tower, and control the flow rate of the regenerant at 20 L / min , regeneration treatment for 60 minutes; collect the regeneration waste liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com