Giant dielectric-nonlinear low-voltage difunctional varistor ceramic material and preparation method thereof

A ceramic material and non-linear technology, which is applied in the field of giant dielectric varistors and non-linear varistor materials, can solve the problems of varistor characteristics that are not recorded, and achieve the effects of short cycle, simple process operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

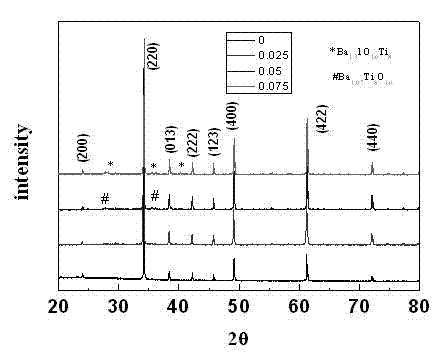

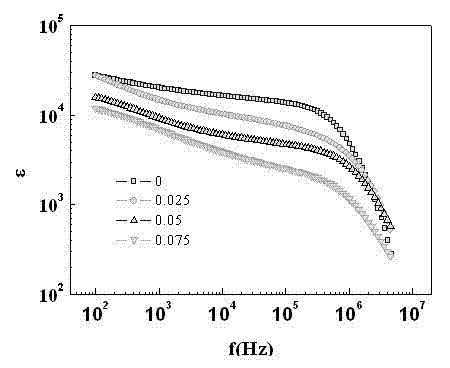

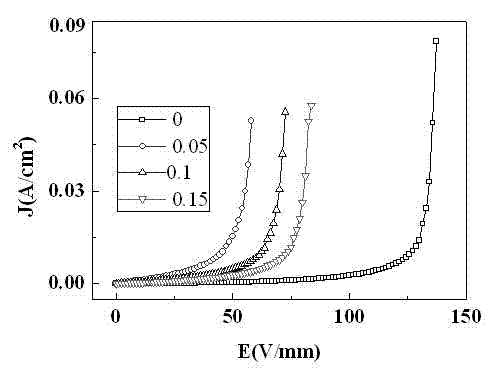

[0019] Preparation of Bi by sol-gel method using citric acid as complexing agent 0.5-x Na 0.5-x Ba 2x Cu 3 Ti 4 O 12 (x=0) Ceramic. First, weigh 0.08mol of citric acid into a 100mL beaker 1, add 35mL of deionized water, dissolve under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of butyl titanate into a 100mL beaker 2, then Transfer the citric acid solution in 1 beaker to the titanium solution in 2 beakers; dissolve the titanium solution under constant stirring, then ultrasonically disperse for 30 min, and then add 5 mL of ethylene glycol to form a transparent solution. The molar ratio of butyl titanate and citric acid aqueous solution is 1:2. In the second step, 0.05mol of citric acid was weighed into a 500mL beaker, 20mL of deionized water was added, and dissolved under ultrasonic dispersion to form a transparent solution; then 0.03mol of copper nitrate, 0.005mol of sodium nitrate, 0.005 mol of bismuth nitrate was added to the above soluti...

Embodiment 2

[0022] Preparation of Bi by sol-gel method using citric acid as complexing agent 0.5-x Na 0.5-x Ba 2x Cu 3 Ti 4 O 12 (x=0.025) Ceramic. First, weigh 0.08mol of citric acid into a 100mL beaker 1, add 35mL of deionized water, dissolve under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of butyl titanate into a 100mL beaker 2, then Transfer the citric acid solution in 1 beaker to the titanium solution in 2 beakers; dissolve the titanium solution under constant stirring, then ultrasonically disperse for 30 min, and then add 5 mL of ethylene glycol to form a transparent solution. The molar ratio of butyl titanate and citric acid aqueous solution is 1:2. In the second step, 0.05mol of citric acid was weighed into a 500mL beaker, 20mL of deionized water was added, and dissolved under ultrasonic dispersion to form a transparent solution; then 0.03mol of copper nitrate, 0.00475mol of sodium nitrate, 0.00475 mol of bismuth nitrate and 0.0005 mol of bar...

Embodiment 3

[0025] Preparation of Bi by sol-gel method using citric acid as complexing agent 0.5-x Na 0.5-x Ba 2x Cu 3 Ti 4 O 12 (x=0.005) Ceramic. First, weigh 0.08mol of citric acid into a 100mL beaker 1, add 35mL of deionized water, dissolve under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of butyl titanate into a 100mL beaker 2, then Transfer the citric acid solution in 1 beaker to the titanium solution in 2 beakers; dissolve the titanium solution under constant stirring, then ultrasonically disperse for 30 min, and then add 5 mL of ethylene glycol to form a transparent solution. The molar ratio of butyl titanate and citric acid aqueous solution is 1:2. In the second step, 0.05mol of citric acid was weighed into a 500mL beaker, 20mL of deionized water was added, and dissolved under ultrasonic dispersion to form a transparent solution; then 0.03mol of copper nitrate, 0.0045mol of sodium nitrate, 0.0045 mol of bismuth nitrate and 0.001 mol of barium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com