Method for preparing porous silicon nitride wave transmitting ceramic with low dielectric constant and high strength

A silicon nitride wave-transparent and low-dielectric constant technology, which is applied in the preparation of high-strength porous silicon nitride wave-transparent ceramics and low-dielectric constant fields, can solve the problem of difficult control of pore distribution uniformity, large pore size, and complex methods etc. to achieve the effect of low cost, high porosity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

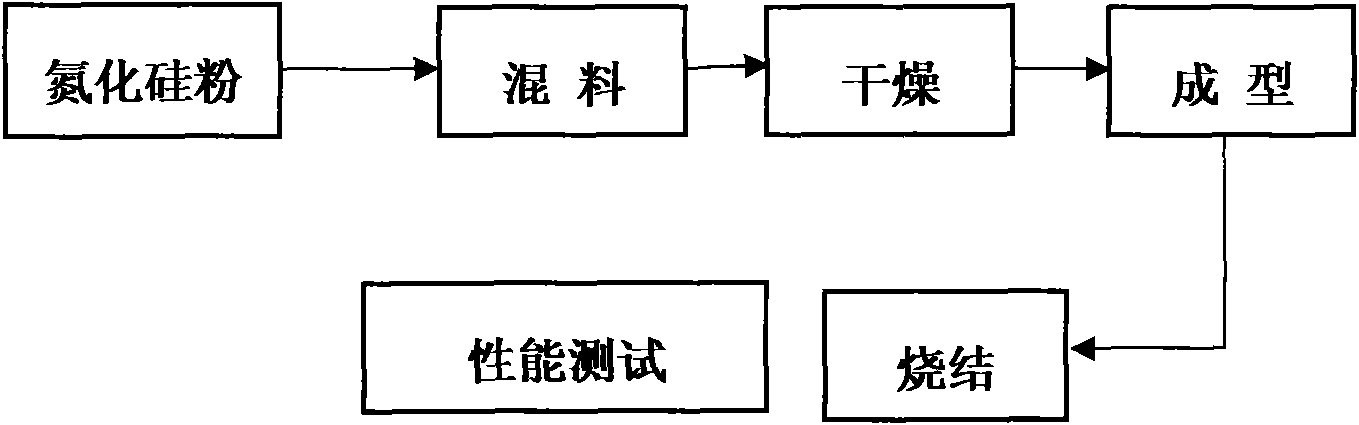

Method used

Image

Examples

Embodiment 1

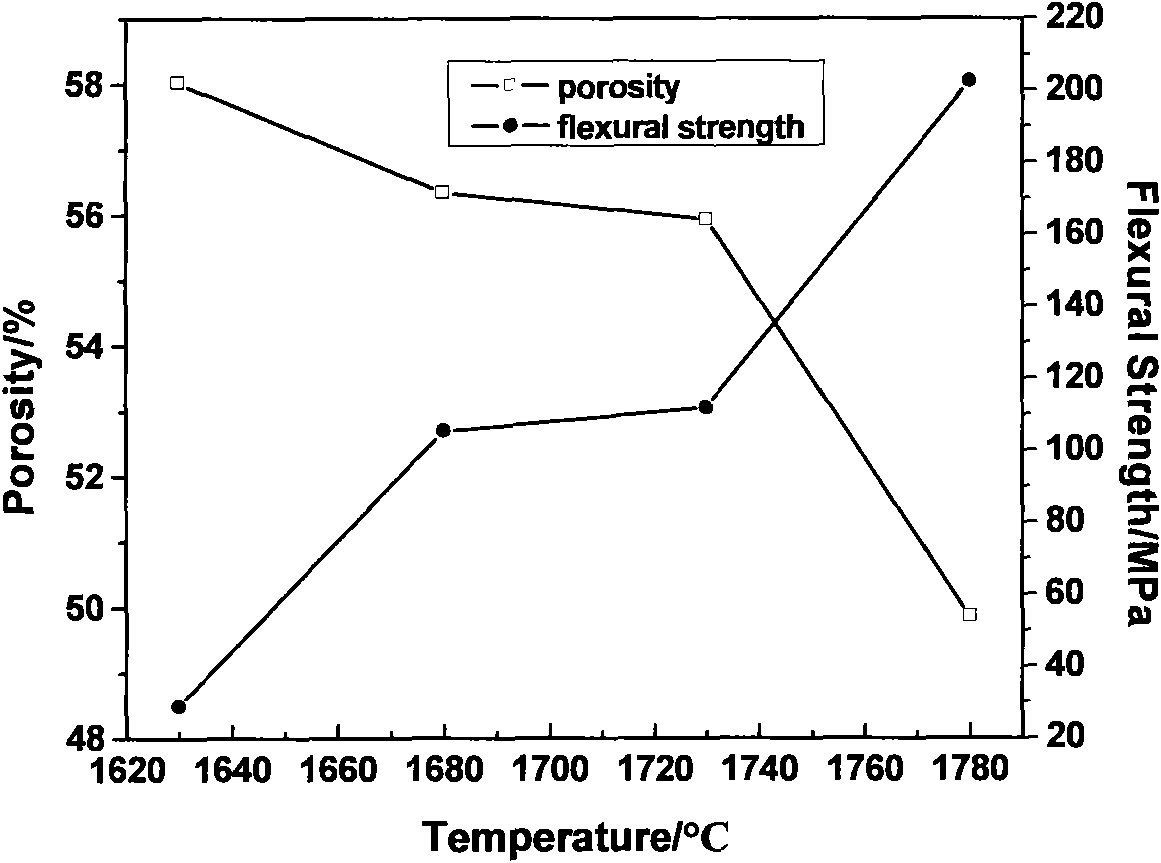

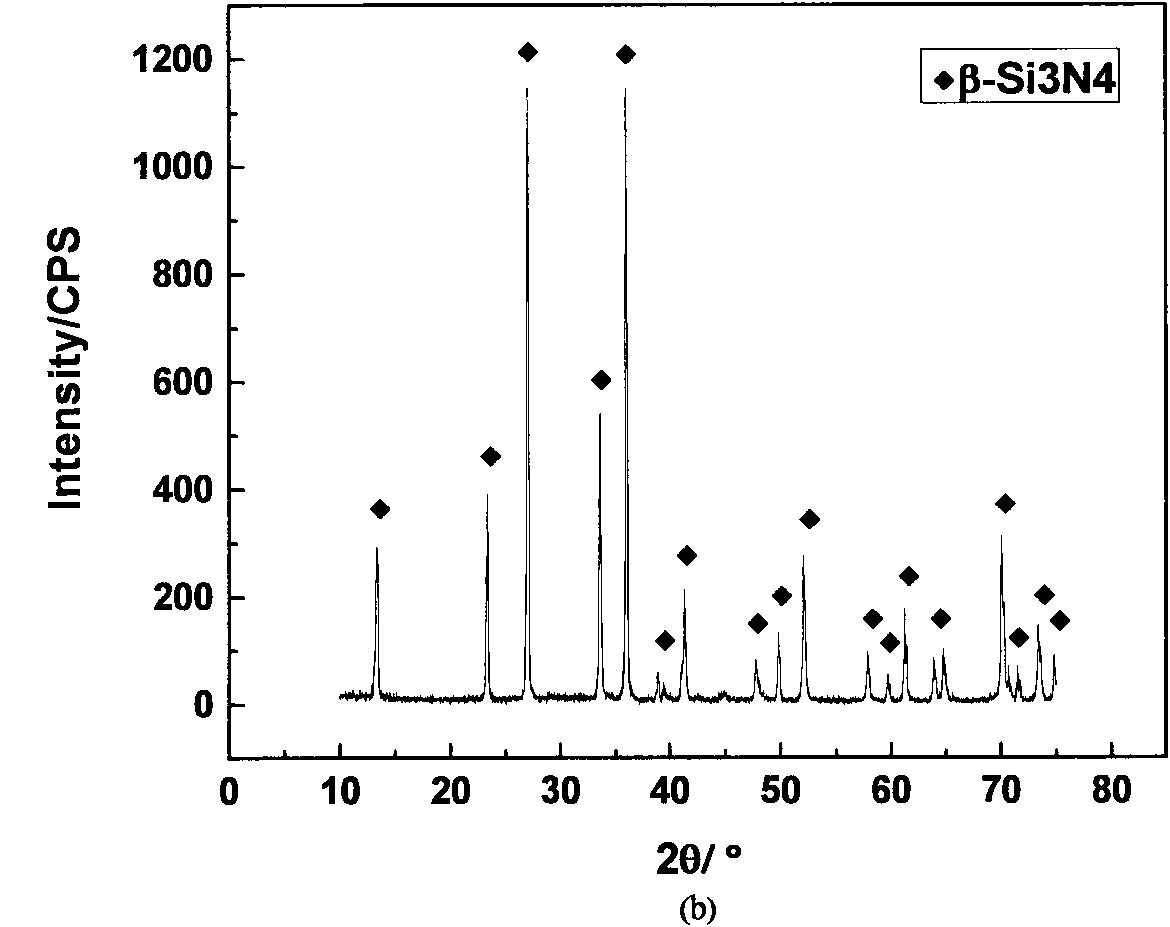

[0024] Weighing 90 grams of silicon nitride powder, the particle size of the silicon nitride is 0.3-3 microns, the alpha phase content is greater than 93%, and the purity is greater than 99.9%. Add 5 grams of aluminum oxide and 5 grams of yttrium oxide, wherein the average particle size of aluminum oxide is 0.3 microns, the purity is greater than 99.8%, and the particle size of yttrium oxide is 1-10 microns, and the purity is greater than 99%. The three are mixed, with the analysis of pure alcohol as the medium, adding 30% of the total mass of the powder, using agate balls as grinding balls, powder: agate balls=1: 2 (mass ratio), and mixing for 12 hours to make the material pulp, dried to make dry powder, and sieved. Then put the mixed powder into a mold with a diameter of 60mm, pressurize and shape at 50MPa, and sinter the formed green body at 1600°C under a vacuum / nitrogen protective atmosphere. The specific sintering process is carried out in stages: below 800°C, the heati...

Embodiment 2

[0028] Weighing 85 grams of silicon nitride powder, the particle size of the silicon nitride is 0.3-3 microns, the alpha phase content is greater than 93%, and the purity is greater than 99.9%. Add 10 grams of yttrium oxide and 5 grams of silicon oxide, wherein the particle size of the yttrium oxide is 1-10 microns, the purity is greater than 99%, the purity of the silicon oxide is more than 99%, and the average particle size is less than 100 nanometers. Mix the three, use pure alcohol as the medium, add 60% of the total mass of the powder, use agate balls as the grinding balls, powder: agate balls=1:2 (mass ratio), and mix the materials for 24 hours to make the material pulp, dried to make dry powder, and sieved. Then put the mixed powder into a mold with a diameter of 60mm, pressurize and shape at 70MPa, and sinter the formed body at 1700°C under a vacuum / nitrogen protective atmosphere. The specific sintering process is carried out in stages: below 800°C, the heating rate i...

Embodiment 3

[0032] Weighing 85 grams of silicon nitride powder, the particle size of the silicon nitride is 0.3-3 microns, the alpha phase content is greater than 93%, and the purity is greater than 99.9%. Add 10 grams of yttrium oxide and 5 grams of aluminum oxide, wherein the particle size of yttrium oxide is 1-10 microns, the purity is greater than 99%, the purity of silicon oxide is >99%, and the average particle size is <100 nanometers. The three are mixed, with the analysis of pure alcohol as the medium, add by 40% of the total mass of the material powder, use the agate ball as the grinding ball, the material powder: agate ball=1: 2 (mass ratio), and mix the materials for 20 hours to make the material pulp, dried to make dry powder, and sieved. Then put the mixed powder into a mold with a diameter of 60mm, pressurize and shape at 100MPa, and sinter the formed green body at 1800°C under a vacuum / nitrogen protective atmosphere. The specific sintering process is carried out in stages:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com