Low-yield strength anti-ageing continuous annealing cold-roll steel sheet and production method thereof

A low-yield strength, cold-rolled steel plate technology, applied in the field of steel rolling, can solve the problems of poor process control stability, small diameter of furnace rolls in the over-aging section, poor mechanical properties, etc., and achieve the effect of expanding product use and expanding the range of product thickness specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

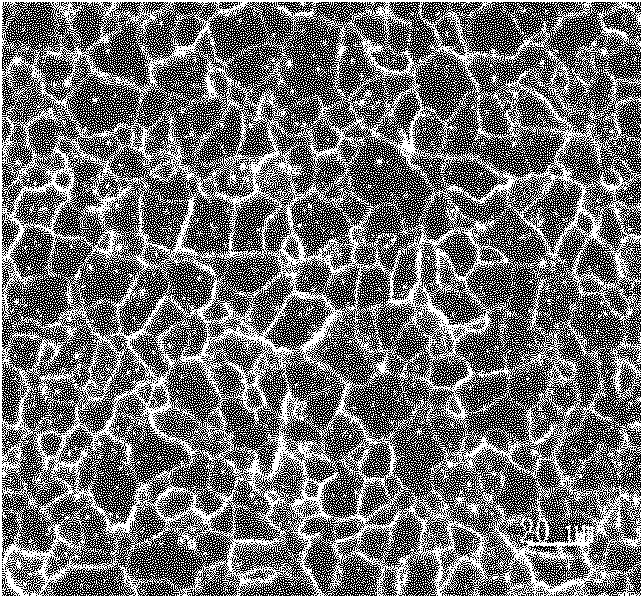

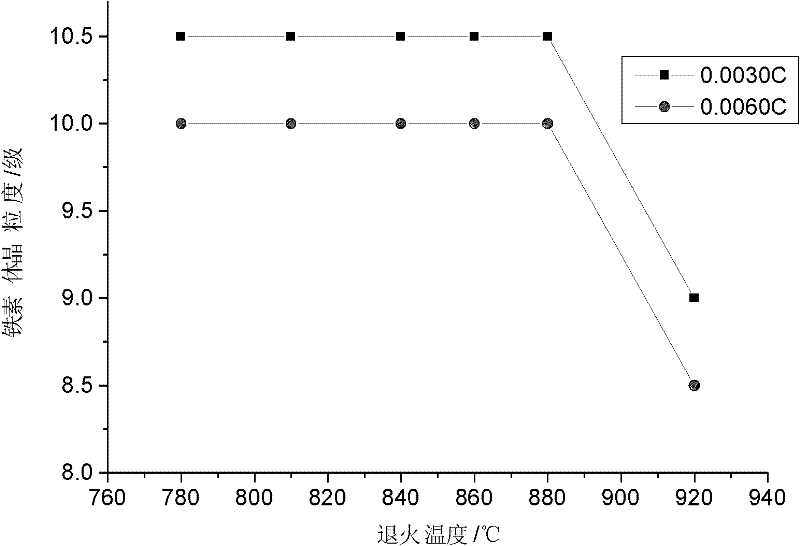

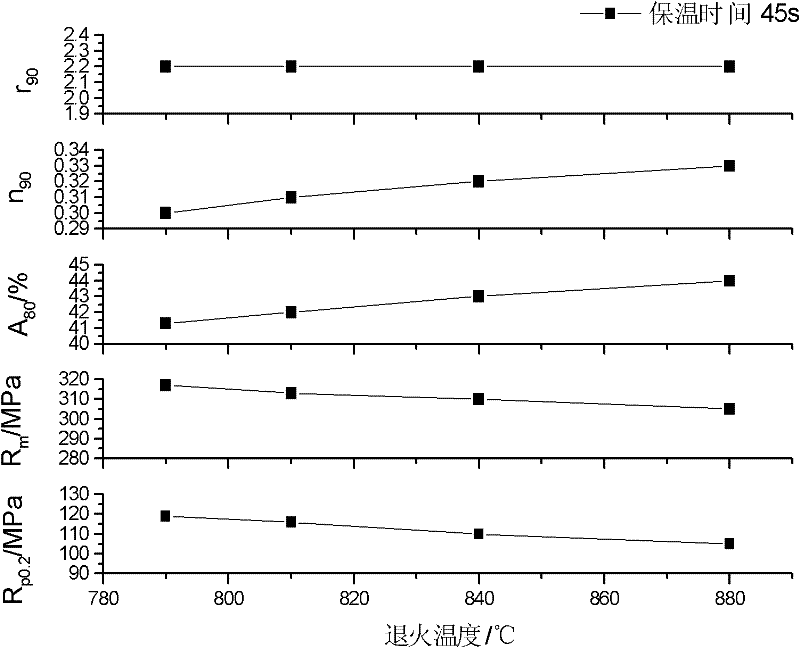

[0045] Smelted in a converter and subjected to vacuum treatment to obtain molten steel for producing low-yield-strength aging-resistant cold-rolled steel sheets according to the present invention, its chemical composition (by weight percentage) contains C: 0.0060, Si: 0.010, Mn: 0.18, P: 0.010, S: 0.010 , Ti: 0.073, Als: 0.045, and the balance is Fe and unavoidable impurities.

[0046] After continuous casting, the slab is heated and rolled at 1200°C to form a strip steel with a thickness of 2.50mm. The final rolling temperature of hot rolling is 880°C. After rolling, it is rapidly cooled to 780°C and then air-cooled for 10s to ensure complete transformation of ferrite and precipitated phases. Precipitate, then enter the coiler to coil into coils, pickle the strip steel with hydrochloric acid (170-190g / L) after cooling, and roll it into a cold-rolled sheet of 0.5mm with a reduction rate of 80.0% on the cold tandem mill. The rolled steel strip is passed through continuous annea...

Embodiment 2

[0048] Smelted in a converter and subjected to vacuum treatment to obtain molten steel for producing low-yield-strength aging-resistant cold-rolled steel sheets according to the present invention, its chemical composition (by weight percentage) contains C: 0.0050, Si: 0.020, Mn: 0.20, P: 0.012, S: 0.013 , Ti: 0.070, Als: 0.040, and the balance is Fe and unavoidable impurities.

[0049] After continuous casting, the slab is heated and rolled at 1200°C to form a strip steel with a thickness of 2.75mm. The final rolling temperature of hot rolling is 890°C. After rolling, it is rapidly cooled to 750°C and then air-cooled for 10s to ensure complete transformation of ferrite and phase precipitation. Precipitate, and then enter the coiler to coil into coils, pickle the strip steel with hydrochloric acid after cooling, and roll it into a cold-rolled plate of 0.6mm with a reduction rate of 78.2% on the cold tandem rolling mill. An annealing / hot-dip galvanizing dual-purpose unit is used...

Embodiment 3

[0051] Smelted in a converter and subjected to vacuum treatment to obtain molten steel for producing low-yield-strength aging-resistant cold-rolled steel sheets according to the present invention, its chemical composition (by weight percentage) contains C: 0.0045, Si: 0.010, Mn: 0.18, P: 0.010, S: 0.010 , Ti: 0.068, Als: 0.050, and the balance is Fe and unavoidable impurities.

[0052] After continuous casting, the slab is heated and rolled at 1200°C to form a strip steel with a thickness of 2.75mm. The final rolling temperature of hot rolling is 890°C. After rolling, it is rapidly cooled to 750°C and then air-cooled for 10s to ensure complete transformation of ferrite and phase precipitation. Precipitate, then enter the coiler to coil into coils, pickle the strip steel with hydrochloric acid after cooling, and roll it into a cold-rolled plate of 0.7mm with a reduction rate of 74.5% on the cold tandem rolling mill. An annealing / hot-dip galvanizing dual-purpose unit is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com