Semi high speed steel cold-rolling intermediate roll and manufacturing method thereof

A manufacturing method, semi-high-speed steel technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of uneven load distribution, high fatigue cycle, long machine cycle, etc., to achieve excellent contact fatigue resistance, Good thermal shock resistance, good resistance to mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The manufacturing method of the cold-rolled intermediate roll of the present embodiment comprises the following steps:

[0019] ① Refining steel to make the chemical composition and content of the steel meet the required range, and using conventional production processes to produce cold-rolled billets. The specific steps are: when making steel, use electric arc furnace and LF / VD refining furnace to smelt molten steel, and mold the steel into electrode rods, then anneal the electrode rods, and then use electroslag remelting to make the cost. Example composition of electroslag ingot.

[0020] After final analysis, the chemical composition and percentage content of the above-mentioned electroslag ingots are shown in the following table:

[0021] C

Si

mn

Cr

Mo

V

Ni

P

S

0.67

1.05

0.36

5.29

1.21

0.29

0.16

0.017

0.003

[0022] The rest is Fe and unavoidable impu...

Embodiment 2~ Embodiment 8

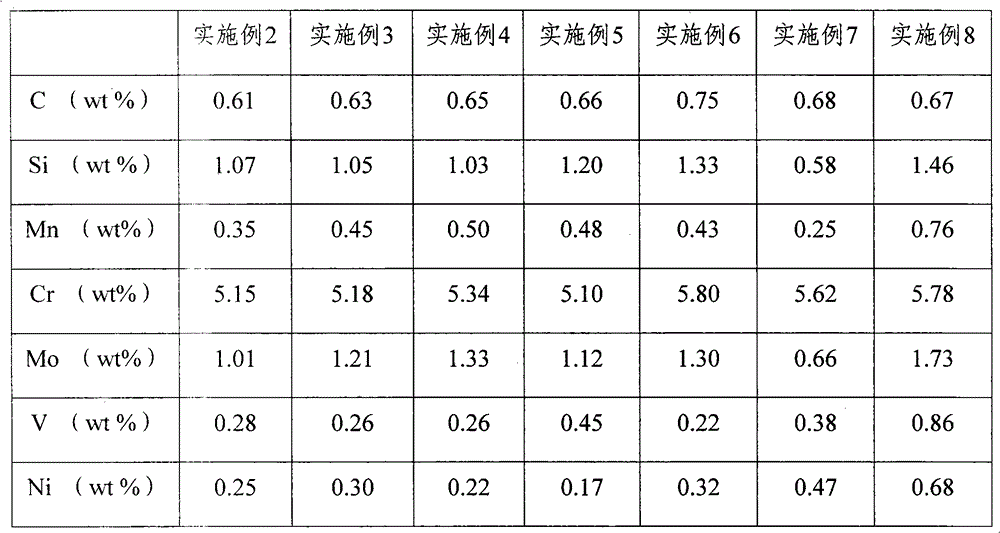

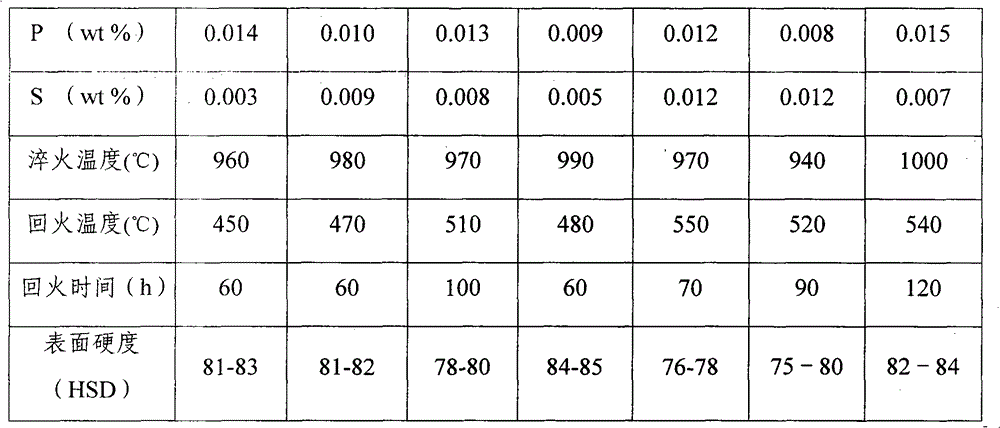

[0028] The manufacturing method of each embodiment is identical with embodiment 1, and the chemical composition and percentage composition and the surface hardness of finished product in process condition, cold roll material are shown in the table below:

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com