Micro-fluid control liquid drop generation system based on liquid drop sequence assembly technology and use method

An assembly technology and droplet generation technology, applied in the field of microfluidic droplet generation system, can solve the problems of expensive processing equipment, increase the difficulty of microfluidic manipulation, complex micromachining technology, etc., and achieve the effect of simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

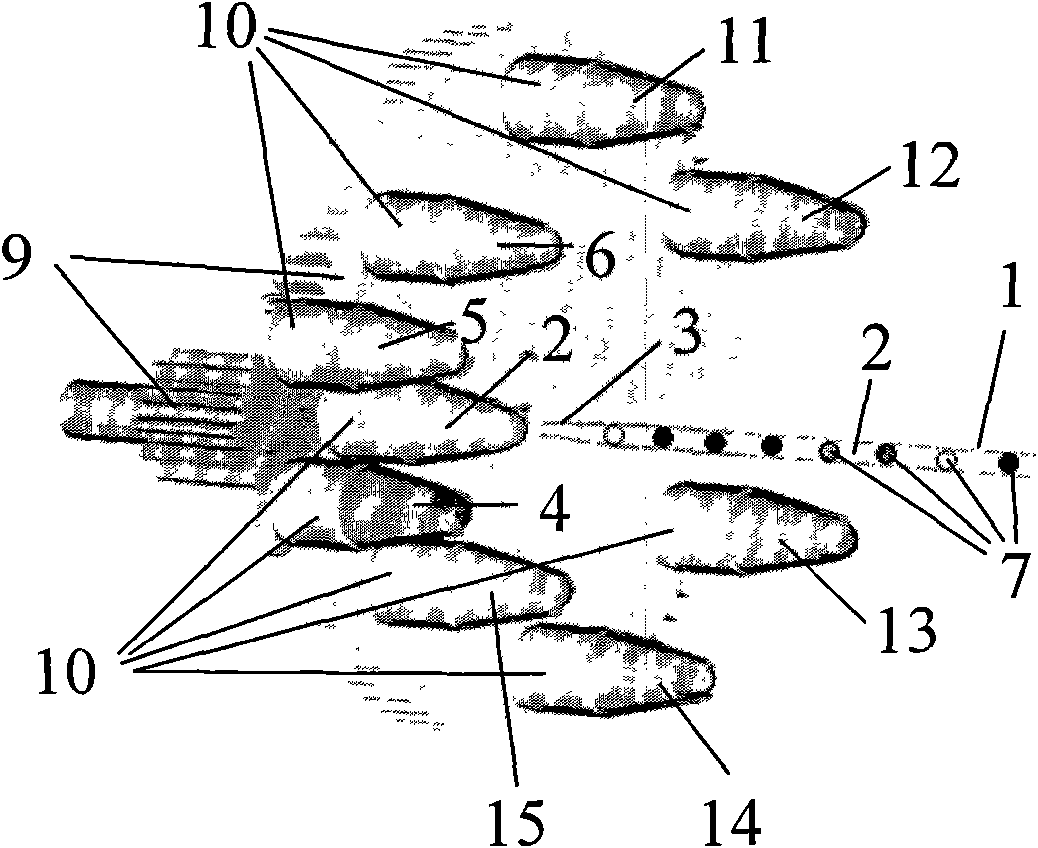

[0046] figure 2It is a schematic diagram of the device of the automatic droplet generation system based on the notched tube array in Example 1. The system consists of three parts: a sample presentation device based on a notched tube array, a quartz capillary, and a microsyringe pump. The sample providing device based on the notched tube array is composed of a gear set 9 composed of two gears, one big and one small, and the small gear is controlled by a stepping motor to drive the big gear to rotate. On the large gear, 6 notched tubes 10 are equidistantly arranged; on the small gear, 3 notched tubes 10 are fixed according to an isosceles triangle. Liquid A4, liquid B5, liquid C6, liquid D11, liquid E12, liquid F13, liquid G14, liquid H15 and oil 2 required for generating droplet arrays are contained in the notched tubes respectively. When generating liquid droplets, the gear set 9 is rotated so that the required liquid in the notched tube 10 contacts the liquid inlet 3 of th...

Embodiment 2

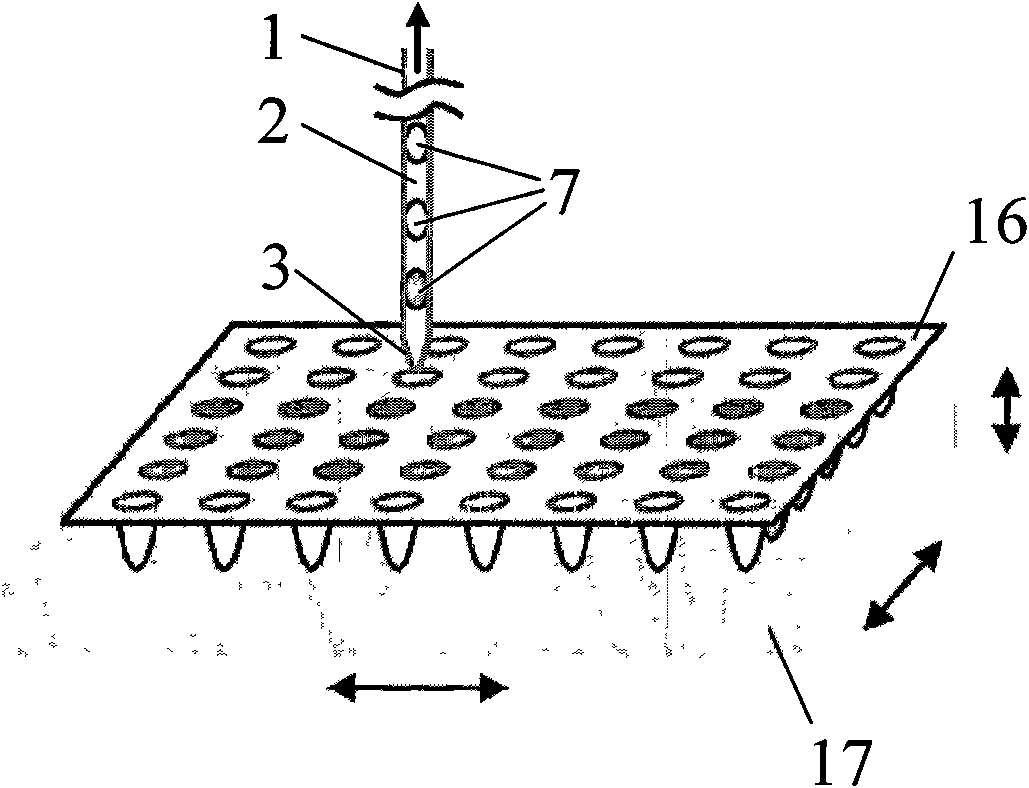

[0048] image 3 It is a schematic diagram of the device of the automatic droplet generation system based on the porous plate in Example 2. The system consists of three parts: a sample presentation device based on a porous plate 16, a quartz capillary, and a micro-injection pump. The sample presentation device based on the porous plate 16 is composed of the porous plate 16 for containing various liquids and a three-dimensional translation stage 17 . When generating liquid droplets, move the three-dimensional translation stage 17, so that the different liquids contained in the porous plate 16 contact the liquid inlet 3 of the capillary 1 in sequence, absorb a certain volume of liquid into the capillary 1, and assemble and generate liquid droplets 7. In the example: the inner diameter of the capillary 1 is 0.5 micron, and the flow rate of the liquid driven by the driving device is 1 picoliter / minute.

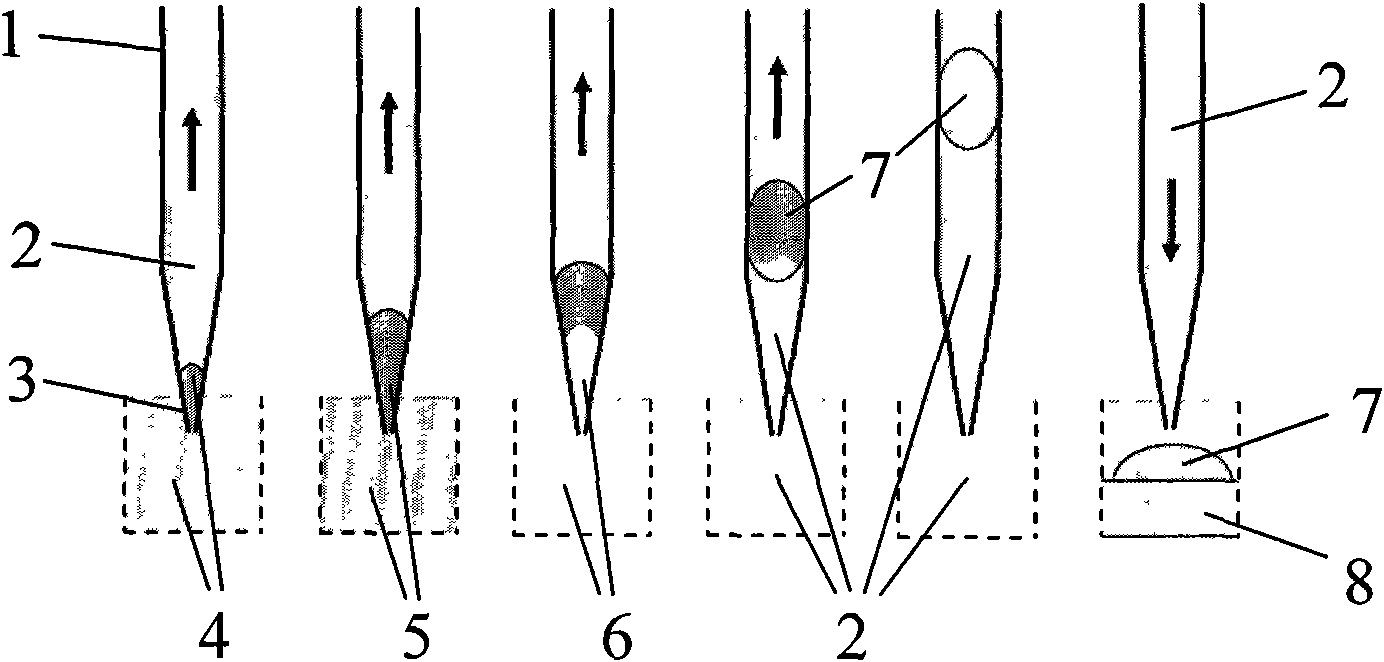

[0049] Figure 4 It is a schematic diagram of the operation of dropping dro...

Embodiment 3

[0052] The oil-immersed droplet array plate 8 is made of glass, and the small pit containing the liquid droplet 7 on the droplet array plate 8 is processed by photolithography and chemical etching. The volume of the small pit is 20 nanoliters, and the capillary 1 The inner diameter is 150 microns, the flow rate of the liquid driven by the driving device is 10 nanoliters / minute, and the rest is the same as in Embodiment 2.

[0053] The volume of the wells can also be 1 nanoliter or 1 microliter, ranging from 1 picoliter to 100 microliters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com