Process for producing sintered ore and sintering machine

A manufacturing method and technology for sintering ore, which are applied in the directions of liquid carbonaceous fuel, lighting and heating equipment, furnace types, etc., can solve the problems of increased exhaust SOx, difficulty in supplying combustible gas, and heat supply limit for sintering raw material layers, etc. Reduce the effect of backfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

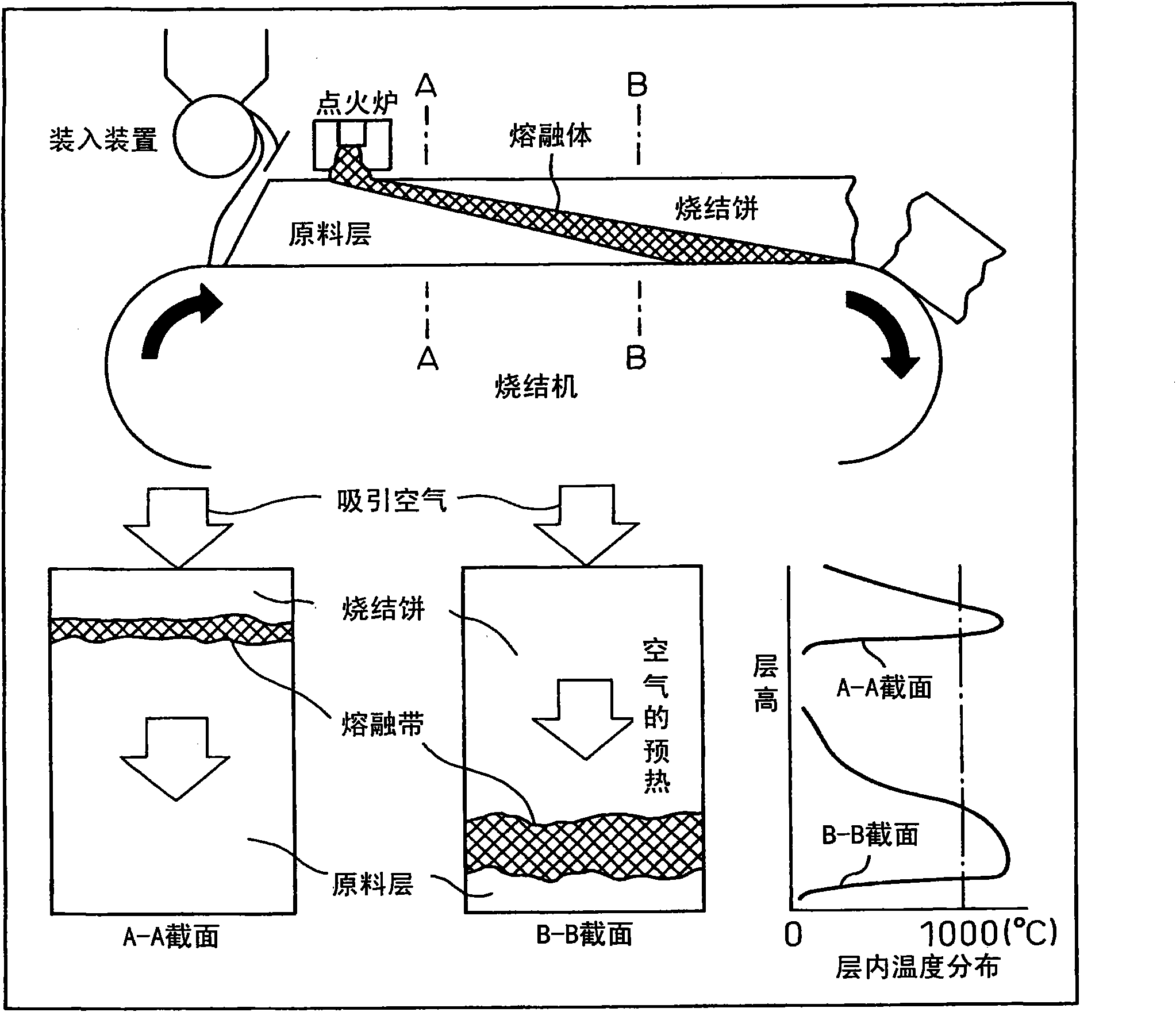

[0134] Using a sintering test device with an inner diameter of 300 mmφ x a height of 600 mm, the blended raw materials shown in Table 1 were loaded, and a sintering test was performed. Within 5 minutes from 3 minutes to 8 minutes after the start of ignition on the surface of the sintered raw material layer, 7 kg of various liquid fuels shown in Table 3 were sprinkled per 1 ton of the blended raw material, and a sintering test was carried out to measure the productivity of the sintered ore, Changes in qualified rate, quality and exhaust oxygen concentration of finished products. A summary of the test results is shown in Table 4. In addition, regarding the heavy oil spreading test shown in Comparative Example 5, the heavy oil remained without burning under the test conditions in which the spreading started 3 minutes after ignition, so the test conditions were changed to 1.5 minutes to 3.0 minutes after ignition. Dispersion takes place within 1.5 minutes.

[0135]

[0136] ...

no. 2 Embodiment

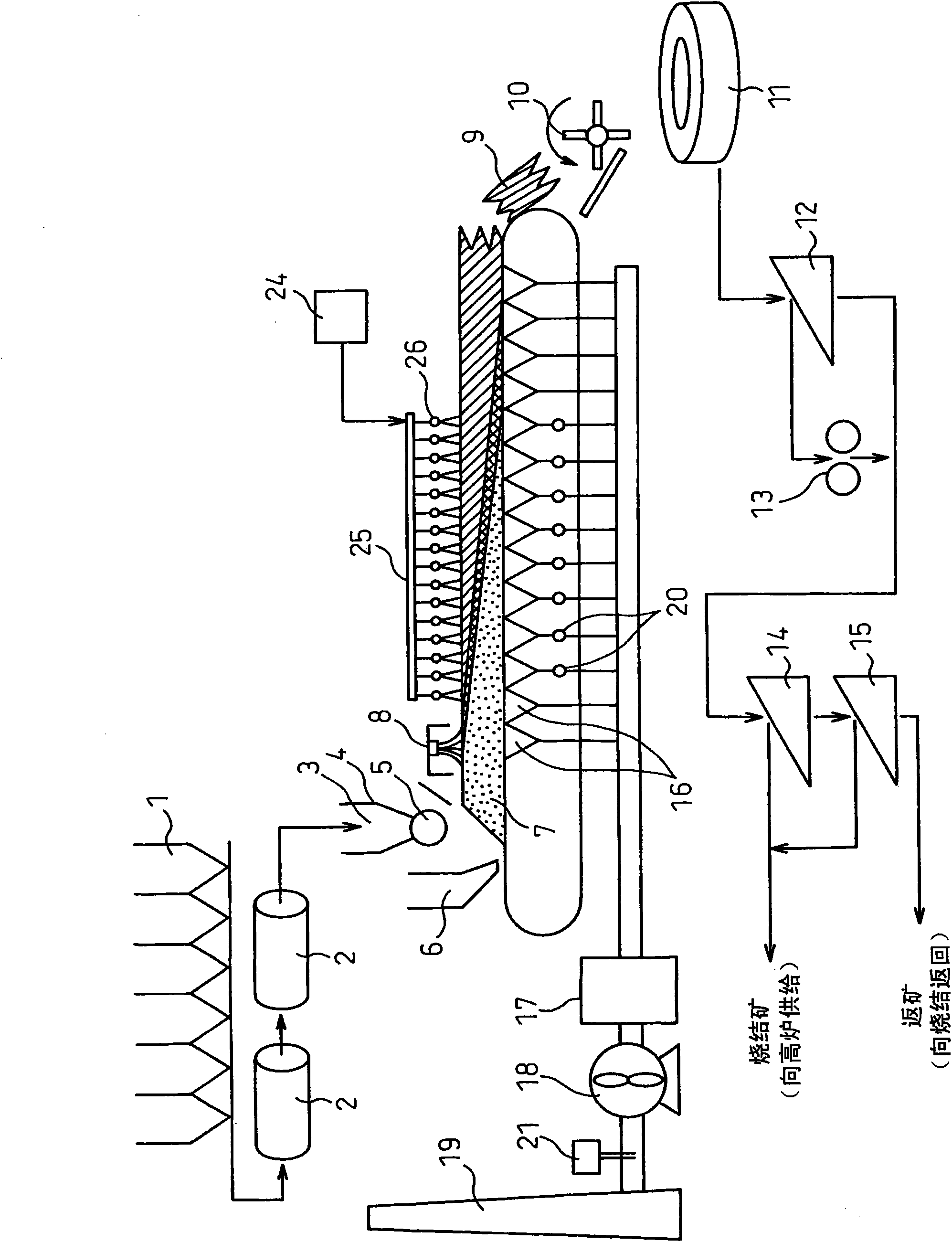

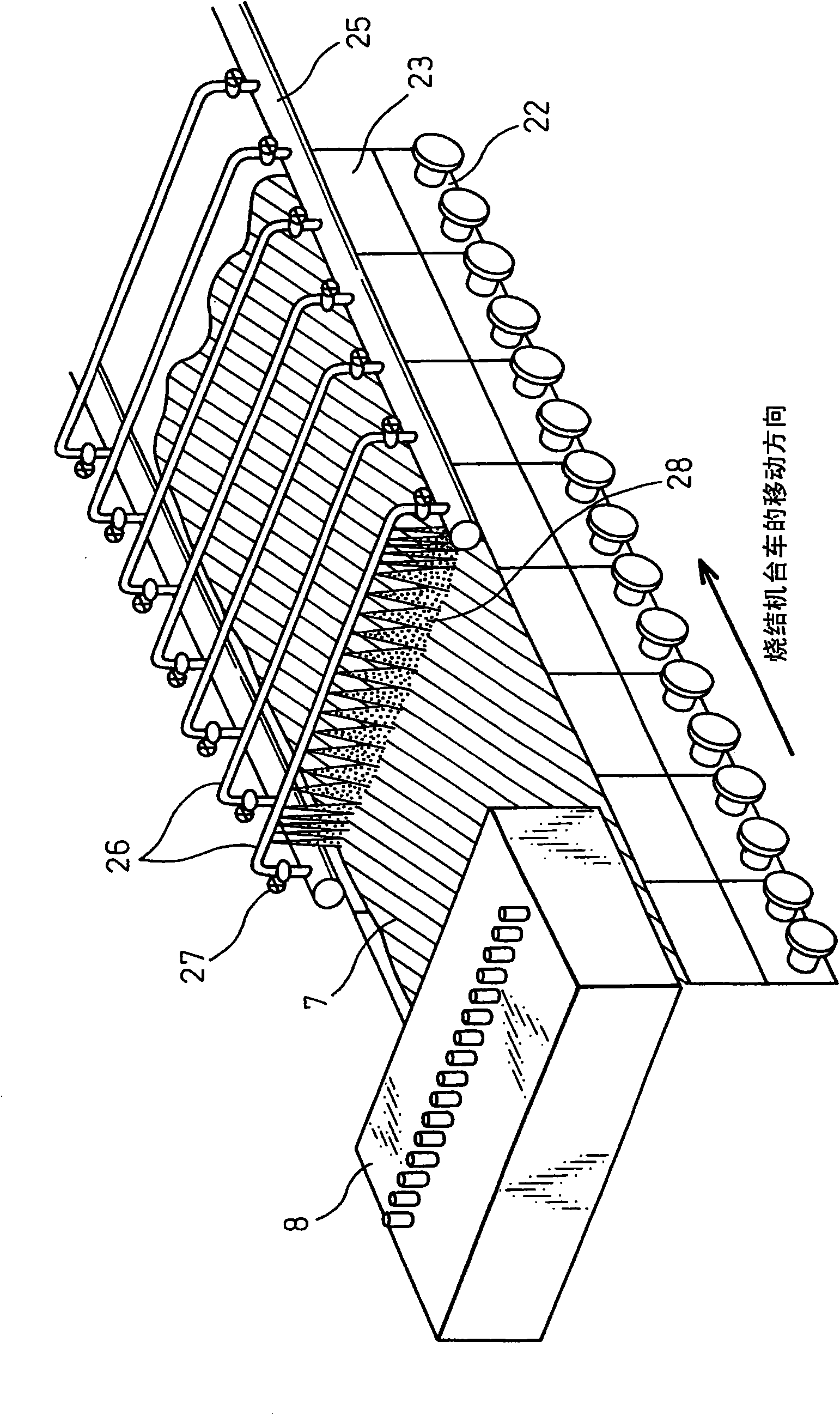

[0143] For a sintering area of 600m 2 , a sintering machine with a trolley width of 5m and a machine length of 120m, set figure 2 With the liquid fuel spray nozzle shown, the liquid fuel spray amount and spray position were changed, and the operation test was carried out. Table 5 shows the composition of raw materials used in this test. In this test, the raw material mix was not changed, and the operation test was carried out under stable conditions in which the layer thickness of the sintering machine was set to 580 mm and the negative pressure was set to 1600 mmAq.

[0144] The test standards for liquid fuel dispersion are shown in Table 6. Using ethanol as the liquid fuel, spraying an amount corresponding to 3.5 kg or 7.0 kg per 1 ton of compounding raw materials was performed to perform a comparison test with an operation in which no liquid fuel was sprayed. The scattered positions are divided into 3 areas: Area A (range of 5-30% of the captain), area B (range of 30-...

no. 3 Embodiment

[0156] Under the same sintering machine, raw material mix, operating conditions, and liquid fuel spraying conditions as in Example 11 in Table 7, the test was performed by adjusting the spraying amount in the width direction of the liquid fuel spraying nozzle. In this test, 50% more liquid fuel was sprayed than the central part to the part in the range of 500 mm from the side walls on both sides of the sintering pallet. However, the total amount of sprayed liquid fuel is the same as in Examples, and corresponds to a total of 7.0 kg per 1 ton of compounded raw materials.

[0157] The survey results of the pass rate distribution of the sintered cake obtained in this test are as follows: Figure 7 shown. Conditions for spreading ethanol uniformly in the width direction ( Figure 7 Under (a)), it was found that the pass rate near the side wall decreased, and under the condition of increasing the amount of dispersion near the side wall ( Figure 7 (b)), a sintered cake having a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com