Defect detection and response

A defect, infrared camera technology, applied in the field of photovoltaic cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

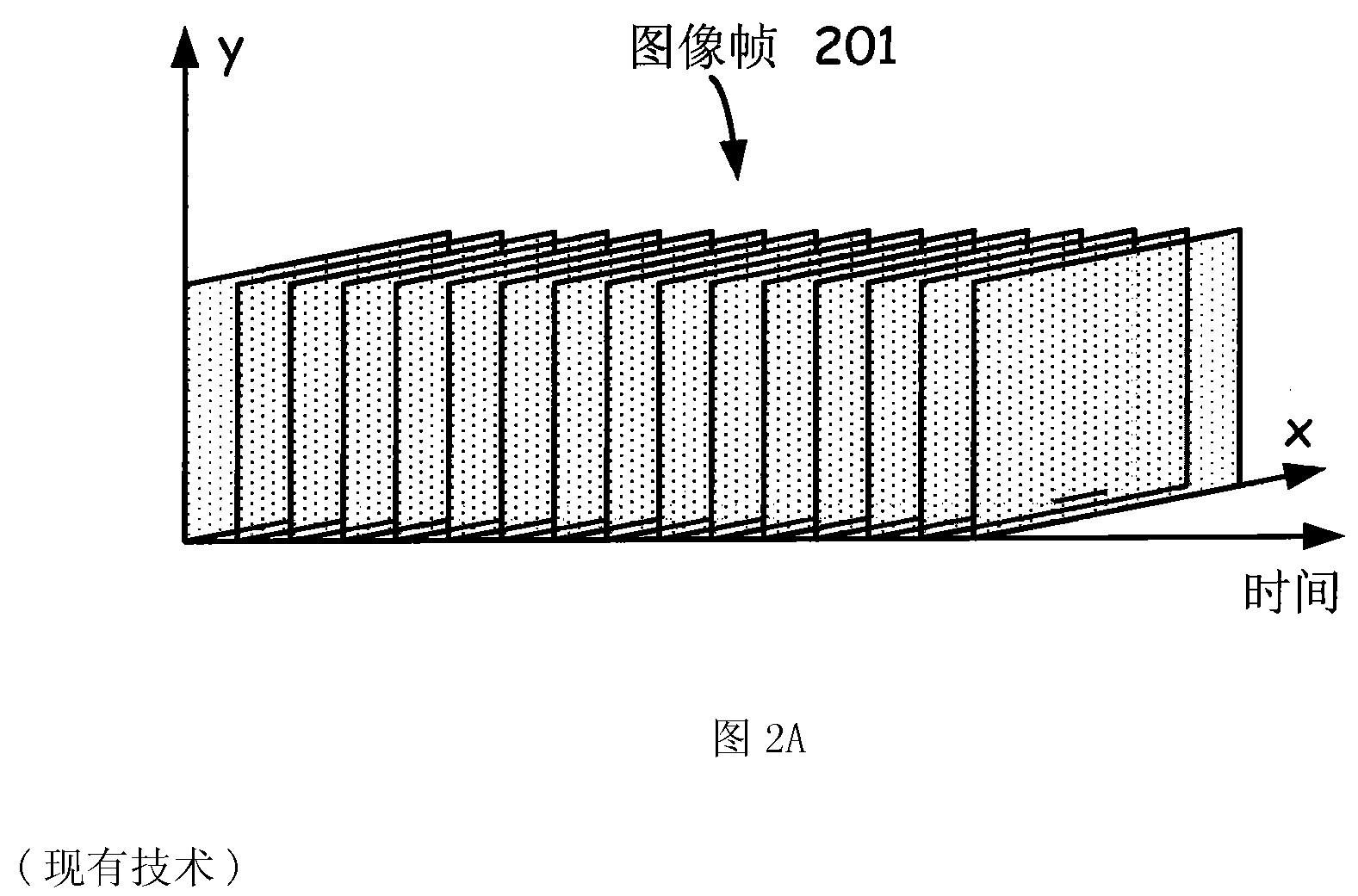

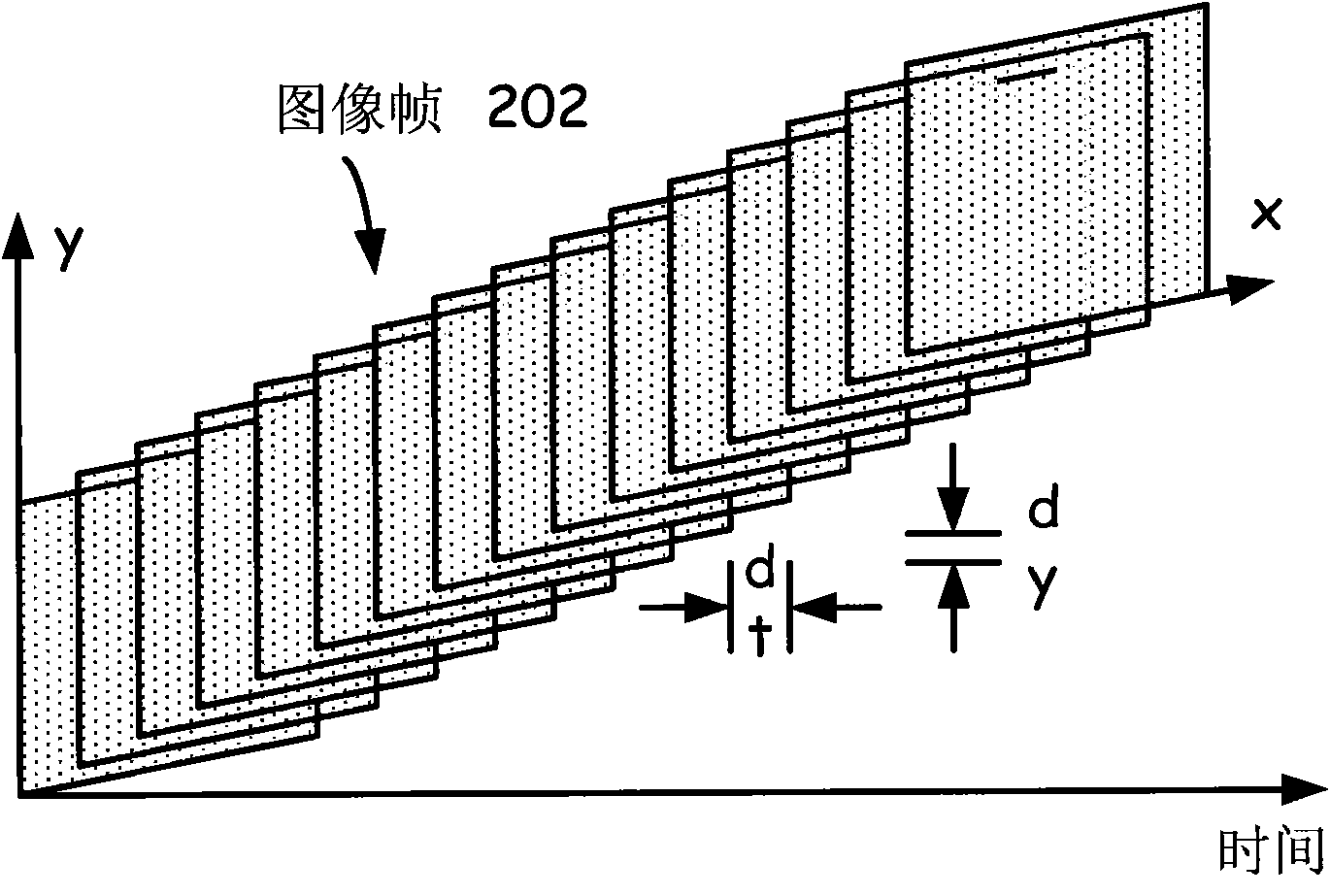

[0034] Traditional lock-in thermography requires the specimen to remain stationary while the infrared camera acquires the required number of images for lock-in integration. After one set of images has been acquired for one location on the sample, the sample is repositioned to acquire infrared images for a completely different location. This quiescent and repositioning time significantly reduces inspection throughput.

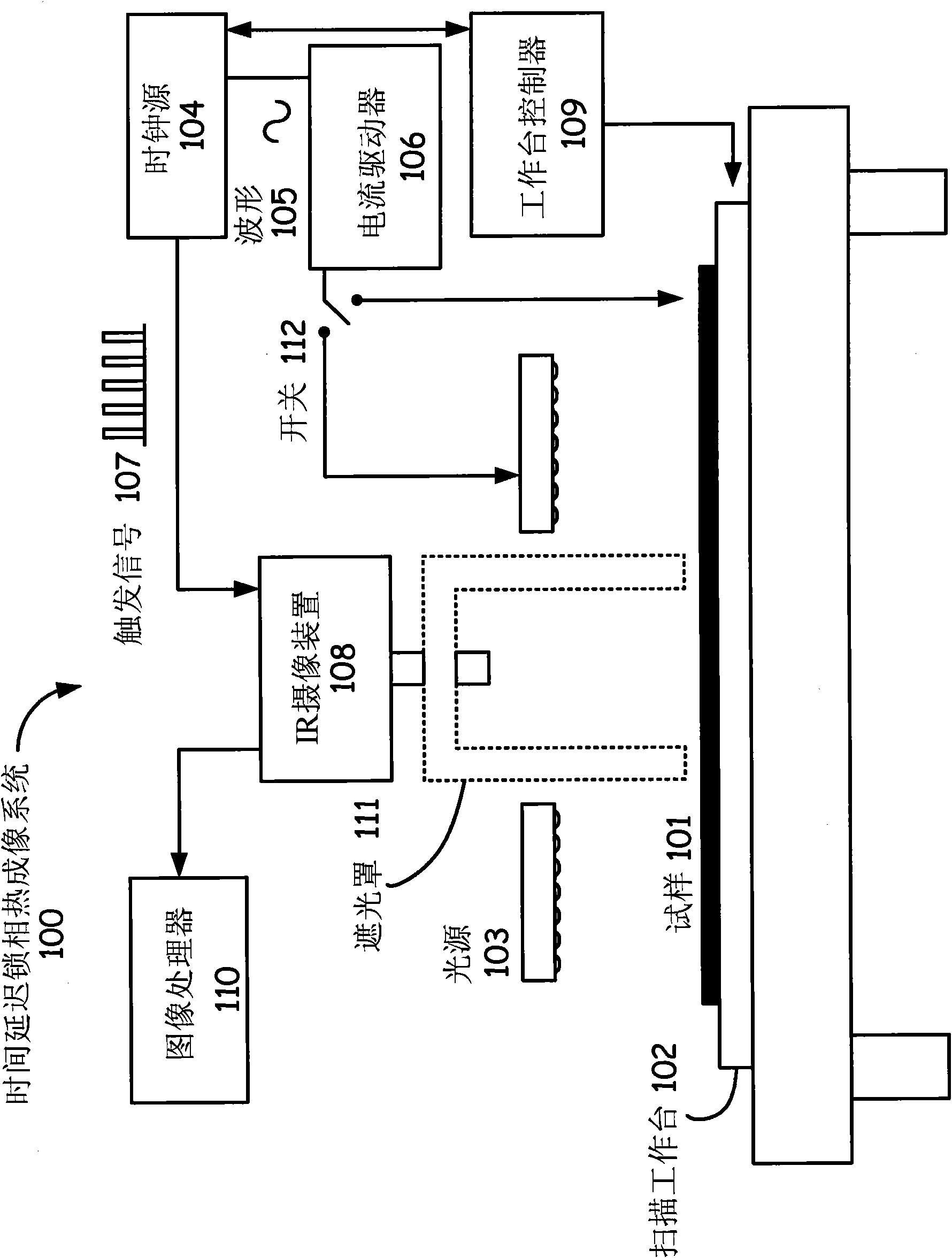

[0035] figure 1 Illustrated is an exemplary time-delay lock-in thermography system 100 that can significantly increase inspection throughput. In such an embodiment, sample 101 is placed on x-y scanning stage 102 . Applying modulation to a sample can be accomplished optically (eg, by using a modulated illumination source) or electronically (eg, by directly applying electrical current modulation to the sample). In one embodiment, switch 112 may be used to selectively connect current driver 106 to light source 103 or directly to sample 101 . In other embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com