Substrate for an organic light-emitting device, and organic light-emitting device incorporating it

A technology of organic light-emitting devices and substrates, which is applied in organic semiconductor devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of expensive and complicated photolithography methods, and achieve the effect of improving and satisfying the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

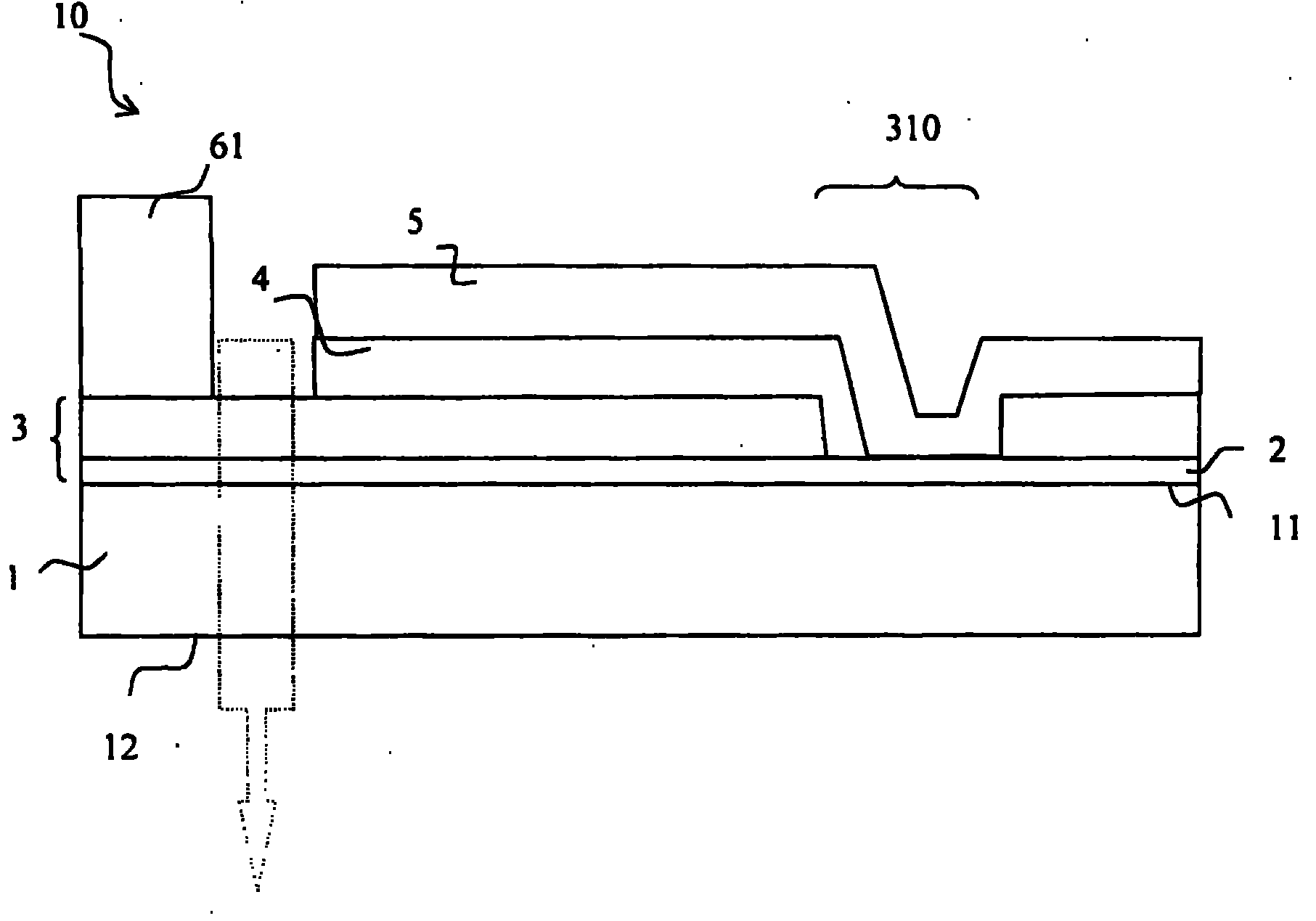

[0262] figure 1 is highly illustrative. It shows an organic light-emitting device 10 in cross-section (emitting through a substrate or "bottom emitting"), comprising in succession:

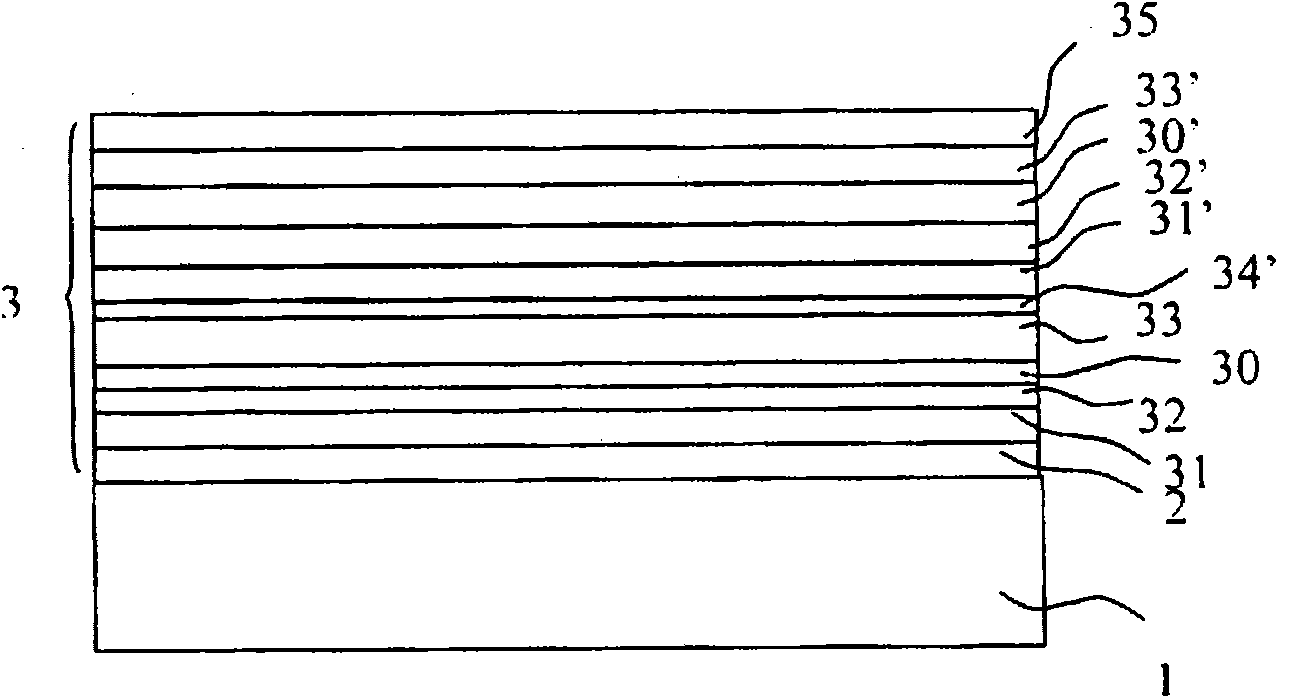

[0263] - a flat substrate 1 of optionally transparent or extra-transparent soda-lime-silica glass, for example starting from 0.7 mm in thickness, with a first and a second main face 11, 12, the first main face 11 first comprising a (semi)transparent The lower electrode 3, the lower electrode 3 comprises a stack of the following layers (see figure 2 ):

[0264] - an anti-reflection sublayer comprising:

[0265] - the base layer 2, deposited directly on the first main face 11, is made of silicon nitride and covers substantially the entire first main face 11;

[0266] - made of Sn doped with antimony Sb y Zn z o x making a first smoothing layer 31 which, as a variant, can be deposited directly on the face 11;

[0267] - ZnO doped by aluminum x The produced first contact layer 32;

[0268] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com