Semiconductive shielding composite material, preparation method thereof and application thereof in power cables

A composite material and semi-conductive technology, which is applied in the field of semi-conductive shielding composite material preparation for power cables, can solve the problems of large amount of carbon black filling, unsatisfactory performance and easy agglomeration of semi-conductive shielding materials, so as to improve the electrical conductivity and mechanical properties. The effect of excellent performance, mechanical properties and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

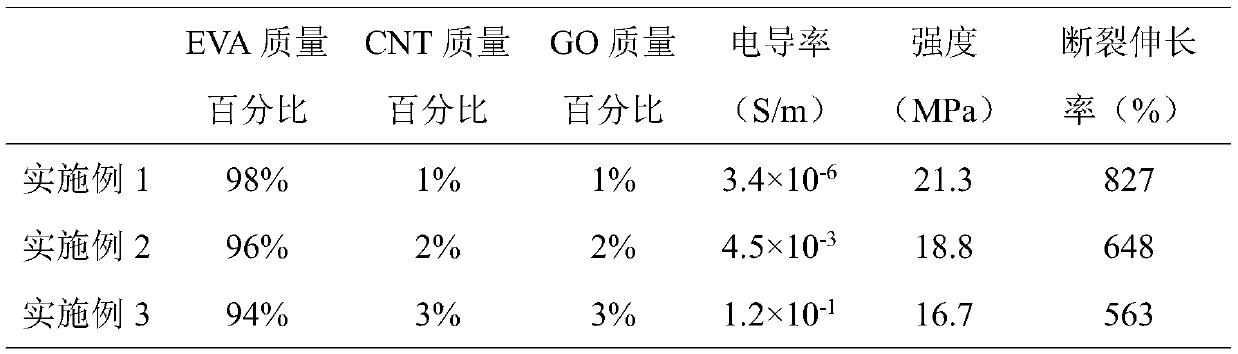

[0042] The mass percentage of main raw materials is as follows: EVA98%; CNT 1%; GO 1%;

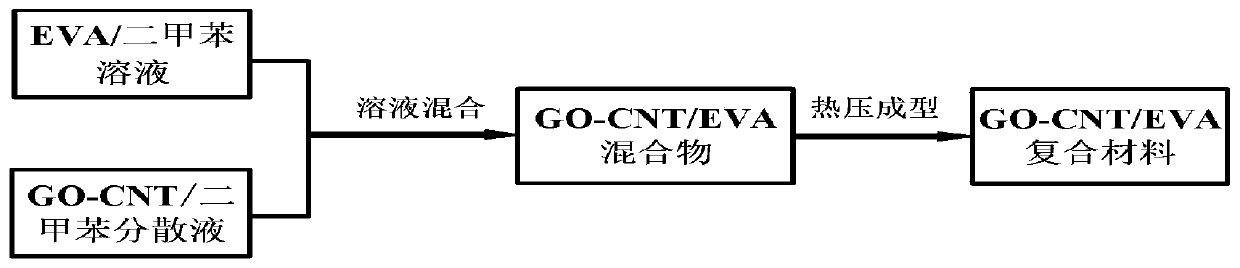

[0043] The operation steps adopt:

[0044] (1) Preparation of GO-CNT / EVA mixture: First, EVA was added into xylene and mechanically stirred at 60°C for 30 minutes to obtain EVA solution, then the GO-CNT / xylene uniform dispersion solution obtained after ultrasonication for 10 minutes was added to EVA solution, Continue stirring and mixing for 30 minutes to obtain a GO-CNT / EVA mixture, and finally pour the mixture into ethanol for flocculation and drying to obtain a GO-CNT / EVA mixture;

[0045] (2) Compression molding: The GO-CNT / EVA mixture obtained in step (1) was preheated at 160 °C for 5 min, then hot-pressed at 10 MPa for 10 min, and finally cooled to room temperature to obtain the target product.

Embodiment 2

[0047] Others are the same as in Example 1, the ratio of raw materials is EVA96%; CNT 2%; GO 2%;

Embodiment 3

[0049] Others are the same as in Example 1, the ratio of raw materials is EVA94%; CNT 3%; GO 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com