Industrial production method for extracting natural purple sweet potato coloring matter for food from edible purple sweet potato

A purple sweet potato pigment, purple sweet potato technology, applied in the directions of natural dyes, chemical instruments and methods, azo dyes, etc., can solve the problems of large-scale industrial production methods without a system, the production methods are available, etc., and achieve a simple and reasonable production process and environmental protection. The effect of low pollution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

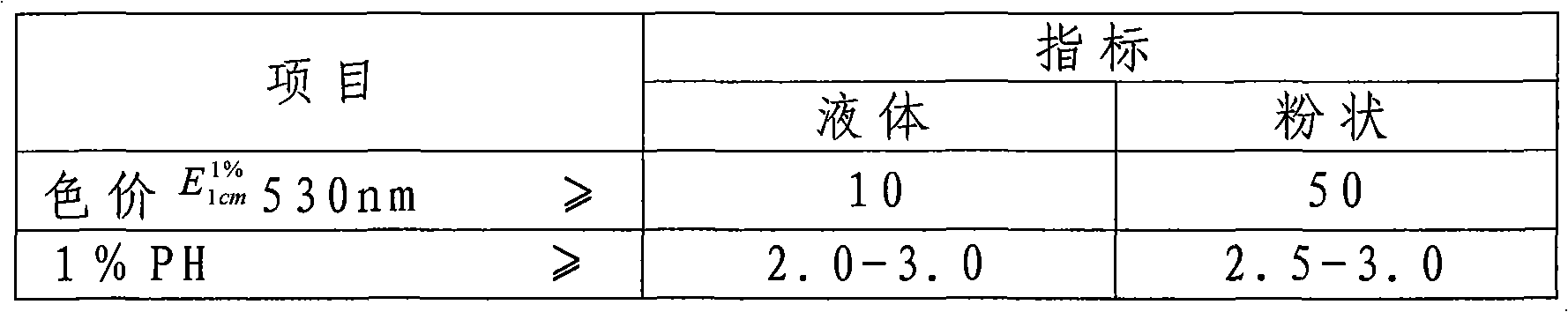

Examples

Embodiment 1

[0029] 1.0 tons of purple sweet potatoes are cleaned by a potato washing machine, and the purple sweet potatoes are cut into 3-5mm filaments with a shredding machine. Add 2.0 tons of aqueous solution, add 7 kg of food-grade hydrochloric acid, adjust the pH of the solution to 2.3, heat to 30 ° C, and stir for 3.5 hours to extract. After filtration, 1.8 tons of extracts were obtained, which were pumped into a sedimentation tank for static precipitation.

[0030] After 24 hours of static precipitation, the precipitated extract was released from the side port of the precipitation tank, filtered through a 0.45um membrane and pumped into a macroporous adsorption resin column for pigment adsorption at a flow rate of 350L / h, and the adsorption temperature was controlled at 25°C. After the adsorption is completed, use 2 times the volume of the resin to wash the resin, then add 2 times the volume of the resin column for ethanol analysis, the content is 50%, and obtain 0.5 tons of analys...

Embodiment 2

[0034] 1.0 tons of purple sweet potatoes are cleaned by a potato washing machine, and the purple sweet potatoes are cut into 3-5mm filaments with a shredding machine. Add 2.5 tons of aqueous solution, add 6 kg of food-grade hydrochloric acid, adjust the pH of the solution to 2.6, heat at 35° C., and stir for extraction for 4 hours. After filtration, 2.2 tons of extracts were obtained, which were pumped into a sedimentation tank for static precipitation.

[0035] After static precipitation for 24 hours, the precipitated extract was released from the side port of the precipitation tank, filtered through a 0.45um membrane and then pumped into a macroporous adsorption resin column for pigment adsorption at a flow rate of 350L / h, and the adsorption temperature was controlled at 30°C. After the adsorption is completed, use 2 times the resin volume to wash the resin, then add 2 times the resin column volume for ethanol analysis, the content is 60%, and obtain 0.8 tons of analysis sol...

Embodiment 3

[0039] 1.0 tons of purple sweet potatoes are cleaned by a potato washing machine, and the purple sweet potatoes are cut into 3-5mm filaments with a shredding machine. Add 3.0 tons of aqueous solution, add 5 kg of food-grade hydrochloric acid, adjust the pH of the solution to 2.8, heat at 40°C, and stir for extraction for 5 hours. After filtration, 2.7 tons of extracts were obtained, which were pumped into a sedimentation tank for static precipitation.

[0040] After static precipitation for 24 hours, the precipitated extract was released from the side port of the precipitation tank, filtered through a 0.45um membrane and pumped into a macroporous adsorption resin column for pigment adsorption at a flow rate of 350L / h, and the adsorption temperature was controlled at 35°C. After the adsorption is completed, use 2 times the resin volume to wash the resin, then add 2 times the resin column volume for ethanol analysis, the content is 70%, and obtain 0.5 tons of analysis solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com