chain tensioner

A chain tensioner and tensioner technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of increased manufacturing cost, complex structure, difficult to make an assembleable or disassembled shape, etc. , to achieve the effect of reducing manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

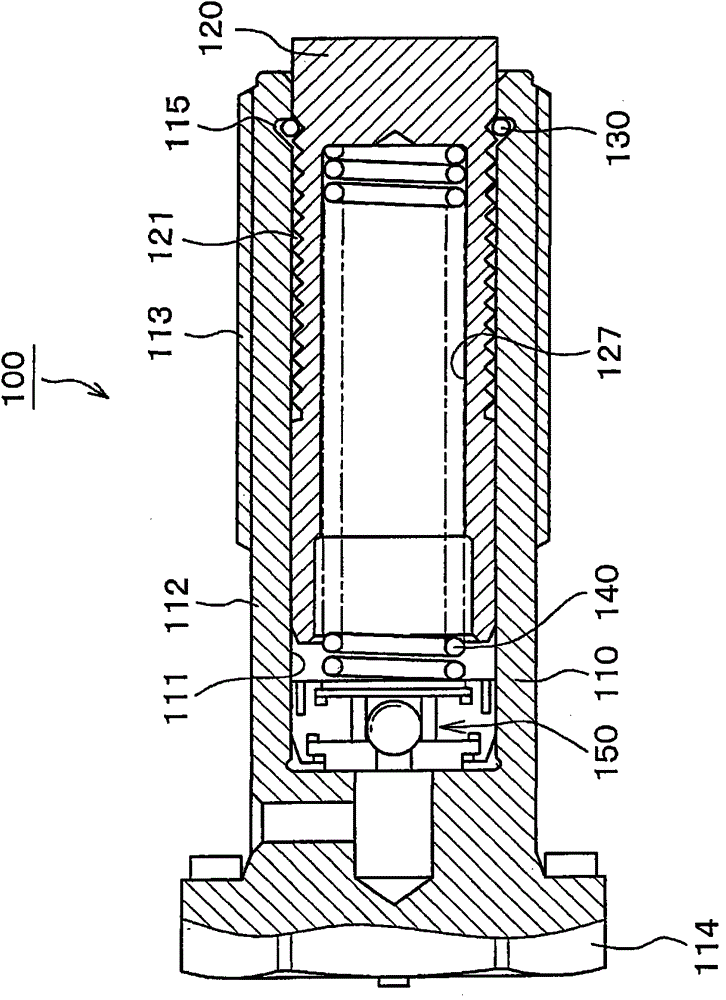

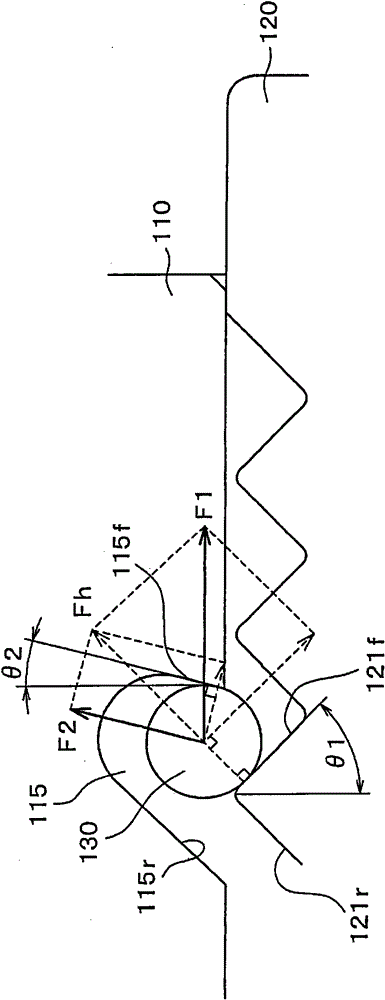

[0039] Hereinafter, a chain tensioner which is an embodiment of the present invention will be described based on the drawings.

[0040] The chain tensioner 100 of the present invention is, for example, a timing system for an engine.

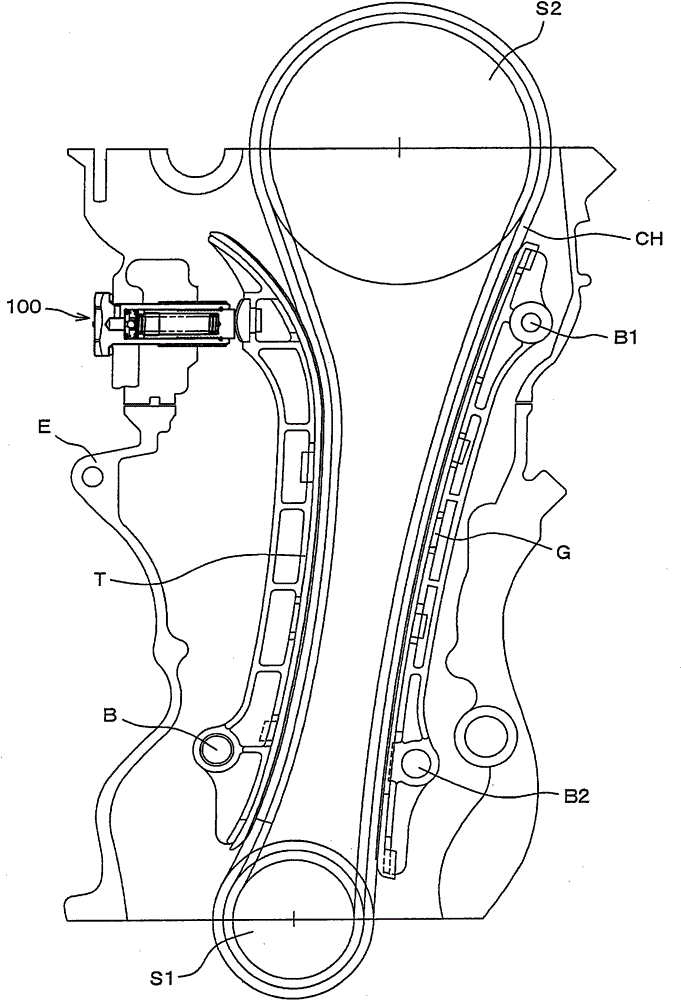

[0041] Such as figure 1 As shown, the timing system of the engine is to use the transmission chain CH, press contact with the tension rod T which properly maintains the tension of the transmission chain CH and guides the transmission chain CH, and the fixed guide part G which guides the operation of the transmission chain CH, wherein the transmission The chain CH is endlessly suspended between the driving sprocket S1 mounted on the crankshaft in the engine room formed by the engine block E and the driven sprocket S2 mounted on the camshaft.

[0042] The tension rod T is freely swingably installed in the engine room through the installation shaft B, and is pressed and applied by the chain tensioner 100 inserted and fixed on the engine block E fr...

Embodiment 2

[0067] Next, based on Figure 9 Another embodiment of the elastic ring is described.

[0068] In this embodiment, the elastic ring is composed of an annular ring 230, which is formed of an elastic material with a circular cross-section whose diameter can be reduced and expanded, and the rods 231, 232 are extended on the outer peripheral side. The tightening device main body 210 is provided with a notch communicating from a part of the outer periphery of the annular groove to the outside.

[0069] The outer peripheral diameter and inner peripheral diameter of the annular portion of the annular ring 230 are formed in the same manner as the above-mentioned C-shaped ring 130 .

[0070] In addition, one rod portion 231 is extended to the outside through the notch, and the other rod portion 232 is formed in an L-shape so that movement of the annular ring 230 in the circumferential direction is restricted within the notch.

[0071] Thereby, diameter expansion and contraction can be...

Embodiment 3

[0074] based on Figure 10 Still another embodiment of the elastic ring will be described.

[0075] In this embodiment, the elastic ring is composed of an annular ring 330. The annular ring 330 is formed of an elastic material with a circular cross-section whose diameter can be reduced and expanded, and the rods 331, 332 are extended on the outer peripheral side. The tightening device main body 310 is provided with a notch communicating from a part of the outer periphery of the annular groove to the outside.

[0076] The outer peripheral diameter and inner peripheral diameter of the annular portion of the annular ring 330 are formed in the same manner as the above-mentioned C-shaped ring 130 .

[0077] In addition, the rods 331, 332 on both sides are bent in the shape of a crankshaft in the notch, and the front ends thereof extend to the outside of the main body 310 of the tensioner. Movement of the annular ring 330 in the circumferential direction is restricted.

[0078] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com