Papermaking fiber image measuring method

A technology of image measurement and fiber, which is applied in the measurement of length, fiber composition, wall cavity size and width, and can solve problems such as inability to measure, and achieve the effects of reducing measurement errors, reducing changes, and reducing the strength of film production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

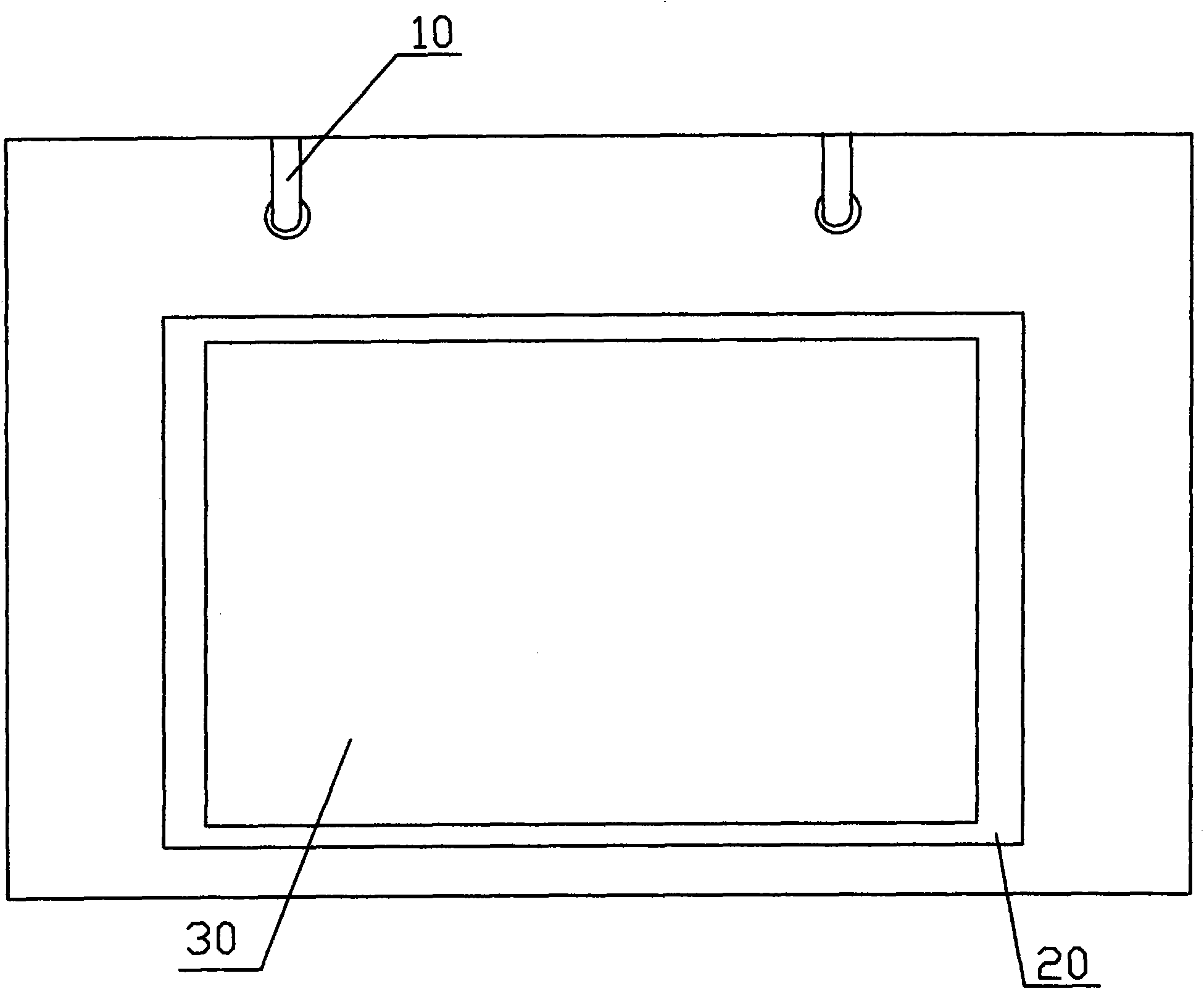

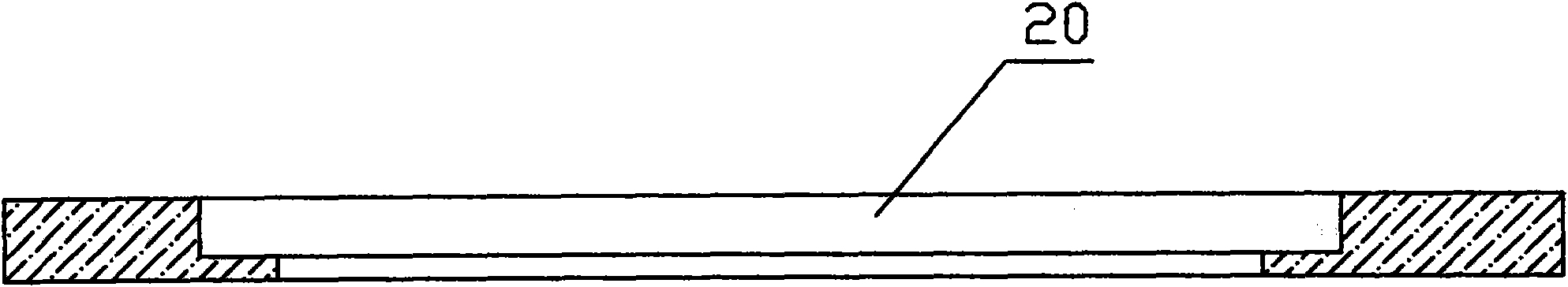

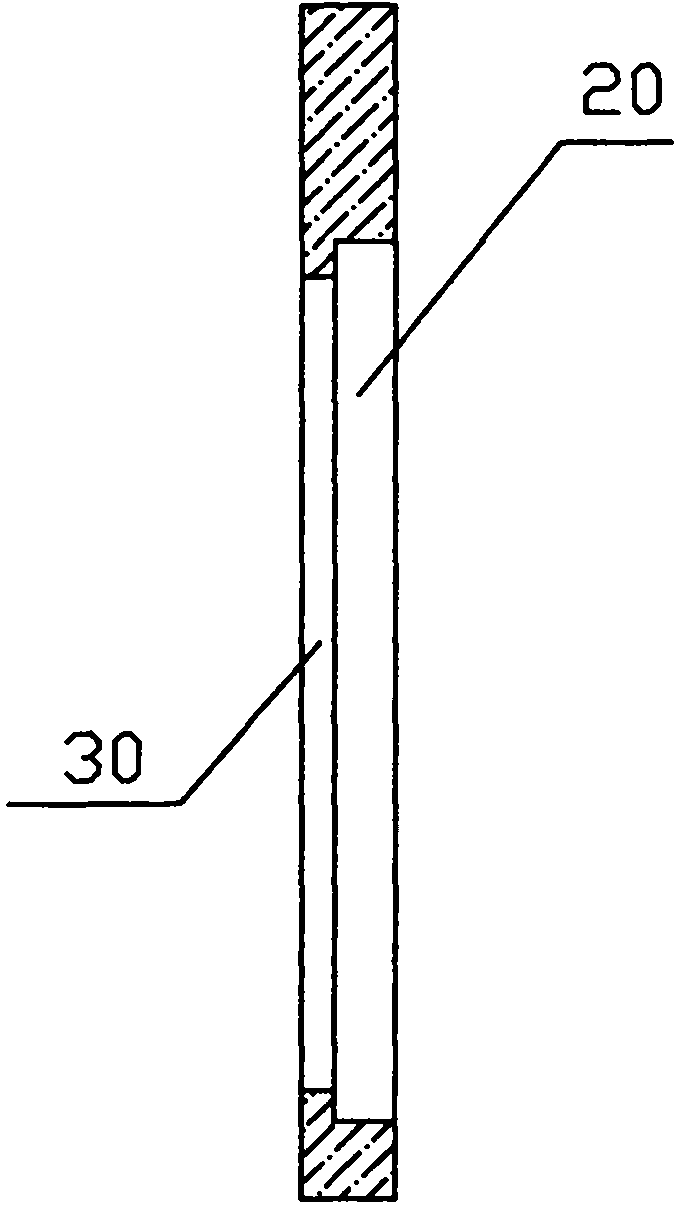

[0034] Part 1: Measurement of paper fiber length and width

[0035] The first step: Gel method to make tablets:

[0036] The steps of the method for preparing tablets by the gel method of the present invention: obtain a paper or pulp fiber sample according to the industry standard QB / T 2597-2003 papermaking fiber length measurement method, or disperse the undispersed raw material or pulp fiber sample to obtain fully dispersed For the wet pulp sample, knead the above wet pulp sample dry by hand; take about 1g of wet pulp, add 0.05 to 1 gram of dark or blue-black dyeing agent and about 0.5ml of water, mix evenly, heat to 90 degrees, and place it for a few minutes. Rinse the pulp with clean water to remove excess dye and dry it by hand. Then take about 10 mg of the slurry dyed into a dark color and place it in a glass bottle with a cover, add 5-20 ml of gel (composed of 0.5-3.5% agar and other seaweed gel solutions), heat it to a flowing liquid, and shake the suspension fully. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com