Method for preparing multiwall carbon nanotube-supported titanium dioxide catalyst

A technology of multi-walled carbon nanotubes and supported catalysts, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of uneven TiO and achieve strong operability and simple methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

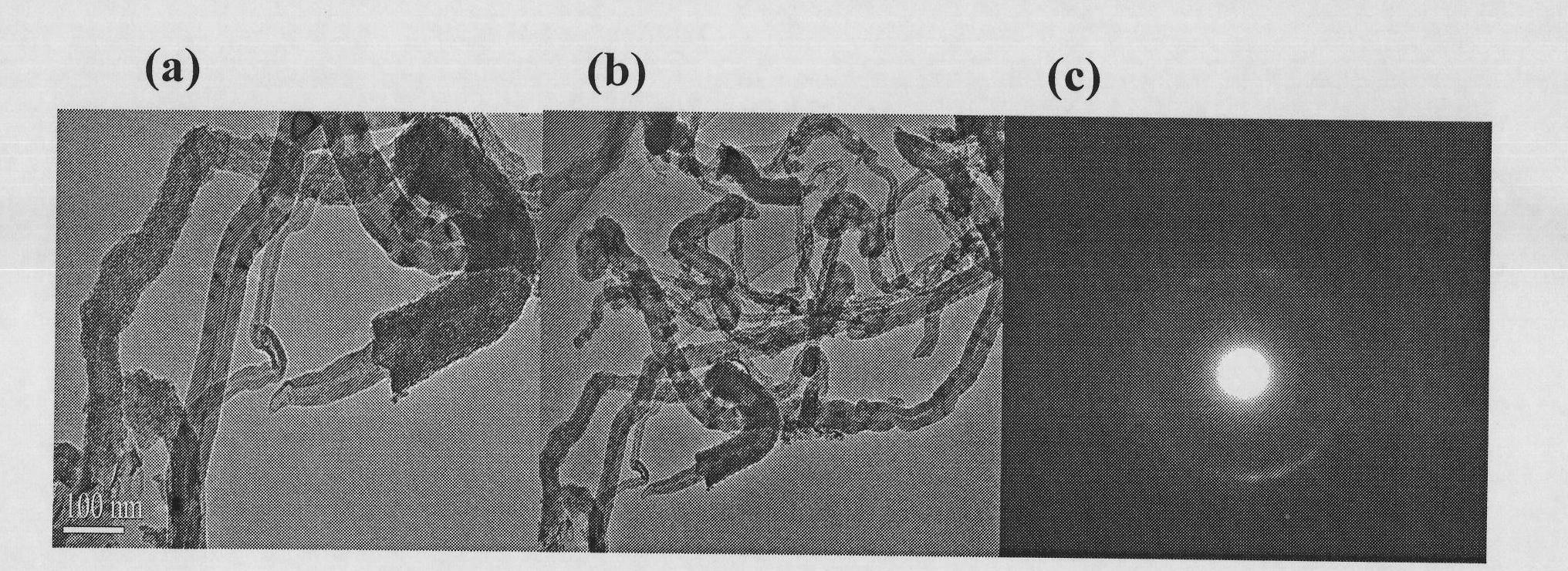

[0037] A) Ultrasonic dispersion: 0.1g of MWCNT (multi-walled carbon nanotubes, MWCNT; purchased from Nanotech Port Co, Shenzhen, Guangdong Province) and 0.6g of titanium sulfate were used as raw materials, respectively added to 20ml of methanol, and ultrasonically dispersed for 30min; Mix the above two solutions, and disperse by ultrasonic for 30min and magnetic stirring for 30min again at 35°C;

[0038] B) Solvothermal reaction: transfer the solution obtained in step A into a polytetrafluoroethylene tank and seal it, and then adopt a solvothermal method to prepare the loaded nanocomposite. The specific solvothermal conditions are as follows: from 35°C to 150°C, the heating rate is 1.0-2.0°C / min, then stored at 150°C for 5 hours, and then cooled to room temperature at a rate of 0.5-1.5°C / min;

[0039] C) Catalyst washing: in the sand core funnel connected to the vacuum pump, the mixed solution obtained in step B was repeatedly washed with secondary deionized water for 1 hour t...

Embodiment 2

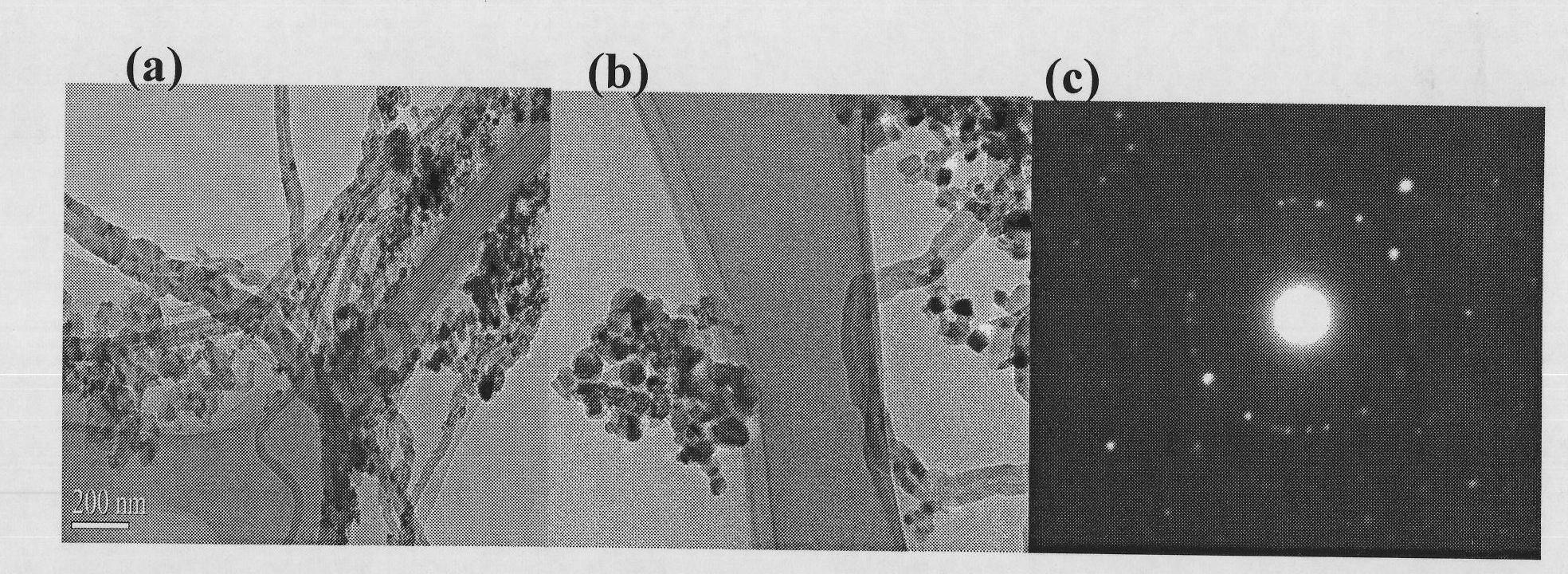

[0042] A) Ultrasonic dispersion: Take 0.1g P25 and 0.6g CNT as raw materials, add them to 20ml of water respectively, and after 30min ultrasonic dispersion, mix the above two solutions; ultrasonically disperse again at 35°C for 30min, and disperse by magnetic stirring for 30min;

[0043] B) Hydrothermal reaction: The solution obtained in step A is transferred into a polytetrafluoroethylene tank and sealed, and then the loaded nanocomposite is prepared by a hydrothermal method. The specific hydrothermal conditions are as follows: from 35°C to 150°C, the heating rate is 1.0-2.0°C / min, then stored at 150°C for 5 hours, and then cooled to room temperature at a rate of 0.5-1.5°C / min;

[0044] C) catalyst washing: in the sand core funnel connected to the vacuum pump, the mixed solution obtained in step B was repeatedly washed with secondary deionized water for 1 hour to remove various residual impurities, and then vacuum-dried for 12 hours to obtain the supported catalyst; Finally, ...

Embodiment 3

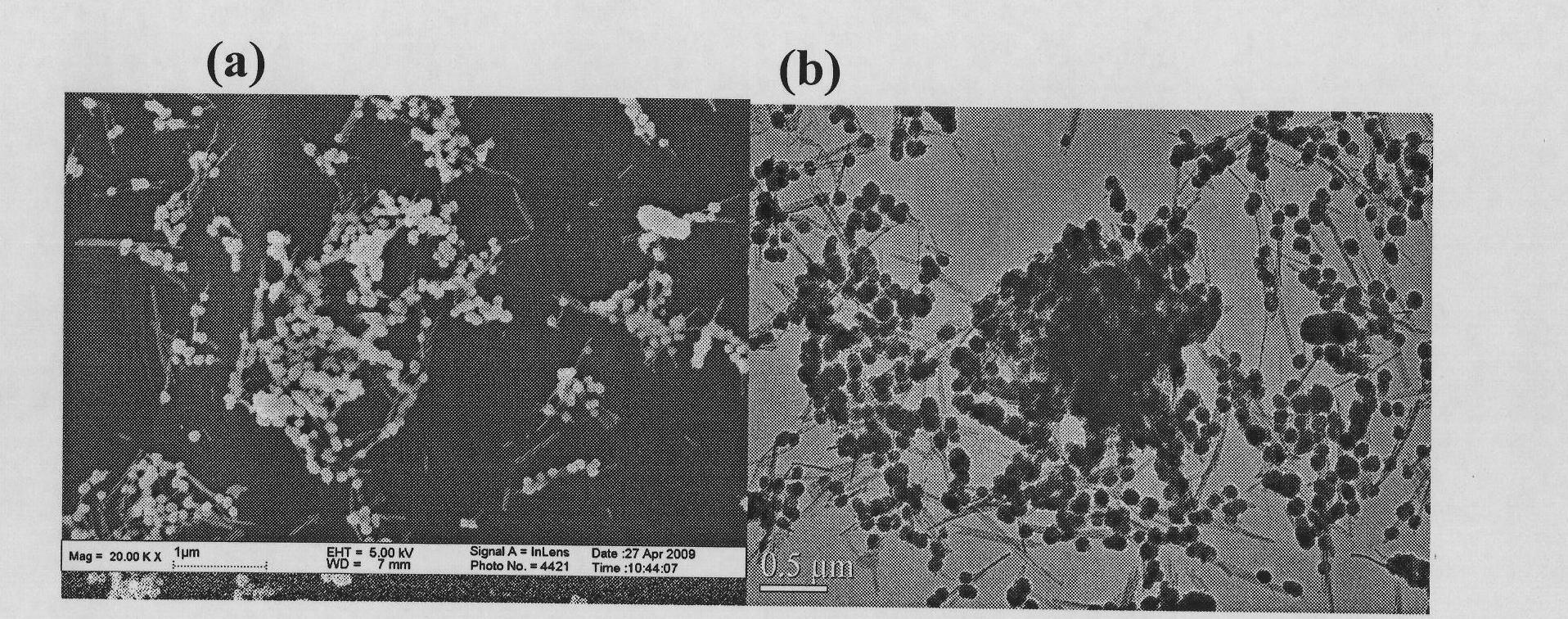

[0047] A) Ultrasonic dispersion: 0.1g of attapulgite and 0.6g of titanium sulfate were used as raw materials, respectively added to 20ml of water, and ultrasonically dispersed for 30min; the above two solutions were mixed, ultrasonically dispersed for 30min again at 35°C, and magnetically dispersed for 30min. stirring and dispersing;

[0048] B) Hydrothermal reaction: The solution obtained in step A is transferred into a polytetrafluoroethylene tank and sealed, and then the loaded nanocomposite is prepared by a hydrothermal method. The specific hydrothermal conditions are as follows: from 35°C to 150°C, the heating rate is 1.0-2.0°C / min, then after being stored at 150°C for 5 hours, the temperature is lowered to room temperature at a rate of 0.5-1.5°C / min;

[0049] C) Catalyst washing: in a sand core funnel connected to a vacuum pump, the mixed solution obtained in step B was repeatedly washed with secondary deionized water for 1 hour to remove various residual impurities, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com