Water-based ink for radio frequency identification antenna and preparation method thereof

A water-based ink, radio frequency identification technology, applied in the field of printing, can solve the problems of insufficient line conductivity and thickening of the line body, and achieve the effects of being conducive to environmental protection, low resistivity, and good adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The raw materials used in this embodiment and their percentages in the total mass of raw materials are respectively: 38% water-based polymer resin, 18% superconducting conductive carbon black: BP2000, 18% water, 10% ethanol, 5% antistatic agent, 6 % carbon black dispersant, 3% triethanolamine and 2% defoamer, then adopt the above-mentioned raw materials and proportioning to prepare according to the following steps:

[0029] (1) Mix water-based polymer resin, conductive carbon black, water, ethanol, antistatic agent and carbon black dispersant, fully stir and disperse evenly;

[0030] (2) Grind the dispersed material until the fineness does not exceed 10 μm, otherwise continue grinding until the fineness meets the requirements;

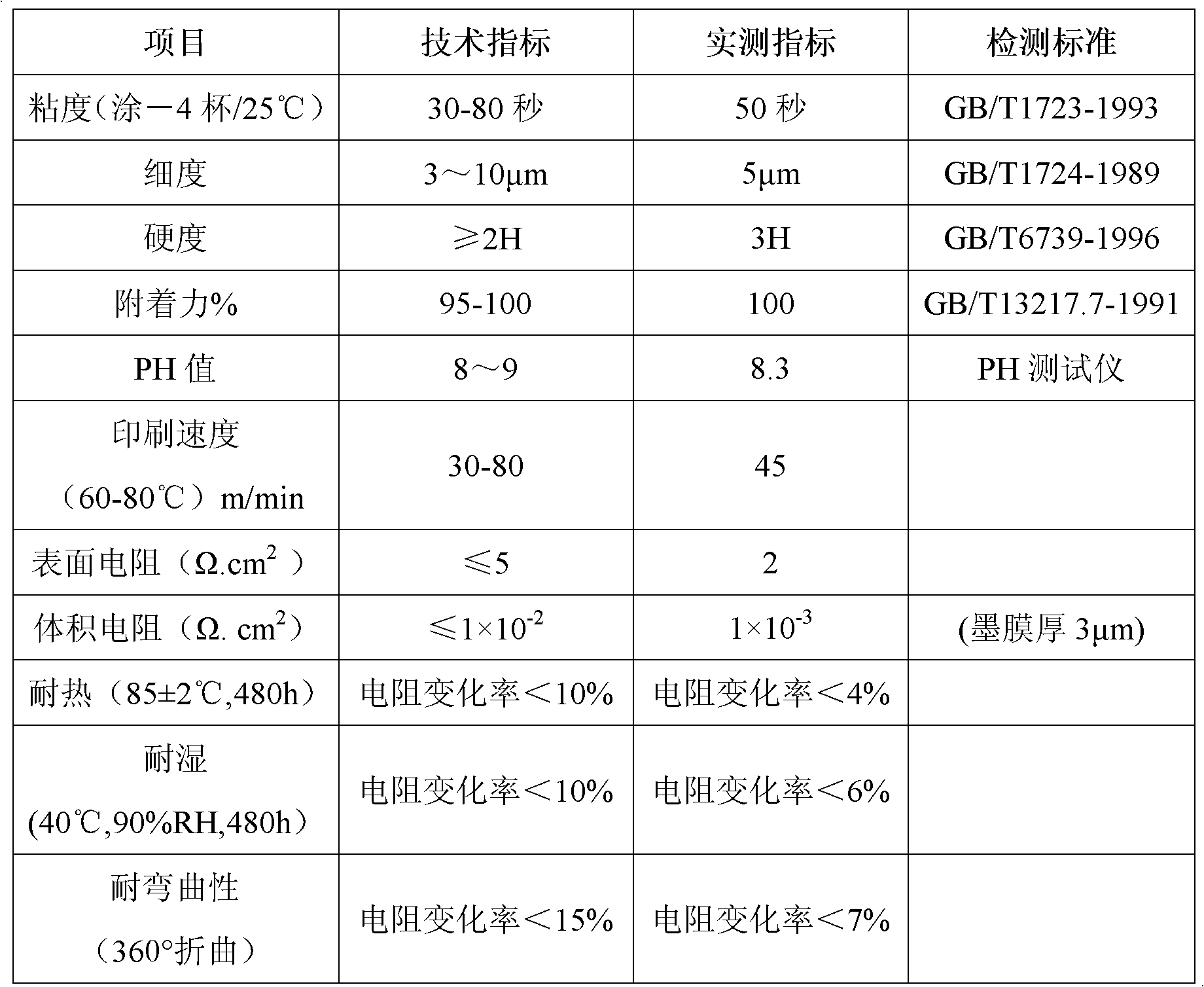

[0031] (3) Filter the ground material, and then disperse it evenly with triethanolamine and defoamer to prepare the water-based ink for RFID antenna. The RFID antenna was printed on the PET film with water-based ink by gravure printing, and the...

Embodiment 2

[0035] Each raw material used in the present embodiment and the percentage that accounts for the total mass of raw material are respectively: 42% water-based polymer resin, 20% HG-1F type conductive carbon black, 16% water, 9% ethanol, 4% antistatic agent, 5% % carbon black dispersant, 2% triethanolamine and 2% defoamer, then adopt the above-mentioned raw materials and proportioning to prepare according to the following steps:

[0036] (1) Mix water-based polymer resin, conductive carbon black, water, ethanol, antistatic agent and carbon black dispersant, fully stir and disperse evenly;

[0037] (2) Grind the dispersed material until the fineness does not exceed 10 μm, otherwise continue grinding until the fineness meets the requirements;

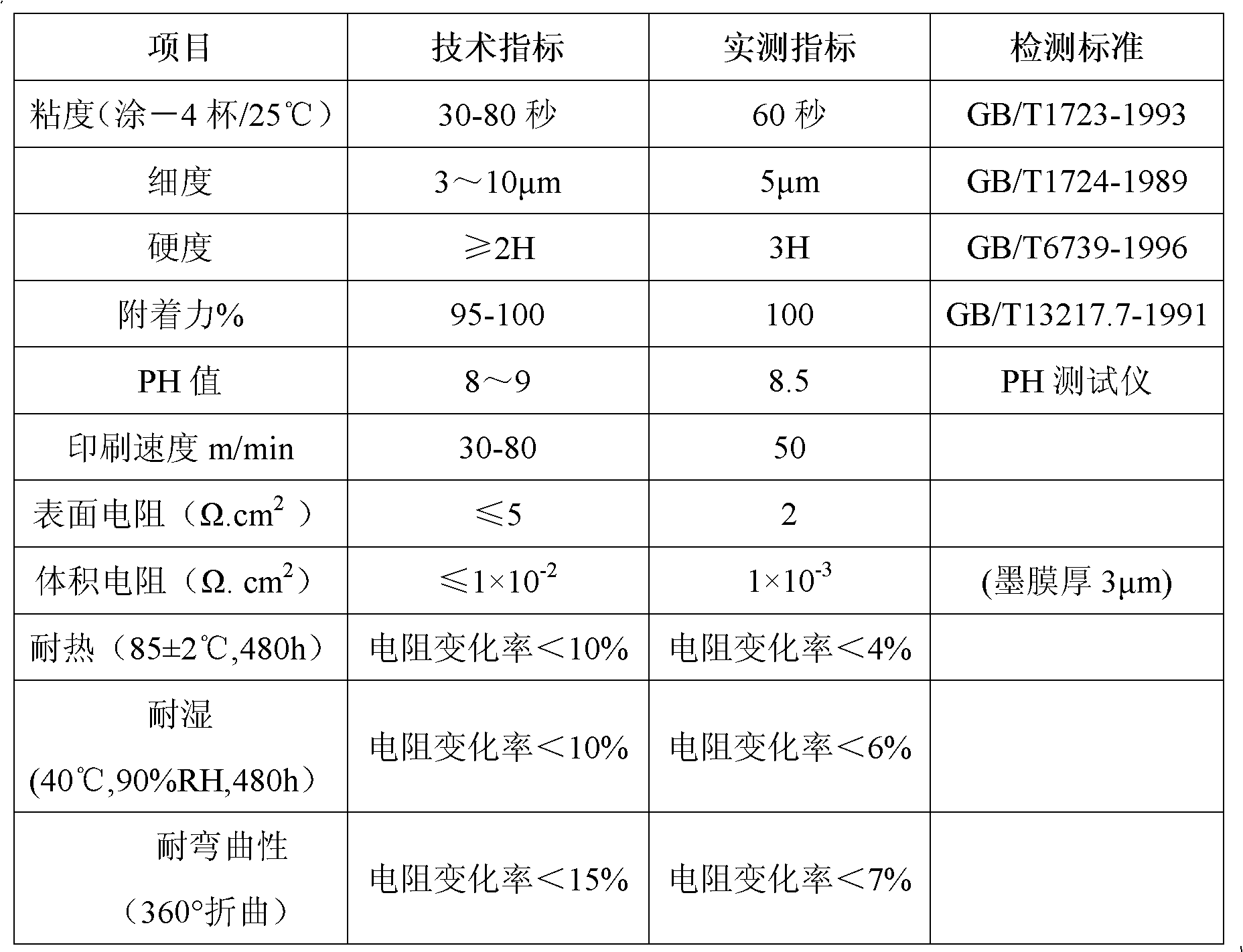

[0038] (3) Filter the ground material, and then disperse it evenly with triethanolamine and defoamer to prepare the water-based ink for RFID antenna. This product is printed on the upper paper by paper gravure printing, and made into a tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com