Carbon nano tube-polyurethane composite smart film and preparation method thereof

A technology of carbon nanotube film and dimming film, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of high cost and achieve the effect of low cost, simple structure and wide market demand prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

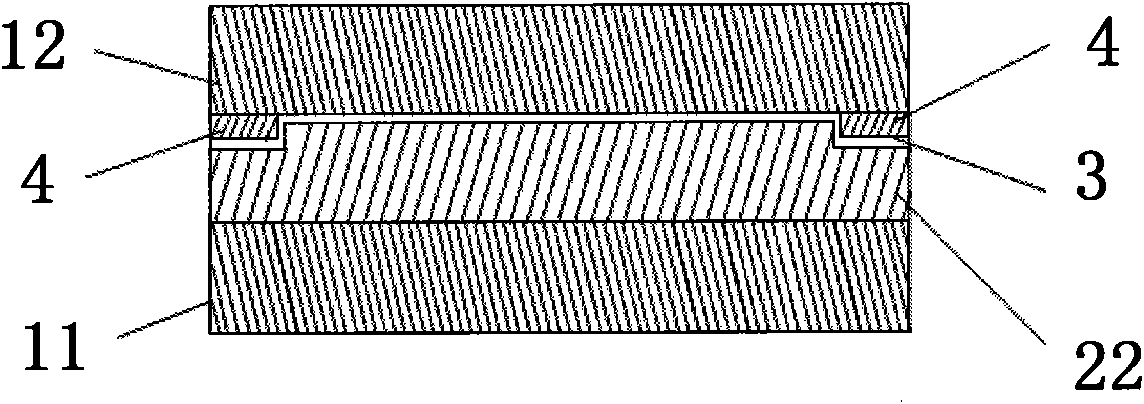

preparation example Construction

[0037] Of course, the above is only a superficial introduction to the preparation method of the composite dimming film, which further includes the initial selection and cleaning of the transparent base medium 11 as the substrate, and the shape memory polyurethane film before covering the carbon nanotube film. Heating to make it have a certain viscosity and other steps. In addition, in the above-mentioned steps of the preparation method of the present invention, there are further multiple preferred solutions, which are described in detail as follows:

[0038] First: The substrate used or the upper and lower transparent base media of the opposite substrate can be glass, plastic, rubber, etc. If glass is used as the transparent base medium, the composite dimming film has a rigid structure, and the finished product has high anti-damage and anti-corrosion performance, and is easy to prolong the service life; if soft transparent plastic or rubber such as transparent PET is used as t...

Embodiment 1

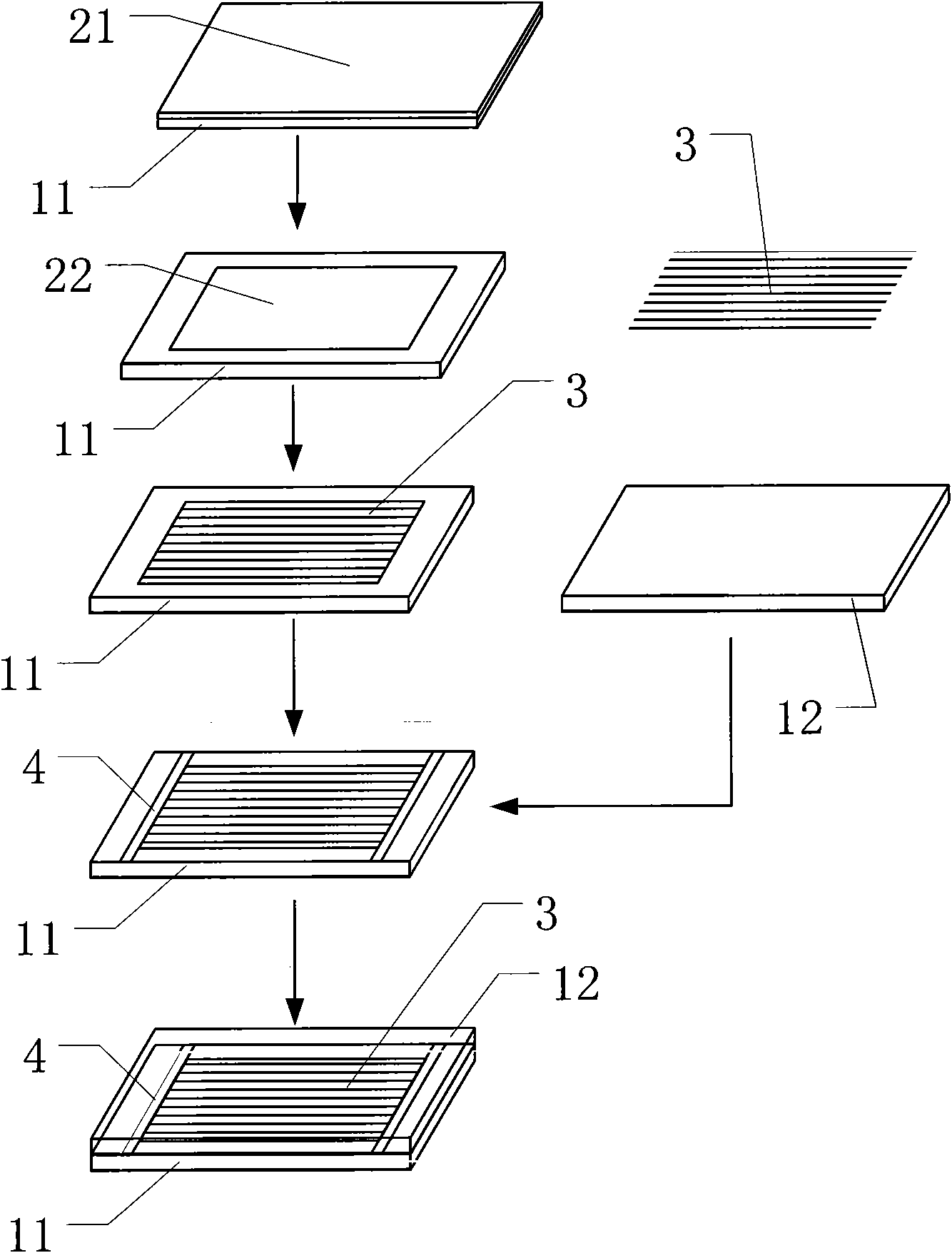

[0044] Such as figure 2 Shown is a schematic flow chart of a preparation example of carbon nanotube-polyurethane composite dimming film of the present invention, which includes the following steps:

[0045] Step 1, fully dissolving shape memory polyurethane (English abbreviation: SMPU) in N-methylpyrrolidone (NMP) to form a solution 21 with a concentration of 10%.

[0046] Step 2: Take a certain amount of SMPU / NMP solution 21 and slowly coat it on the pre-treated transparent glass slide (that is, the transparent base medium) to form a uniform and smooth liquid film on the surface of the glass slide. Finally, put the slide glass coated with the polyurethane solution into a blast drying oven, dry at 70°C for 48 hours, and then raise the temperature to 110°C for 24 hours.

[0047] Step 3, trimming the edge height of the SMPU film in the sample in step 2.

[0048] Step 4, place the SMPU / glass slide obtained in step 3 on a heating platform, and when the surface of the SMPU becom...

Embodiment 2

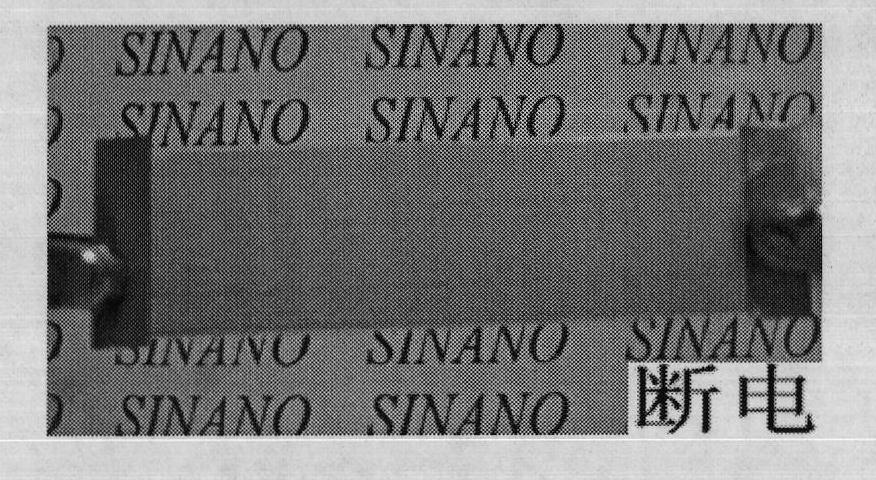

[0051] Fully dissolve SMPU in DMF (N, N-dimethylformamide) to form a saturated solution; add the required pigments (blue, brown, etc., see Figure 3) to the saturated solution, stir and mix evenly; Take a small amount of mixed solution and apply it on the surface of transparent PET film to form a flat and uniform liquid film; then put it in a blast drying oven at 70°C and dry it for 72 hours; take out the dried sample and simply modify the surface; In the state, the surface of the colored polyurethane is covered with a carbon nanotube film, terminal electrodes, and an upper transparent substrate—a transparent PET film in sequence; finally, the sample is fixed to obtain a colored flexible electroluminescent film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com