Dual-mode electric vehicle drive motor

A technology for driving motors and electric vehicles, applied in electric vehicles, motors, electrical components, etc., can solve problems such as additional power loss, complex electric drive and electronic control parts of electric vehicles, and difficulty in popularizing electric vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

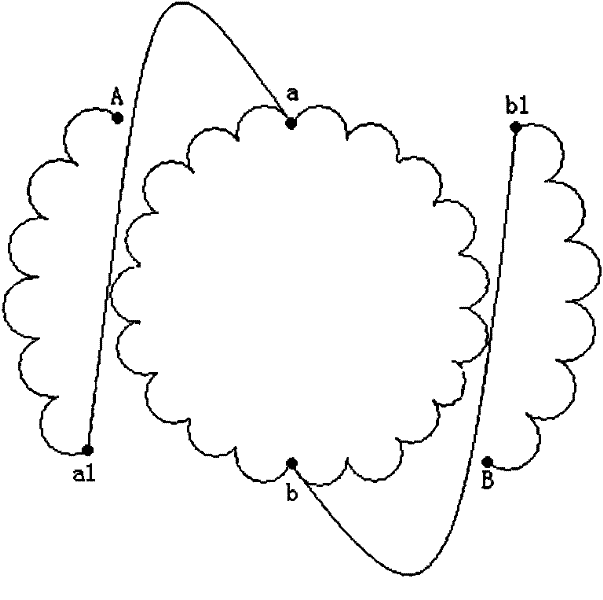

[0012] Take points a and b on the armature of the series-excited machine, determine that the armature of the series-excited machine becomes the reference point of the armature lead-out line of the alternator at the same time, and place the AC booster winding in the armature slot of the series-excited machine , one end a1 of one set of AC boost windings is connected to the reference point a of the series machine, and one end b1 of the other set of AC boost windings is connected to the reference point b of the series machine; two sets of AC boost windings The two terminals A and B of the terminal are connected to the rectification circuit. Through this method, the AC power whose amplitude is higher than the power supply voltage on the series excitation machine is directly obtained, and the AC power is controlled to be rectified, and directly fed to the power supply after rectification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com