Method for preparing microcapsule coated ammonium polyphosphate

A technology of coating ammonium polyphosphate and microcapsules, applied in the field of materials, can solve problems such as uneven distribution, agglomeration, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

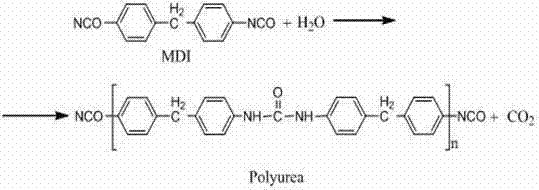

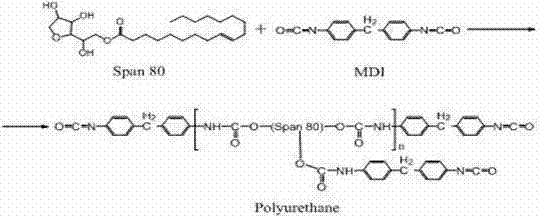

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of MCAPP containing water

[0027] First use H 2 O pre-impregnate the APP to provide conditions for the accumulation of Span 80 / 85 on the surface of the APP.

[0028] In Example 1, the following three mixtures are marked as W 11 , W 12 , W 13 :

[0029] W 11 : "APP Clay" (10g APP + 1g H 2 O).

[0030] W 12 : Span 80 / 85 (Span80:Span85=3:2; 5g) is dissolved in toluene (30ml).

[0031] W 13 : MDI (15g) and DBDL (0.78g) are dissolved in toluene (15ml).

[0032] The organic phase W 12 With W containing the core material 11 Stir at high speed for 30 min at room temperature. After APP with water on the surface is wrapped and dispersed by the mixed dispersant, add solution W 13 , Under the condition of high-speed stirring (2000r / min), the temperature is raised to 63°C to polymerize the mixed dispersant film wrapped on its surface, and the reaction is continued for 4h. After the reaction, the microcapsule slurry was gently poured out and washed with toluene and w...

Embodiment 2

[0034] Example 2: Preparation of MCAPP without water

[0035] In Example 2, the following 3 mixtures are marked as W 21 , W 22 , W 23 :

[0036] W 21 : APP paste (10g APP).

[0037] W 22 : Span 80 / 85 (Span80:Span85=3:2; 5g) is dissolved in toluene (30ml).

[0038] W 23 : MDI (2g) and DBDL (0.1g) are dissolved in toluene (15ml).

[0039] First use a thermostatic magnetic stirrer to remove the organic phase W 22 With W containing the core material 21 Stir at high speed for 30 min at room temperature. After APP coated with mixed dispersant on the surface is dispersed in toluene, add solution W 23 , Under the condition of high-speed stirring (2000r / min), the temperature is raised to 63°C to cause polymerization reaction of the mixed dispersant film wrapped on the APP surface, and the reaction continues for 4h. After the reaction, the microcapsule slurry was gently poured out and washed with toluene and water respectively to remove unreacted MDI and uncoated APP. The microcapsules after ...

Embodiment 3

[0041] Example 3: Preparation of MCAPP using acetone as organic solvent

[0042] Same as Example 1, first use H 2 O pre-soak APP to provide conditions for the aggregation of the mixed dispersant on the surface of APP.

[0043] In Example 3, the following three mixtures are marked as W 31 , W 32 , W 33 ,:

[0044] W 31 : "APP Clay" (10g APP + 1g H 2 O).

[0045] W 32 : Span 80 / 85 (Span80:Span85=3:2; 5g) is dissolved in acetone (30ml).

[0046] W 33 : MDI (15g) and DBDL (0.78g) are dissolved in acetone (15ml).

[0047] The organic phase W 32 With W containing the core material 31 Stir at high speed for 30 min at room temperature. After APP with water on the surface is wrapped and dispersed by the mixed dispersant, add solution W 33 , Under the condition of high-speed stirring (2000r / min), the temperature is raised to 54°C to polymerize the mixed dispersant film wrapped on the surface, and the reaction is continued for 4h. After the reaction, the microcapsule slurry was gently poured ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com