Pressure pipe type sewage treatment reactor

A sewage treatment and tubular reaction technology, applied in the field of environmental protection and sewage treatment, can solve the problems of unfavorable operation and management of sewage treatment reactors in small towns, complex operation management, high operating costs, etc., to enhance the mass transfer capacity and utilization of oxygen The effect of high efficiency, short technological process, reduced investment and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

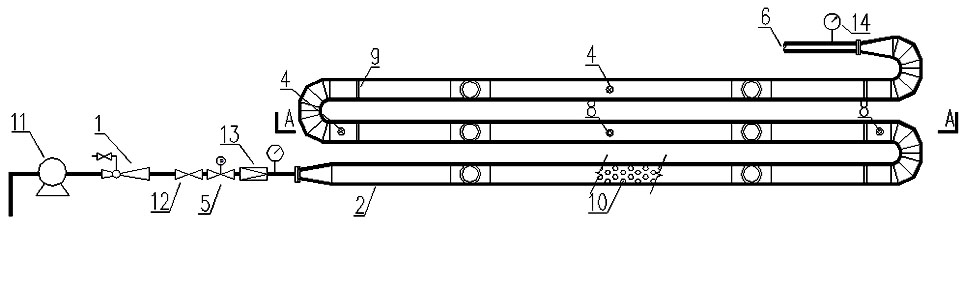

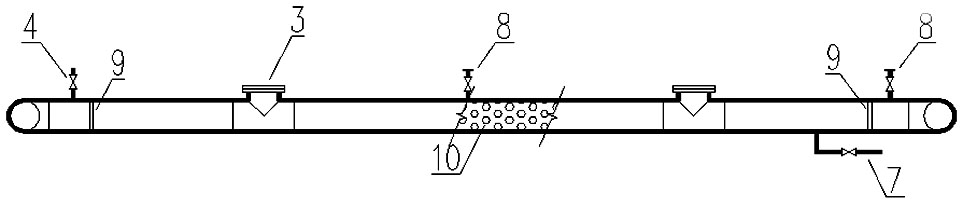

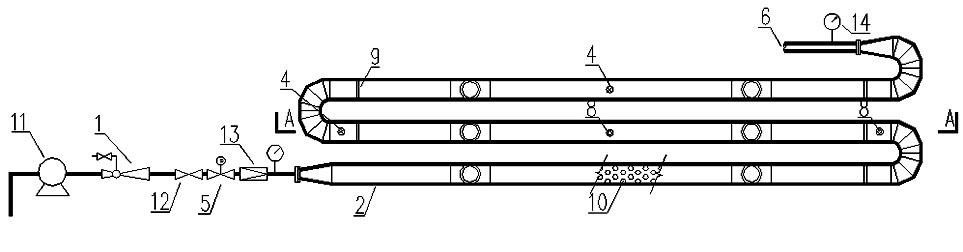

[0017] see figure 1 and figure 2 , the specific implementation of the pressure tubular sewage treatment reactor is as follows: the reactor includes negative pressure oxygenation equipment 1, pressure tubular reaction zone 2, filler input port 3, safety valve 4, pressure regulating valve 5, drain pipe 6, Mud discharge pipe 7 and exhaust valve 8 etc. The inlet water of the reactor is pressurized by the water pump 11, through the negative pressure oxygenation equipment 1 negative pressure oxygen inhalation, carrying a large amount of oxygen into the pressure tube reaction zone 2, and using the pressure regulating valve 5 on the water inlet pipe of the reaction zone to control the reaction work pressure in the area. The pressure reaction zone is composed of multiple pipe sections, each section is separated by a partition 9, and a suspended packing 10 is installed in the pipe through the filling opening 3. The gas produced by the anaerobic fermentation in the reaction zone is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com