Acrylic acid industry wastewater treatment process

A technology for industrial waste water and treatment process, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve problems such as difficult industrialization, incomplete degradation, and increased treatment costs. Achieve the effects of easy maintenance and management, convenient operation, and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

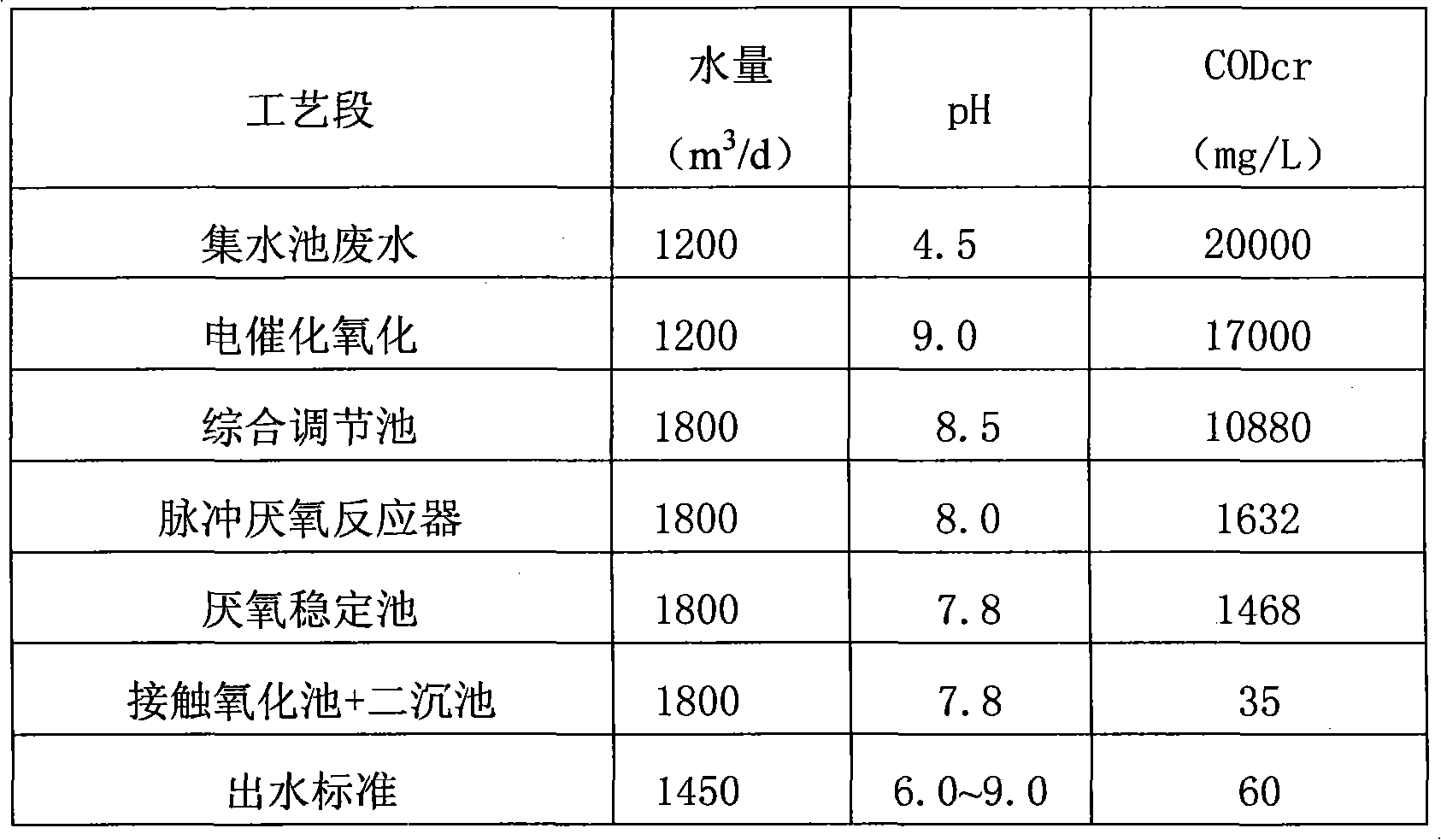

Embodiment 1

[0020] The wastewater from acrylic acid production flows through the sump to adjust the water volume, and then pumps it into the electrocatalytic oxidation device for reaction. The device uses carbon fiber as the cathode and cast iron as the anode. Most of the organic matter is removed or degraded in this device. The B / C of the effluent is changed from 0.01 Increased to 0.32, the electrocatalytic oxidation effluent enters the dechlorination pool, and the salts are effectively removed in the dechlorination pool, and the effluent of the dechlorination pool enters the comprehensive adjustment pool, adding 600m 3 For domestic sewage, adjust the water quality, water volume and pH. The effluent from the comprehensive adjustment tank enters the pulse anaerobic reaction tank. After 2 days of anaerobic treatment, the effluent enters the anaerobic stabilization tank for further anaerobic reaction. The effluent from the anaerobic stabilization tank enters the contact oxidation tank Aerobi...

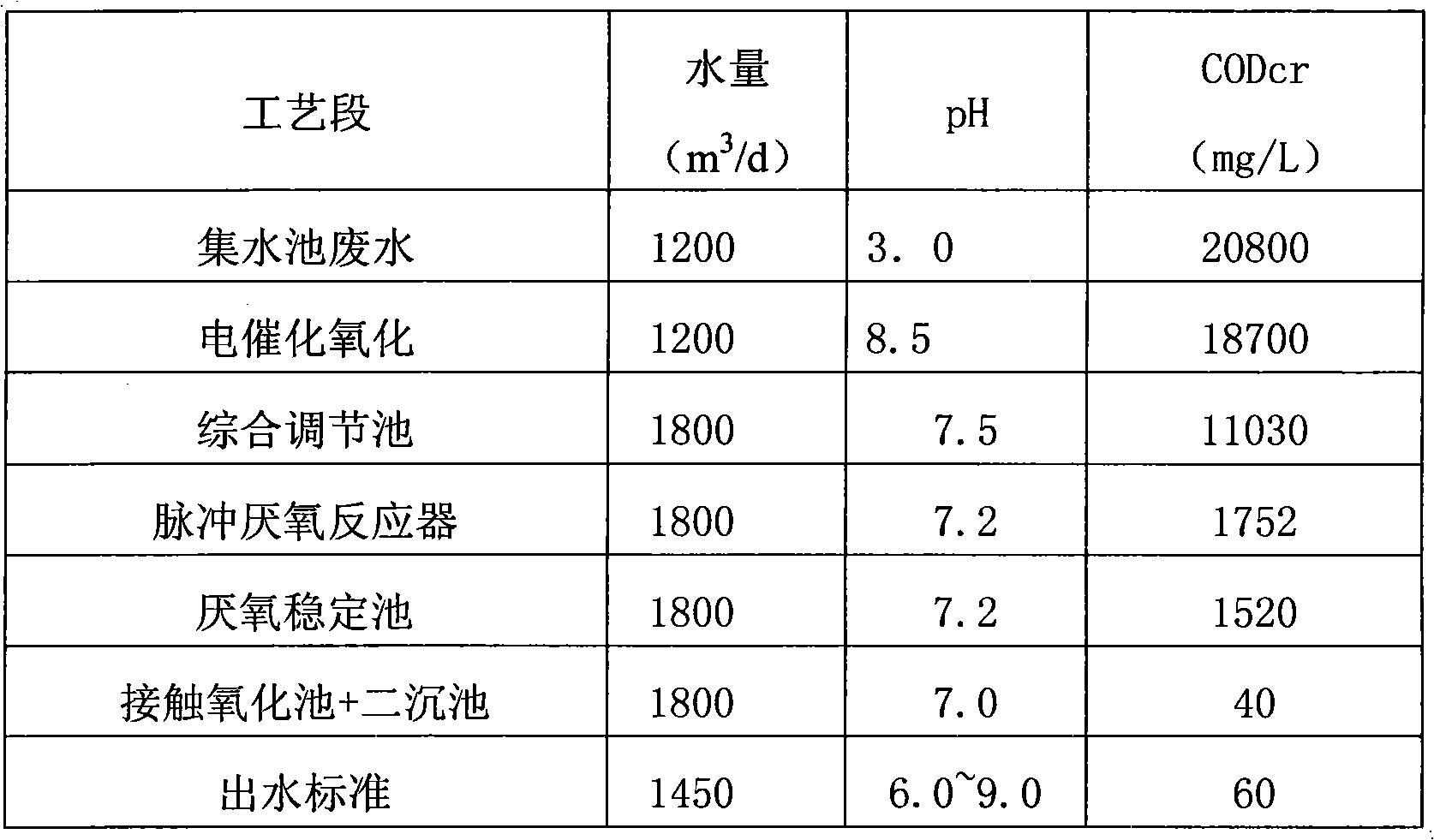

Embodiment 2

[0026] The waste water from acrylic acid production flows through the sump to adjust the water volume, and then pumps it into the electrocatalytic oxidation device for reaction. The device uses carbon fiber as the cathode and cast iron as the anode. Most of the organic matter is removed in this device, and the B / C of the effluent is increased from 0.02 to 0.4, the effluent from electrocatalytic oxidation enters into the comprehensive regulating pool, adding 600m 3 For domestic sewage, adjust the water quality, water volume and pH. The effluent from the comprehensive adjustment tank enters the pulse anaerobic reaction tank. After 2 days of anaerobic treatment, the effluent enters the anaerobic stabilization tank for further anaerobic reaction. The effluent from the anaerobic stabilization tank enters the contact oxidation tank Aerobic treatment is carried out, and the treated wastewater enters the secondary sedimentation tank for mud-water separation, and the sedimented wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com