Escherichia coli strain for high yield of Gamma-aminobutyric acid and method for producing Gamma-aminobutyric acid therefrom

A technology of aminobutyric acid and Escherichia coli, which is applied in the field of biochemistry, can solve the problems of low product concentration, low enzyme activity, and long reaction cycle, and achieve the effects of simple reaction system, simplified extraction process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

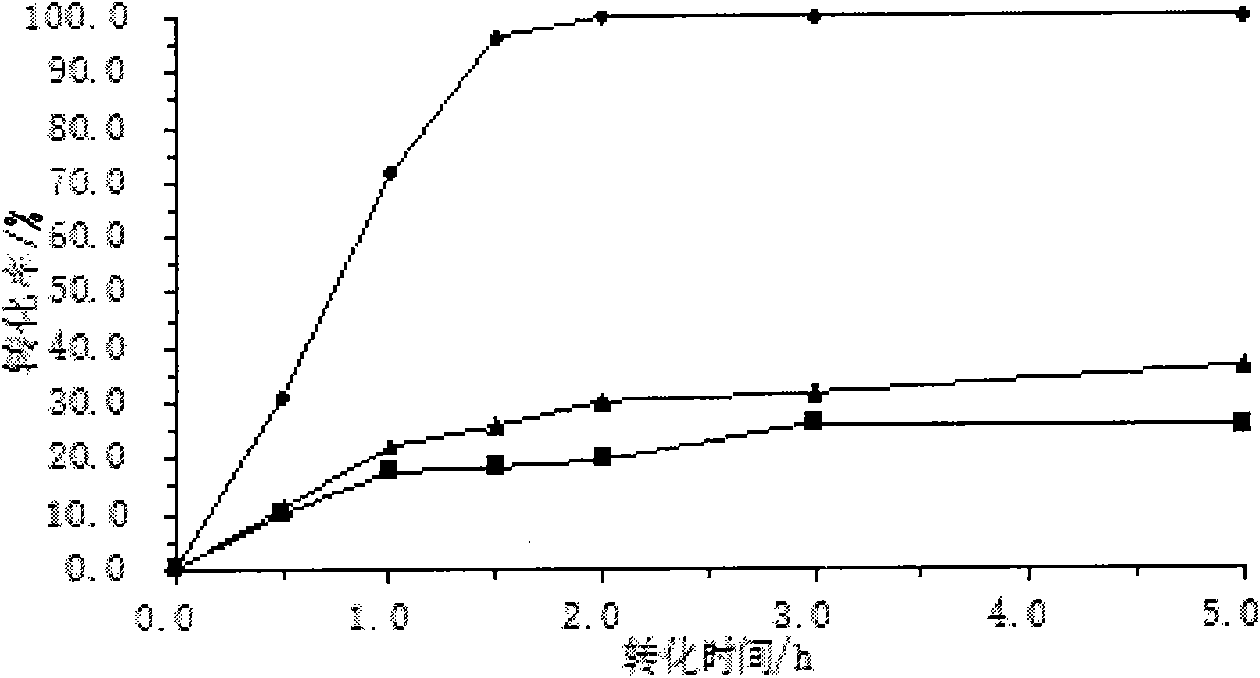

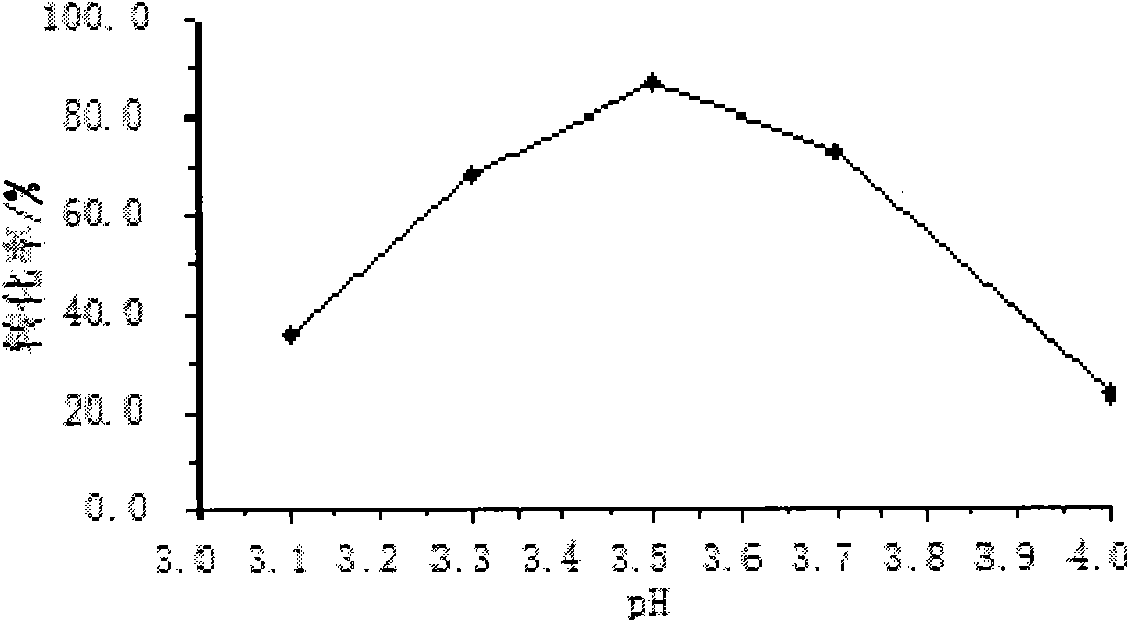

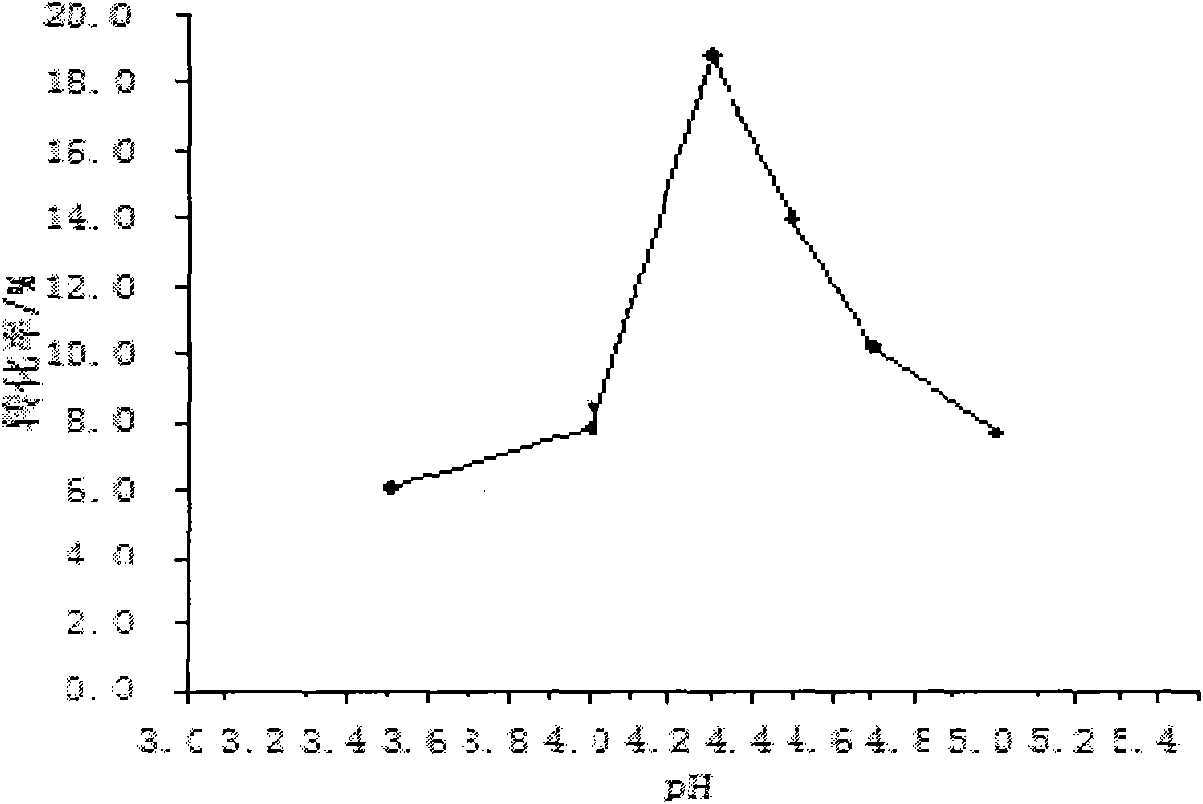

[0021] After the CGMCC No.3562E.coli ZS-07 strain was activated on the slant medium, it was transferred to the seed medium with a pH of 7.0-7.8. After shaking and culturing at 37°C for 6-9 hours, it was inoculated with an inoculum of 3-12%. Fermentation medium, pH 7.0-7.8, 37°C, 220r / min, shake culture for 8-14h, then reduce the pH to 3.5-3.8 0.5-1h before the end to obtain the fermentation broth containing bacteria, centrifuge and collect at 4000r / min bacteria. Resuspend the bacteria in water equivalent to 1 / 2 times the volume of the original fermentation broth, add 15g of L-glutamic acid to each 100mL of the bacterial suspension, add 0.1mmol / L of pyridoxal phosphate, and control the pH with hydrochloric acid or sulfuric acid. 3.5-3.8, shaking reaction at 41°C, when there is no insoluble substrate, add substrate L-glutamic acid 15g / 100mL. When reacting for about 20 hours, add pyridoxal phosphate 0.1mmol / L, then add substrate L-glutamic acid 15g / 100mL, and add bacteria (prepa...

Embodiment 2

[0023] After the CGMCC No.3562E.coli ZS-07 bacterial strain is activated on the slant medium, it is transferred to the seed medium, and after shaking and culturing at 37°C for 6-9h, it is inoculated with a 3-12% inoculum amount to contain pyridoxal phosphate ( 0.02mmol / L) fermentation medium, pH 7.0-7.8, 37°C shaking culture for 8-14h, reduce the pH to 3.5-3.8 0.5-1h before the end of the culture, add 28g L-glutamic acid per 100mL fermentation broth , use hydrochloric acid or sulfuric acid to control the pH to 3.5-3.8, continue to vibrate or stir until the substrate is completely converted, and centrifuge to obtain a reaction solution containing γ-aminobutyric acid, and the conversion rate can reach 100%.

Embodiment 3

[0025] After the CGMCC No.3562E.coli ZS-07 strain was activated on the slant medium, it was transferred to the seed medium with a pH of 7.0-7.8. After shaking and culturing at 37°C for 6-9 hours, it was inoculated with an inoculum of 3-12%. Fermentation medium, pH 7.0-7.8, 37°C, 220r / min, shake culture for 8-14h, then reduce the pH to 3.5-3.8 0.5-1h before the end of culture, obtain the fermentation broth containing bacteria, centrifuge at 4000r / min Separate and collect bacteria. Resuspend the bacteria in an acetic acid-sodium acetate buffer solution with a pH of 3.5 equivalent to 1 / 2 the volume of the original fermentation broth, add 5 g of L-sodium glutamate per 100 mL of the bacterial suspension, and control the pH to 3.5 with hydrochloric acid or sulfuric acid -3.8, shake the reaction at 41°C until the substrate is completely converted, centrifuge to obtain a reaction solution containing γ-aminobutyric acid, and the conversion rate reaches 100%. The purity of GABA reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com