Xiao er Anfen Huang Namin granule and preparation method thereof

A technology of children's paracetamol huangnamin granules and chlorpheniramine acid, which can be applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, and devices that make medicines into special physical or ingestible forms, and can solve the problem of children's drug use. Difficulty, large content fluctuations, uneven content and other problems, to achieve stable and controllable product quality, easy to control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

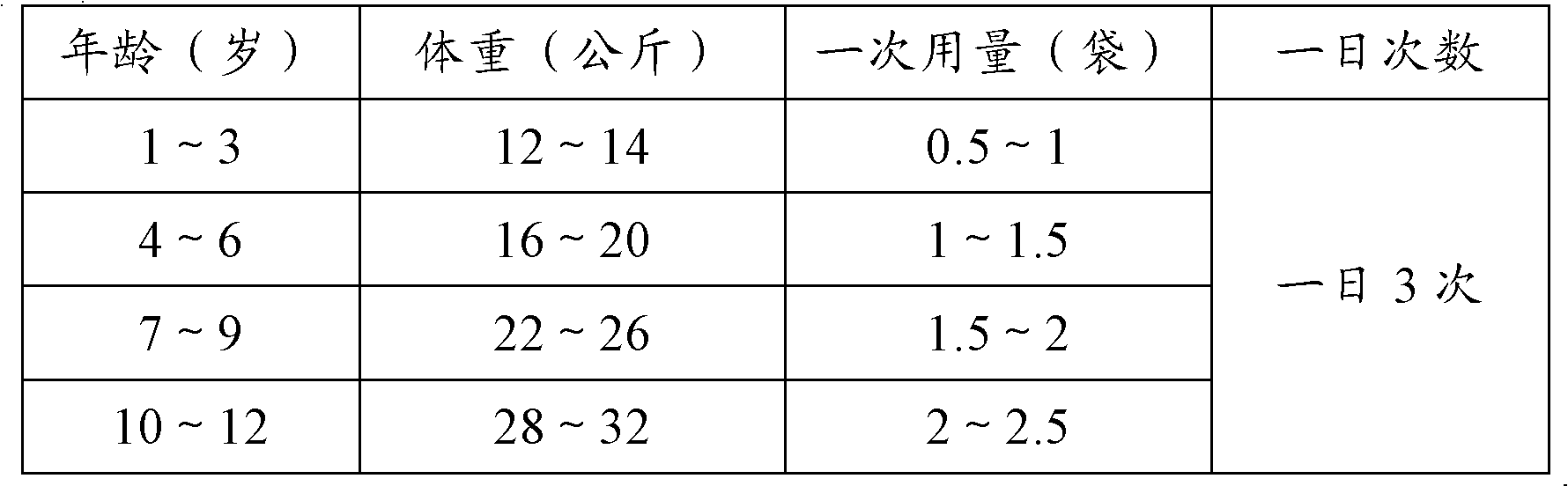

Image

Examples

Embodiment 1

[0034] Prescription 1:

[0035] Paracetamol 125g, chlorpheniramine maleate 0.5g, artificial bezoar 5g, sucrose powder 4870g, sodium carboxymethyl cellulose 4g, proper amount of flavor and proper amount of ethanol.

[0036] Dissolve 4 g of the above-mentioned binder into 262.67 g of purified water, stir and dissolve to prepare an aqueous solution of sodium carboxymethyl cellulose with a CMC-Na concentration of 1.5% by mass.

[0037] Preparation:

[0038] (1) Mix 125 g of paracetamol and 5 g of artificial bezoar fully to obtain the first mixture for use;

[0039] (2) Add 4870 g of sucrose powder to the first mixture prepared in step (1) in two times, each time adding 2435 g, and mixing after each addition to obtain the second mixture for use;

[0040] (3) Dissolve 0.5 g of chlorpheniramine maleate in 0.5 g of ethanol to prepare chlorpheniramine maleate ethanol solution, and add 1.5% (mass percentage concentration) to the chlorpheniramine maleate ethanol solution. ) Aqueous sodium carboxym...

Embodiment 2

[0042] Prescription 2

[0043] Acetaminophen 250g, chlorpheniramine maleate 1g, artificial bezoar 10g, lactose 5000g, povidone K303g, proper amount of flavor and proper amount of ethanol.

[0044] Dissolve 3 g of povidone K30 of the above-mentioned binder into 97 g of purified water, stir and dissolve to prepare an aqueous solution of povidone K30 with a concentration of 3% by mass.

[0045] Preparation:

[0046] (1) Fully mix 250 g of paracetamol and 10 g of artificial bezoar to obtain the first mixture for use;

[0047] (2) Add 5000 g of lactose into the first mixture prepared in step (1) in 2 times, each time the addition amount is 2500 g, after each addition, it needs to be mixed and evenly mixed to obtain the second mixture for use;

[0048] (3) Dissolve 1 g of chlorpheniramine maleate in 1.5 g of ethanol to prepare an ethanol solution of chlorpheniramine maleate, and add 3% povidone K30 aqueous solution to the ethanol solution of chlorpheniramine maleate. After mixing, it is mixed...

Embodiment 3

[0049] Prescription 3

[0050] 375g of acetaminophen, 1.5g of chlorpheniramine maleate, 15g of artificial bezoar, 5200g of sucrose, 6g of sodium carboxymethylcellulose, proper amount of flavor and proper amount of ethanol.

[0051] Dissolve 6 g of the above-mentioned binder into 394 g of purified water, stir and dissolve to prepare an aqueous solution of sodium carboxymethyl cellulose with a CMC-Na concentration of 1.5% by mass.

[0052] Preparation

[0053] (1) Mix 375 g of acetaminophen and 15 g of artificial bezoar fully to obtain the first mixture for use;

[0054] (2) Add 5200 g of sucrose to the first mixture prepared in step (1) in 2 times, each time the addition amount is 2600 g, after each addition, it needs to be mixed and evenly mixed to obtain the second mixture for use;

[0055] (3) Dissolve 1.5 g of chlorpheniramine maleate in 4.5 g of ethanol to prepare chlorpheniramine maleate ethanol solution, and add 1.5% carboxymethyl cellulose to the chlorpheniramine maleate ethanol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com