Deaminizing agent and preparation method thereof

A technology for removing ammonia and adhesives, applied in chemical instruments and methods, other chemical processes, silicates, etc., can solve the problems of low ammonia capacity, unfavorable long-term repeated use, easy loss of adsorption components, etc., and achieve ammonia capacity Enhancement, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 100g of the original NaZSM-5 molecular sieve powder, and put it into 1000mL of 0.2mol / L NH 4 NO 3 Exchange the solution at 60°C for 10 hours, take it out, filter, wash with water, and dry in an oven at 120°C for 6 hours; then mix with 70g silica sol (containing SiO 2 20%) kneaded and extruded into a strip, dried in an oven at 110°C for 15 hours, and calcined in a muffle furnace at 500°C for 10 hours to obtain a deamination / amine agent A.

Embodiment 2

[0024] Weigh 100g of powdered stilbite and put in 500mL of NH with a concentration of 1.0mol / L 4 Exchange the Cl solution at 30°C for 25 hours, take it out, filter, wash with water, and dry it in an oven at 100°C for 16 hours; then mix with 150g sodium silicate aqueous solution (containing SiO 2 28%) kneaded and extruded into a strip, dried in an oven at 110°C for 20 hours, and calcined in a muffle furnace at 600°C for 5 hours to obtain a deamination / amine agent B.

Embodiment 3

[0026] Weigh 100g of NaY molecular sieve powder, and put it in 1000mL of NH with a concentration of 0.5mol / L 4 NO 3 The solution was exchanged at 70°C for 10 hours, filtered, washed with water, dried in an oven at 80°C for 16 hours; then mixed with 42g of clay and extruded into a shape, dried in an oven at 140°C for 5 hours, and then dried in a muffle furnace in a hollow atmosphere. A deamination / amine agent C can be obtained by calcining at 500°C for 10 hours.

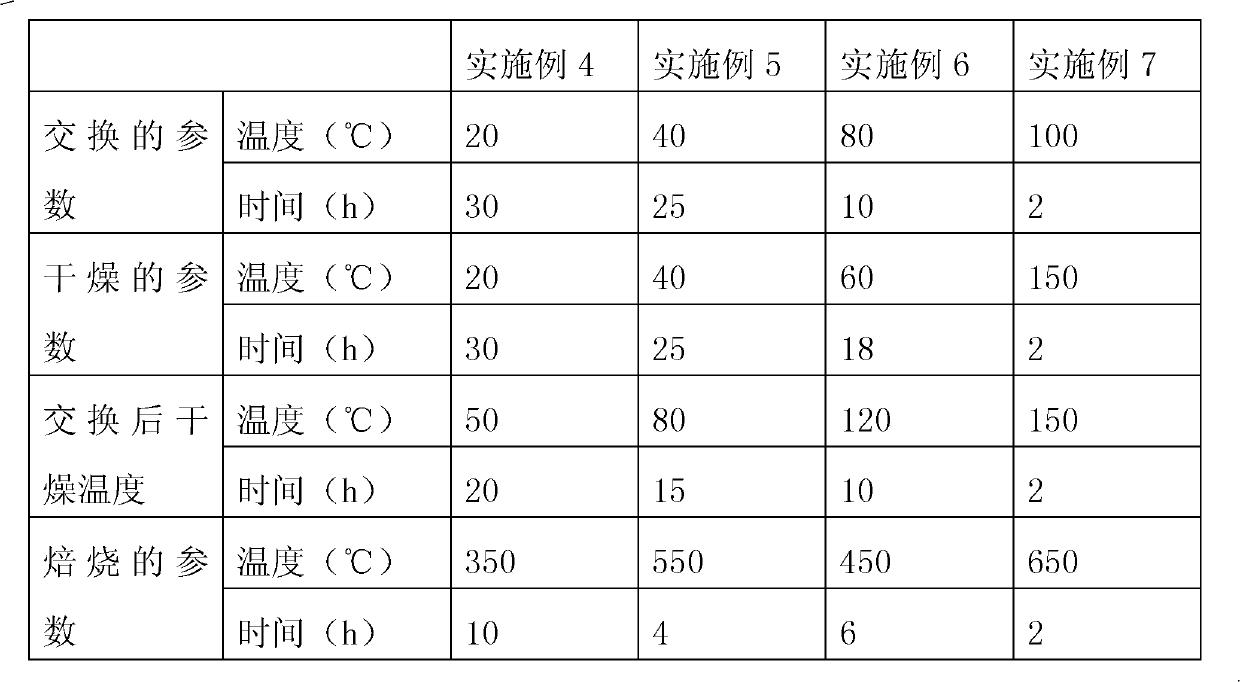

[0027] The same raw materials as in Example 3 were used to prepare the deamination / amine agent. Examples 4-7 with different other parameters are shown in Table 1 below.

[0028] Table 1

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com