Method for increasing room-temperature magnetic entropy change of amorphous soft magnetic alloy

A technology of soft magnetic alloy and amorphous alloy, which is applied in the field of magnetic refrigeration, can solve the problems of low magnetocaloric effect of amorphous alloy and cannot meet the needs of the development of magnetic refrigeration technology, and achieve the effect of increasing magnetic entropy change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

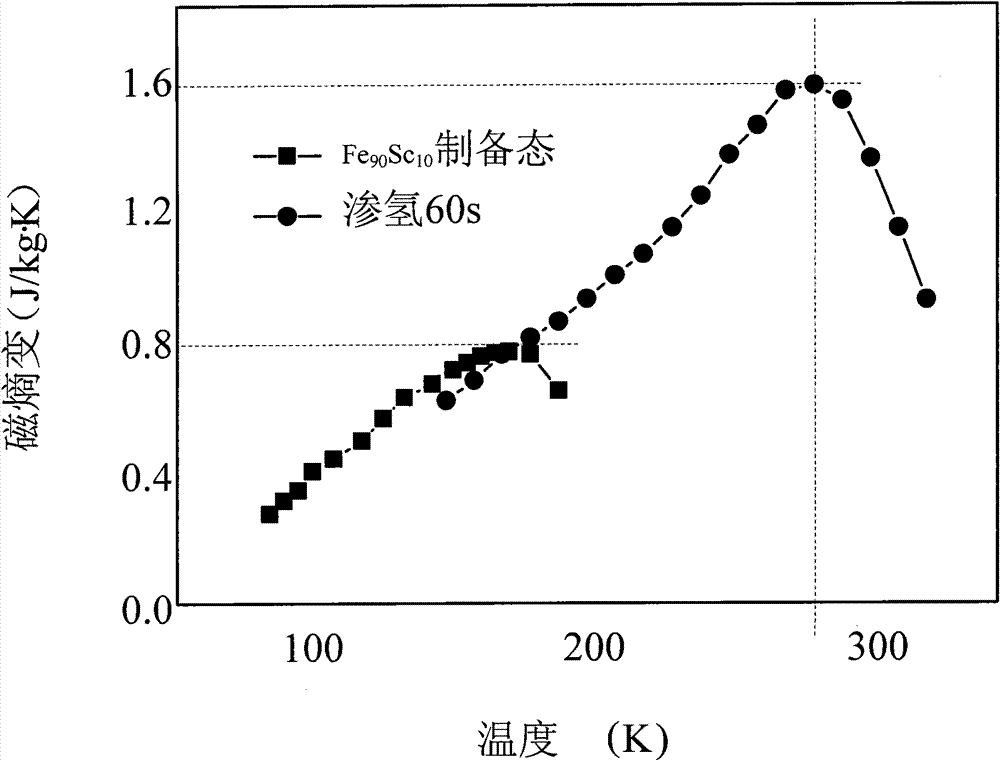

[0032] Example 1: Prepare 20μm thick, 1mm wide Fe 90 sc 10 Amorphous soft magnetic strips, and then the alloy is subjected to hydrogen permeation treatment by chemical electrolysis;

[0033] first step:

[0034] Press Fe 90 sc 10 The atomic percentage weighs iron Fe with a purity of 99.99wt.%, and Sc with a purity of 99.5wt.%.

[0035] The second step: alloy melting;

[0036] Put the raw materials prepared in the first step into the high vacuum arc melting furnace, and evacuate to 5×10 -4 Pa, melted with a heating current of 200A under the protection of high-purity argon to make ingots;

[0037] Then press the ingot into small pieces, put the block into 95% volume concentration of acetone solution for ultrasonic cleaning for 20 minutes, then perform ultrasonic surface cleaning in 99% volume concentration of alcohol solution for 10 minutes, take it out and dry it to obtain a dry block Body, ready for use;

[0038] The drying temperature is 30°C, and the drying time is...

Embodiment 2

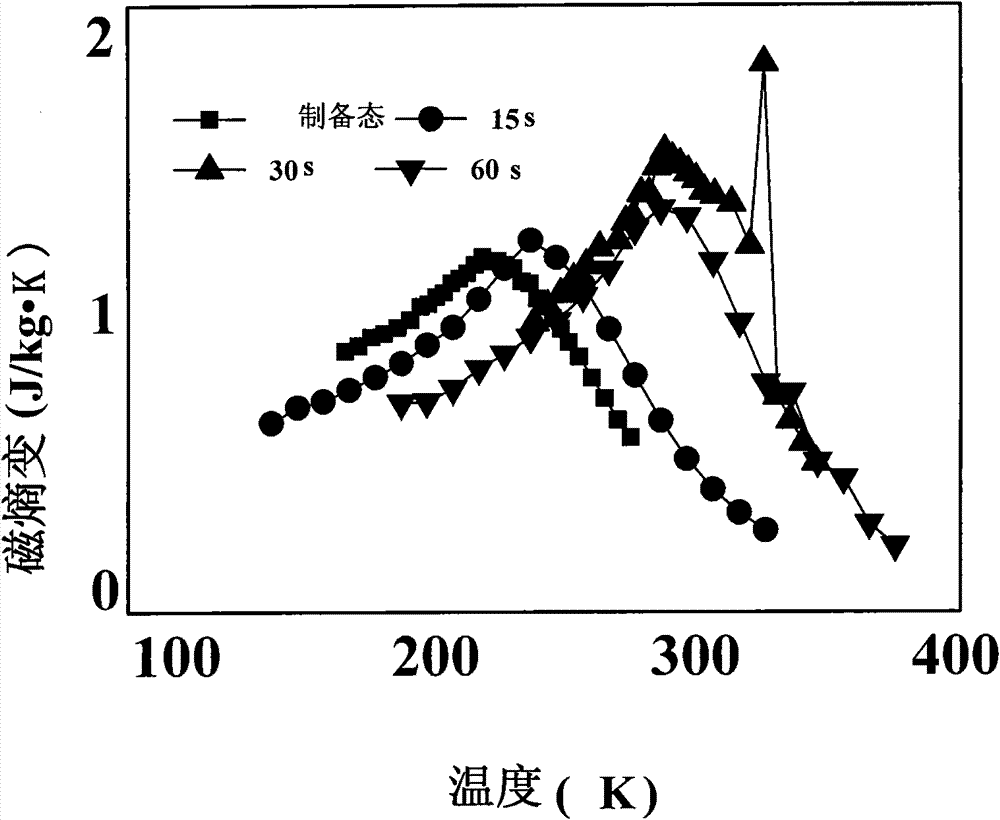

[0044] Example 2: Prepare 20μm thick, 1mm wide Fe 90 Zr 10 Amorphous soft magnetic strips, and then the alloy is subjected to hydrogen permeation treatment by chemical electrolysis. The specific steps are as follows:

[0045] Step 1: Press Fe 90 Zr 10 Atomic percentage weighs iron Fe with a purity of 99.99wt.%, and zirconium Zr with a purity of 99.5wt.%.

[0046] The second step: alloy melting;

[0047] Put the raw materials prepared in the first step into the high vacuum arc melting furnace, and evacuate to 5×10 -4 Pa, melted with a heating current of 220A under the protection of high-purity argon to make ingots;

[0048] Then the ingot is pressed into small pieces, and the block is put into a 95% acetone solution for ultrasonic cleaning for 5 minutes, and then ultrasonically cleaned for 25 minutes in a 99% alcohol solution, and then taken out and dried to obtain a dry block. stand-by;

[0049] The drying temperature is 50°C, and the drying time is 45 minutes;

[00...

Embodiment 3

[0056] Utilize method provided by the invention to improve amorphous alloy Fe 88 Zr 12 The room temperature magnetic entropy change.

[0057] Step one, press Fe 88 Zr 12 Atomic percentage weighs iron Fe with a purity of 99.99wt.%, and zirconium Zr with a purity of 99.5wt.%.

[0058] The second step: alloy melting;

[0059] The raw materials prepared in the first step are melted into ingots in a high-vacuum arc melting furnace, and after cleaning, they are taken out and dried to obtain dry blocks for use;

[0060] Drying temperature 40-50 ℃, drying time 40-45min;

[0061] The third step: swing belt;

[0062] Put the dry block obtained in the second step into the quartz tube of the single-roller stripping machine, and adjust the rotation speed of the single-roller to 65m / s to obtain an amorphous strip.

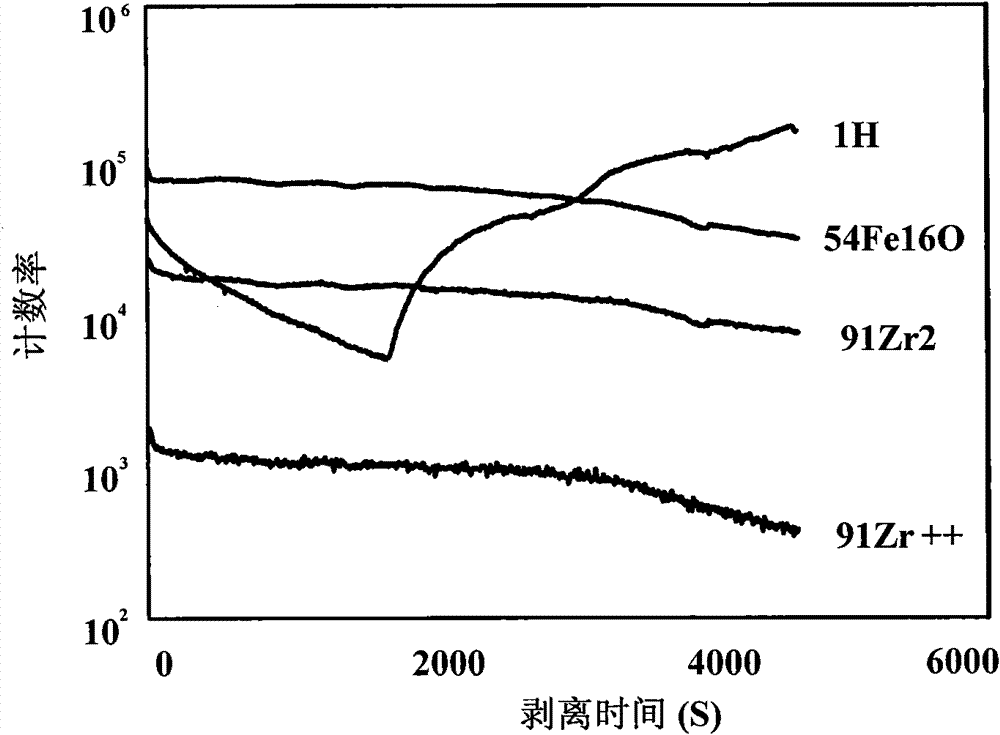

[0063] The fourth step: electrolytic hydrogen permeation;

[0064] The amorphous strip is subjected to hydrogen permeation treatment by chemical electrolysis method. Wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com