A kind of ni-co-mn-in alloy magnetic refrigeration material and preparation method thereof

A ni-co-mn-in, magnetic refrigeration material technology, applied in the direction of magnetic material, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc. Limiting the degree of performance and other issues, to achieve the effect of increasing the magnetic entropy change, increasing the magnetocaloric effect, and increasing the saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

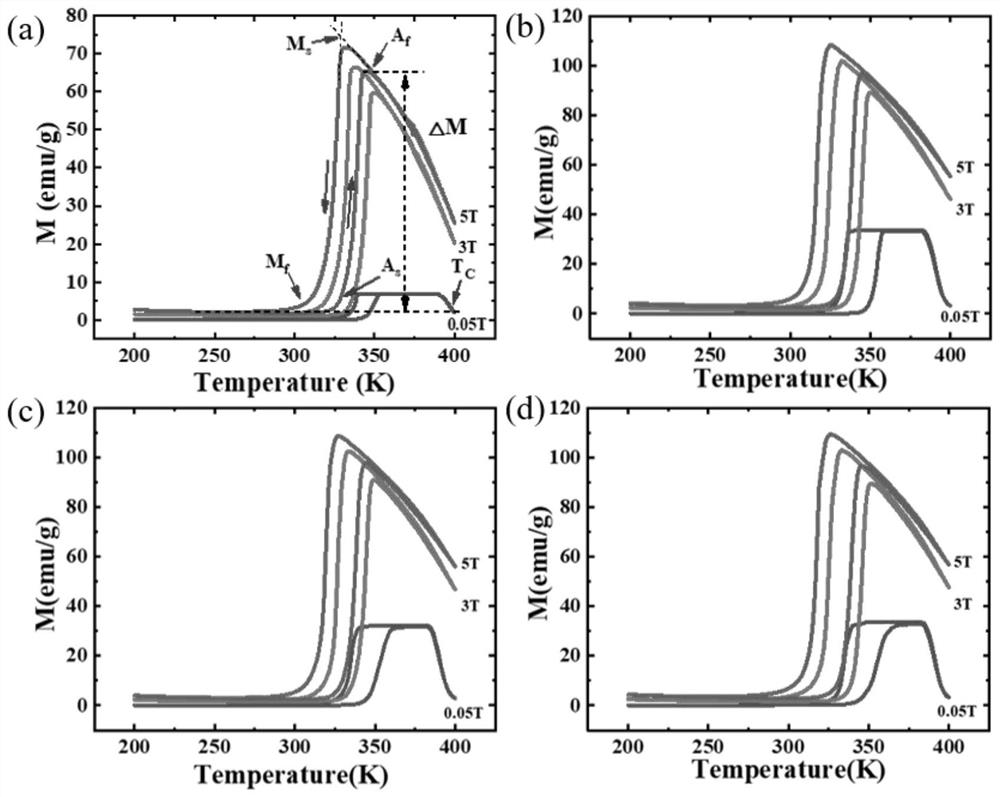

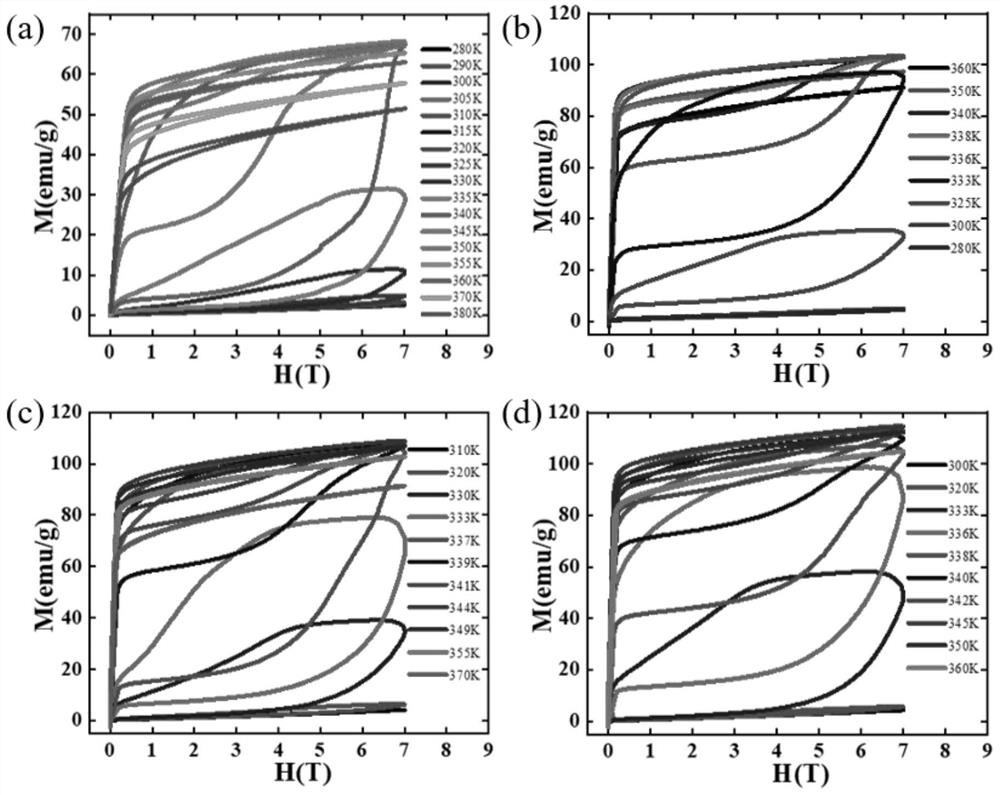

[0024] The invention provides a method for preparing a Ni-Co-Mn-In alloy magnetic refrigeration material, comprising the following steps:

[0025] The Ni-Co-Mn-In alloy ingot is subjected to solid solution annealing treatment, quenched into ice water, and the obtained alloy sample is subjected to electron irradiation treatment to obtain a Ni-Co-Mn-In alloy magnetic refrigeration material.

[0026] In the present invention, unless otherwise specified, the required raw materials are commercially available products well known to those skilled in the art.

[0027] In the invention, the Ni-Co-Mn-In alloy ingot is subjected to solution annealing treatment. In the present invention, the preparation process of the Ni-Co-Mn-In alloy ingot preferably includes: mixing raw materials corresponding to the Ni-Co-Mn-In alloy and melting to obtain an ingot. In the present invention, before the smelting, the raw material corresponding to the Ni-Co-Mn-In alloy is preferably subjected to mechani...

Embodiment 1

[0037] The alloy used in this embodiment consists of: Ni 45 co 5 mn 37 In 13

[0038] Weigh each raw material according to the above alloy ratio, the purity is 99.99wt.% Ni (24.59497g), 99.95wt.% Mn (19.49650g), 99.99999wt.% In (13.89946g) and 99.999wt.% Co (2.74394g), above-mentioned raw material is carried out mechanical polishing respectively, then carries out ultrasonic cleaning 5 times in dehydrated alcohol, after each raw material is mixed, melts in water-cooled copper crucible magnetic levitation induction furnace (temperature is 2000 ℃, the time is 0.5h), obtain ingot;

[0039] Seal the ingot into a vacuum of 10 -4 In a Pa quartz tube, solution annealing was carried out at 900°C for 24 hours, and quenched into ice water to obtain alloy samples;

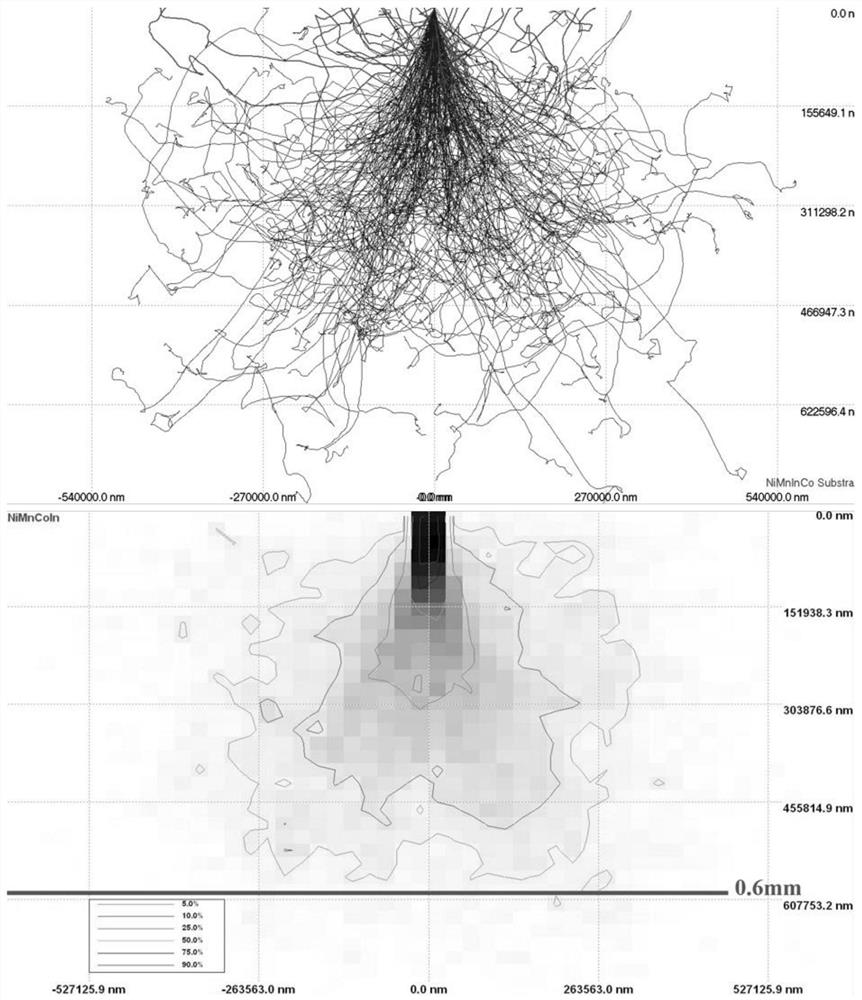

[0040] The alloy sample was wire-cut until the thickness was about 0.6mm, then mechanically polished, and the obtained sample was subjected to electron irradiation treatment, and the vacuum degree in the target chamber w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetocaloric effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com