Ni-Co-Mn-In alloy magnetic refrigeration material and preparation method thereof

A technology of ni-co-mn-in and magnetic refrigeration materials, applied in the fields of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc. Limiting performance and other issues, to achieve the effect of increasing magnetic entropy change, improving magnetocaloric effect, and increasing saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a Ni-Co-Mn-In alloy magnetic refrigeration material, comprising the following steps:

[0025] The Ni-Co-Mn-In alloy ingot is subjected to solid solution annealing treatment, quenched into ice water, and the obtained alloy sample is subjected to electron irradiation treatment to obtain a Ni-Co-Mn-In alloy magnetic refrigeration material.

[0026] In the present invention, unless otherwise specified, the required raw materials are commercially available products well known to those skilled in the art.

[0027] In the invention, the Ni-Co-Mn-In alloy ingot is subjected to solution annealing treatment. In the present invention, the preparation process of the Ni-Co-Mn-In alloy ingot preferably includes: mixing raw materials corresponding to the Ni-Co-Mn-In alloy and melting to obtain an ingot. In the present invention, before the smelting, the raw material corresponding to the Ni-Co-Mn-In alloy is preferably subjected to mechani...

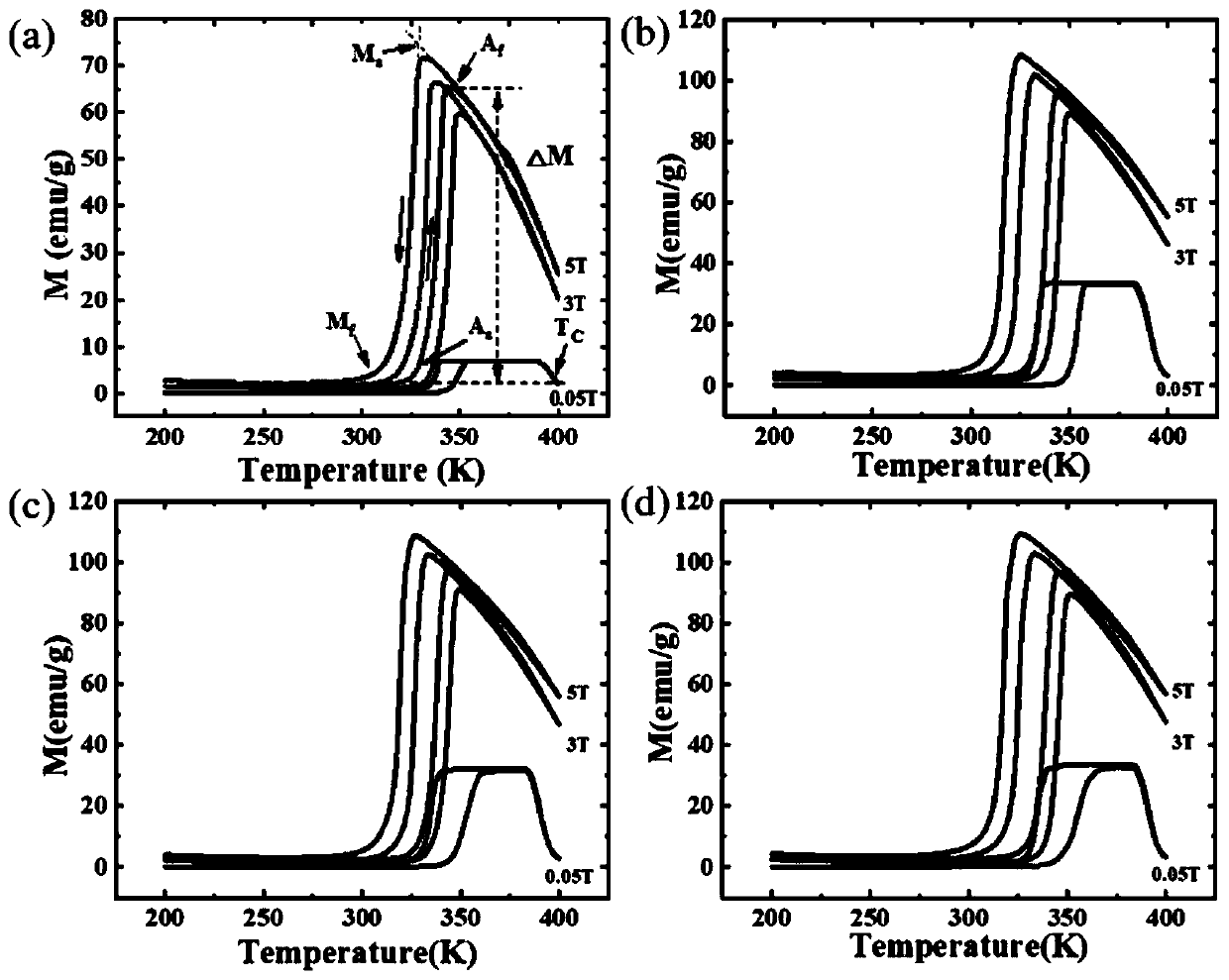

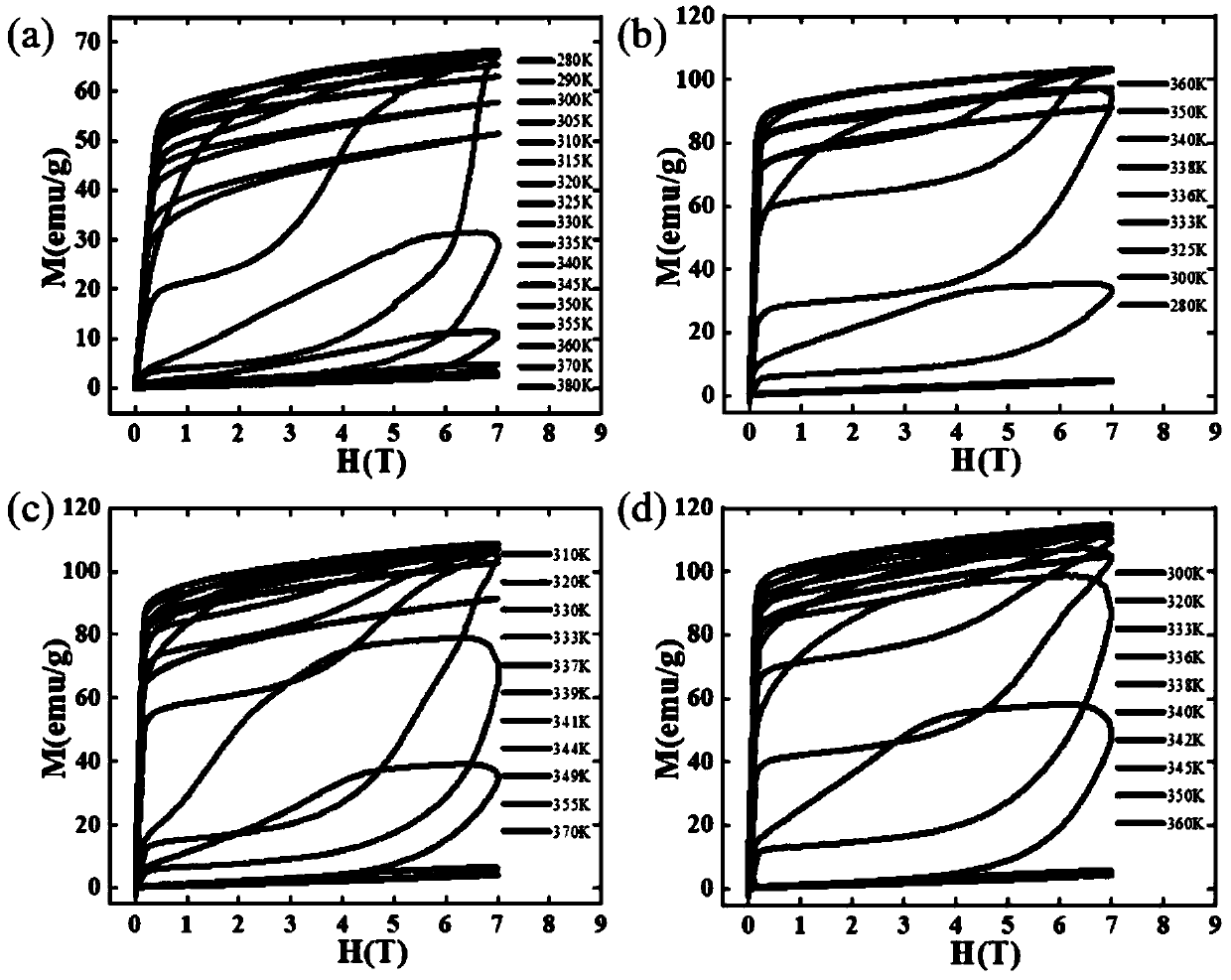

Embodiment 1

[0037] The alloy used in this embodiment consists of: Ni 45 co 5 mn 37 In 13

[0038] Weigh each raw material according to the above alloy ratio, the purity is 99.99wt.% Ni (24.59497g), 99.95wt.% Mn (19.49650g), 99.99999wt.% In (13.89946g) and 99.999wt.% Co (2.74394g), above-mentioned raw material is carried out mechanical polishing respectively, then carries out ultrasonic cleaning 5 times in dehydrated alcohol, after each raw material is mixed, melts in water-cooled copper crucible magnetic levitation induction furnace (temperature is 2000 ℃, the time is 0.5h), obtain ingot;

[0039] Seal the ingot into a vacuum of 10 -4 In a Pa quartz tube, solution annealing was carried out at 900°C for 24 hours, and quenched into ice water to obtain alloy samples;

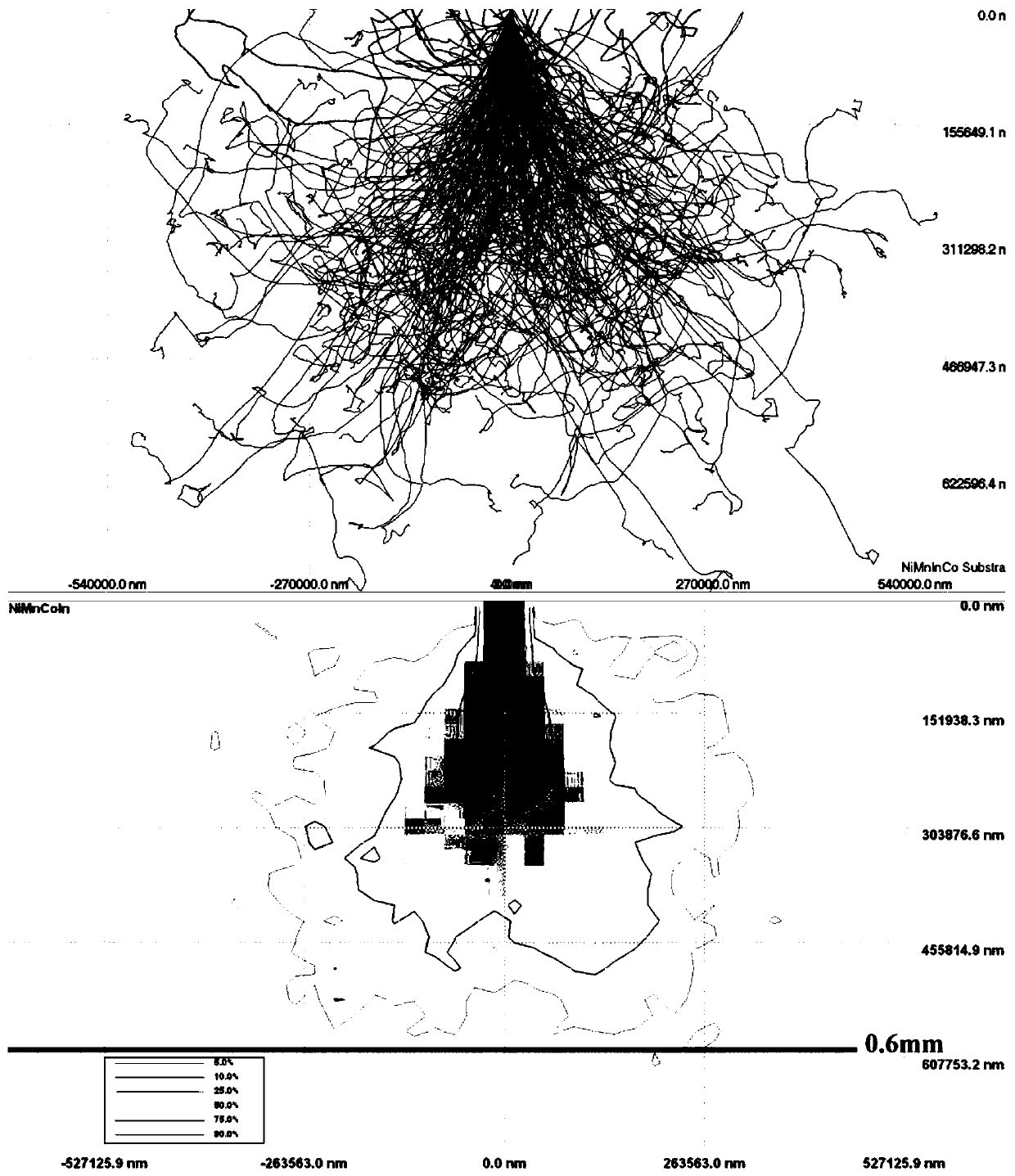

[0040] The alloy sample was wire-cut until the thickness was about 0.6mm, then mechanically polished, and the obtained sample was subjected to electron irradiation treatment, and the vacuum degree in the target chamber w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com