A hydrogenated heavy rare earth high-entropy composite material and its preparation method and application

A composite material and heavy rare earth technology, applied in the fields of magnetic materials, inorganic material magnetism, transportation and packaging, etc., can solve the problem of low magnetic entropy change of amorphous alloys, improve the magnetic entropy change, improve the ability to form amorphous, reduce Effect of Hysteresis Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

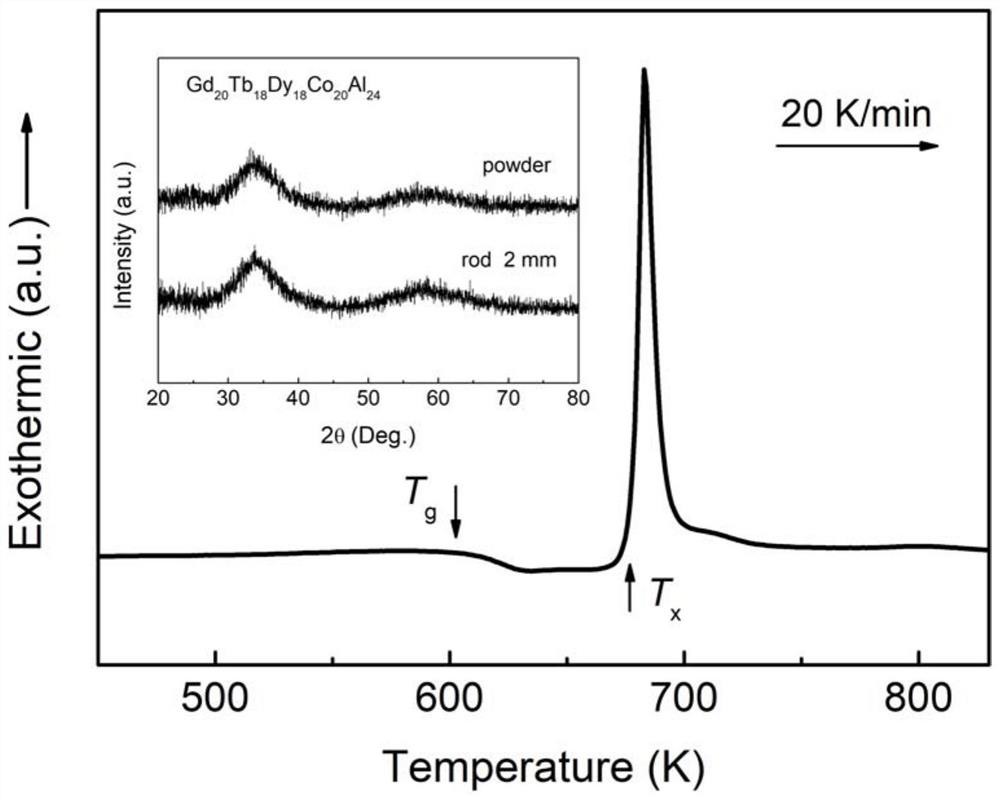

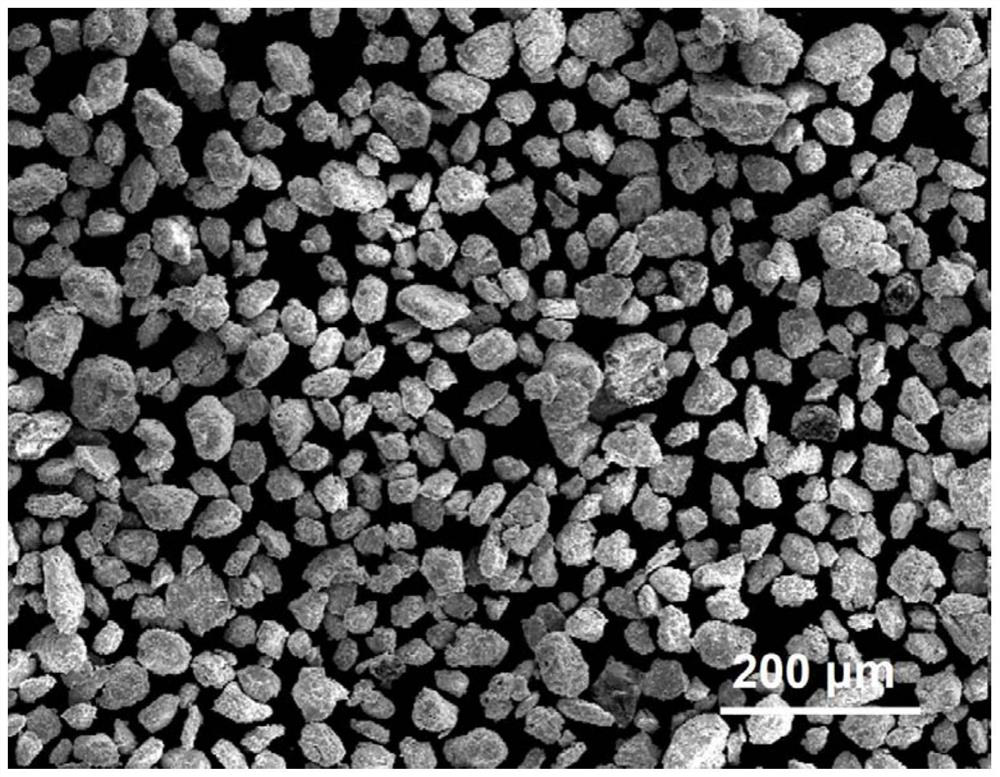

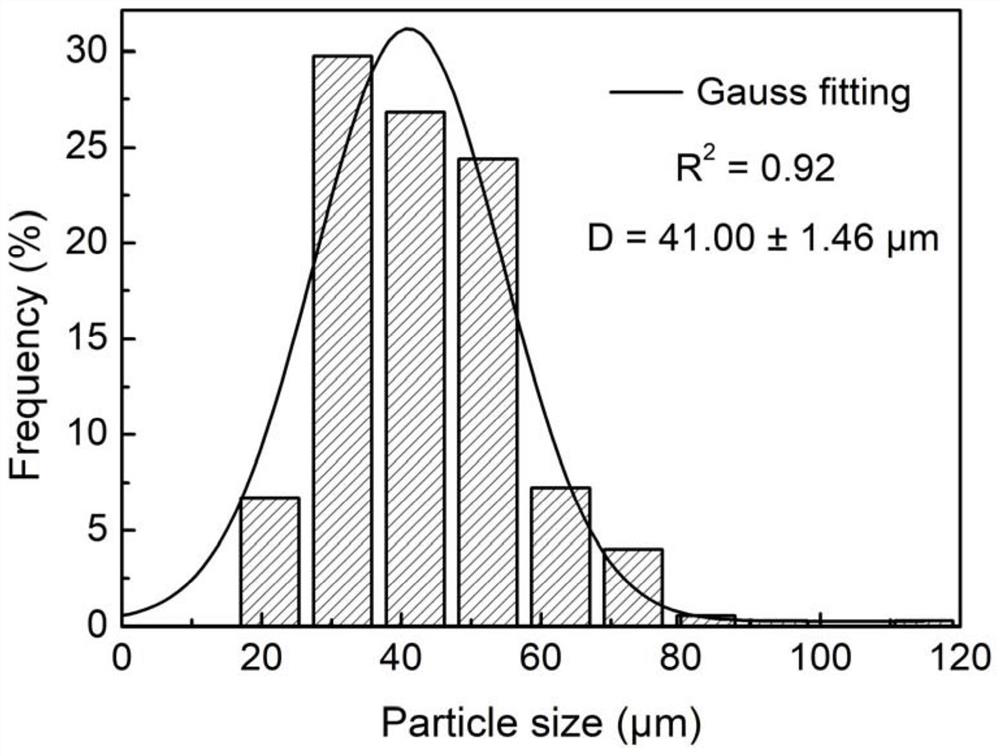

[0045] The chemical formula for preparation is Gd 20 Tb 18 Dy 18 co 20 al 24 h 130.65 heavy rare earth high-entropy composites.

[0046] The preparation process is as follows:

[0047] Step 1, the Gd, Tb, Dy, Co, Al raw materials with a purity greater than 99.9wt.% are formulated according to the molecular formula Gd 20 Tb 18 Dy 18 co 20 al 24 Indicated atomic percentage ingredients;

[0048] Step 2, put the raw materials weighed in step 1 in the water-cooled copper crucible of the electric arc melting furnace, close the cavity, and first evacuate the cavity to 3×10 -3 Below Pa, then fill it with high-purity argon protection for smelting. First, smelt the titanium ingot for 3-5 minutes to further remove the residual oxygen in the cavity, and then melt the alloy ingot twice with a low current (150-180A), and then use a high current (270-180A) to melt the alloy ingot twice. 300A) Melting the alloy ingot four times, flipping the alloy ingot before each smelting, and t...

Embodiment 2

[0066] Referring to Example 1, the preparation chemical molecular formula is Gd 20 Tb 18 Dy 18 co 20 al 24 h 43.2 heavy rare earth high-entropy composites.

[0067] The difference lies in step 5: under the protection of high-purity argon, place the high-entropy amorphous alloy powder prepared in step 4 in the hydrogen absorption device, set the hydrogen pressure in the cavity to 5MPa, heat the sample to 265°C and keep it warm for isothermal hydrogen absorption , The isothermal time is 12h. The mass fraction of inhaled hydrogen is 0.4%, after conversion into atomic percentage, the molecular formula of the obtained hydrogenated heavy rare earth high-entropy composite material is Gd 20 Tb 18 Dy 18 co 20 al 24 h 43.2 .

[0068] The XRD spectrum of the above-mentioned hydrogenated high-entropy amorphous alloy powder is as follows Figure 11 As shown, it can be seen that, similar to the sample obtained in Example 1, GdH was precipitated on the amorphous matrix after a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com