Quicklime coupling and digesting device

A quicklime and complete digestion technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as increased equipment investment, easy blockage of pipelines, and blockage of exhaust systems, so as to improve digestion efficiency and avoid knots. Dirt, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

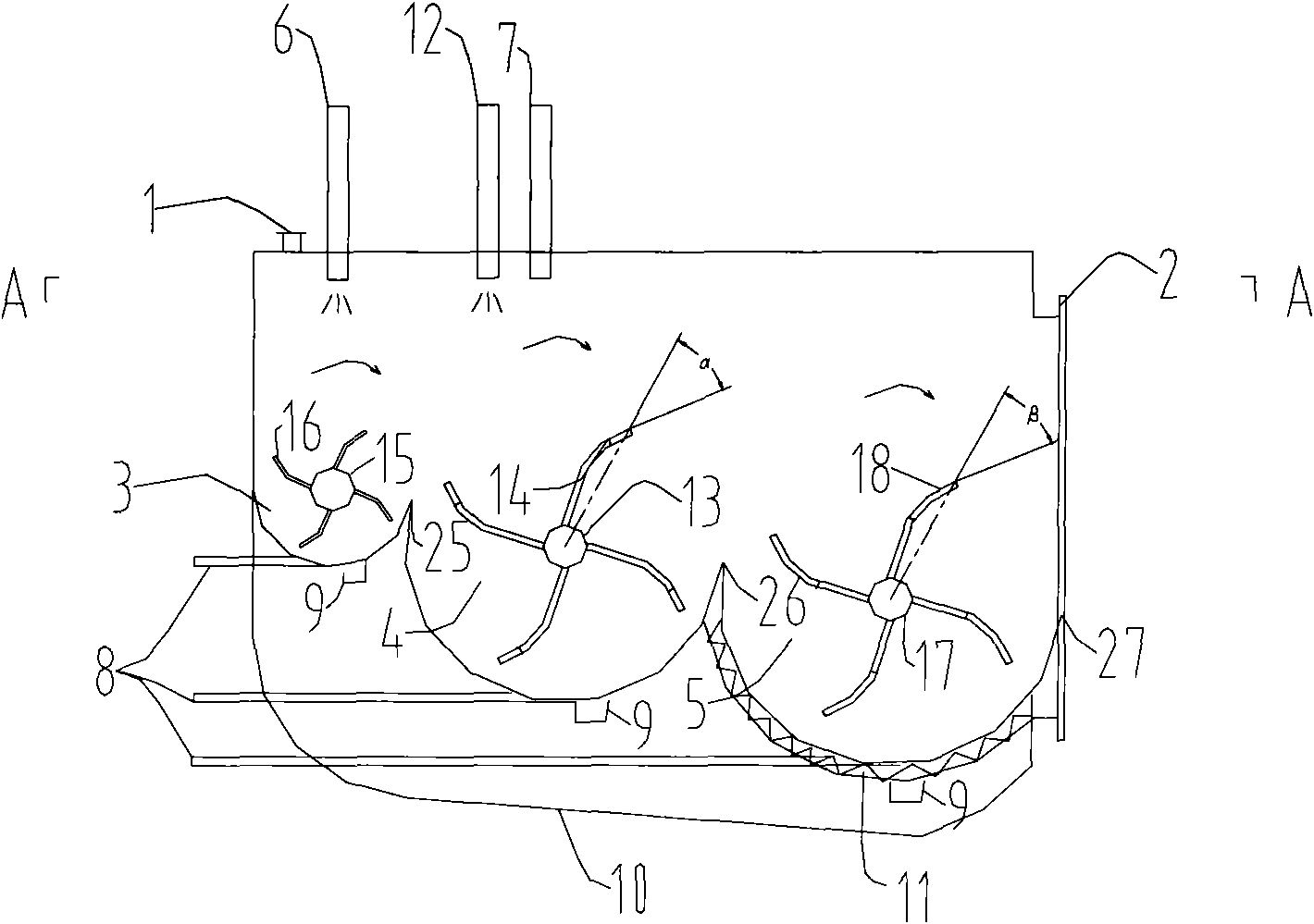

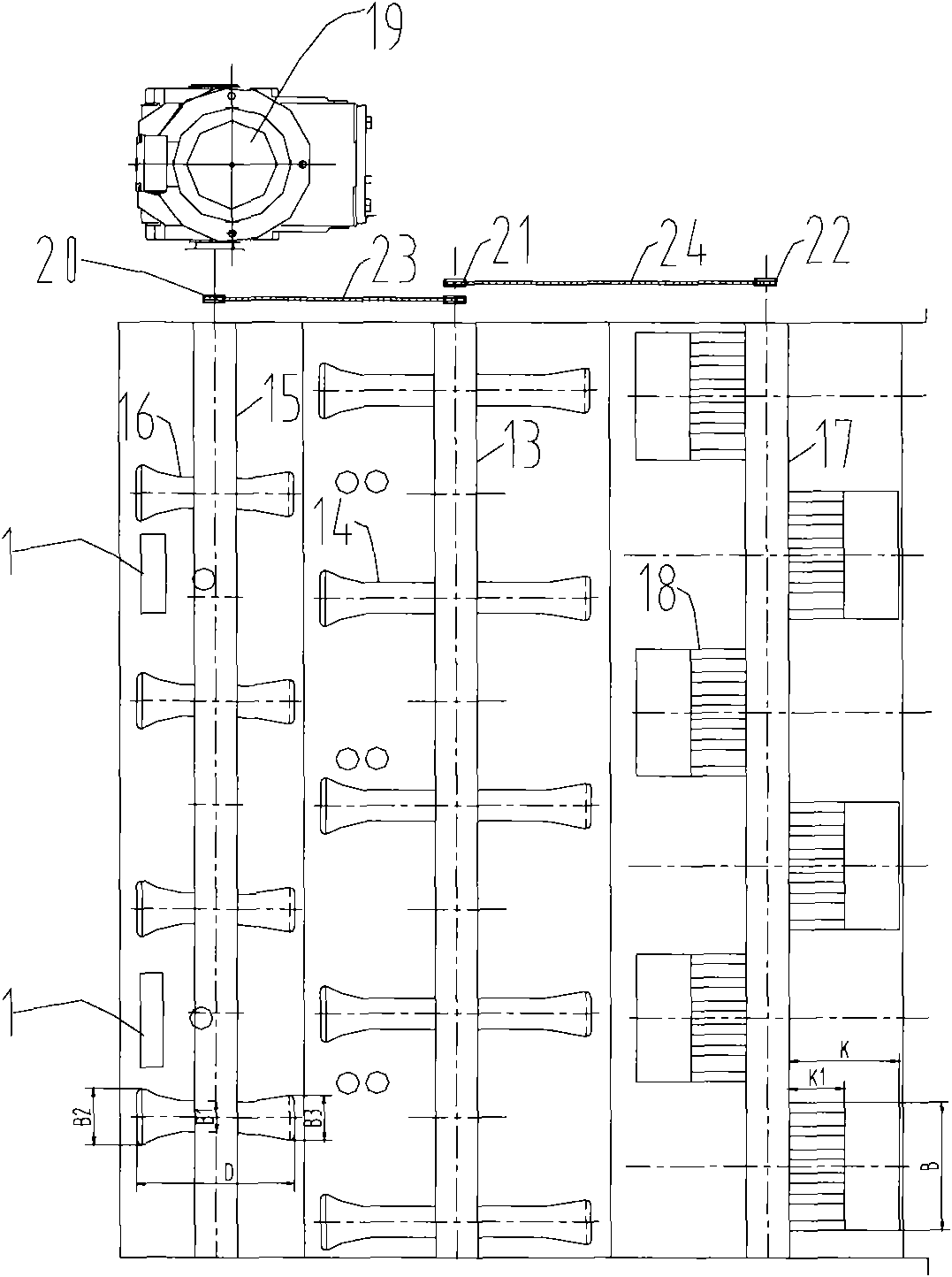

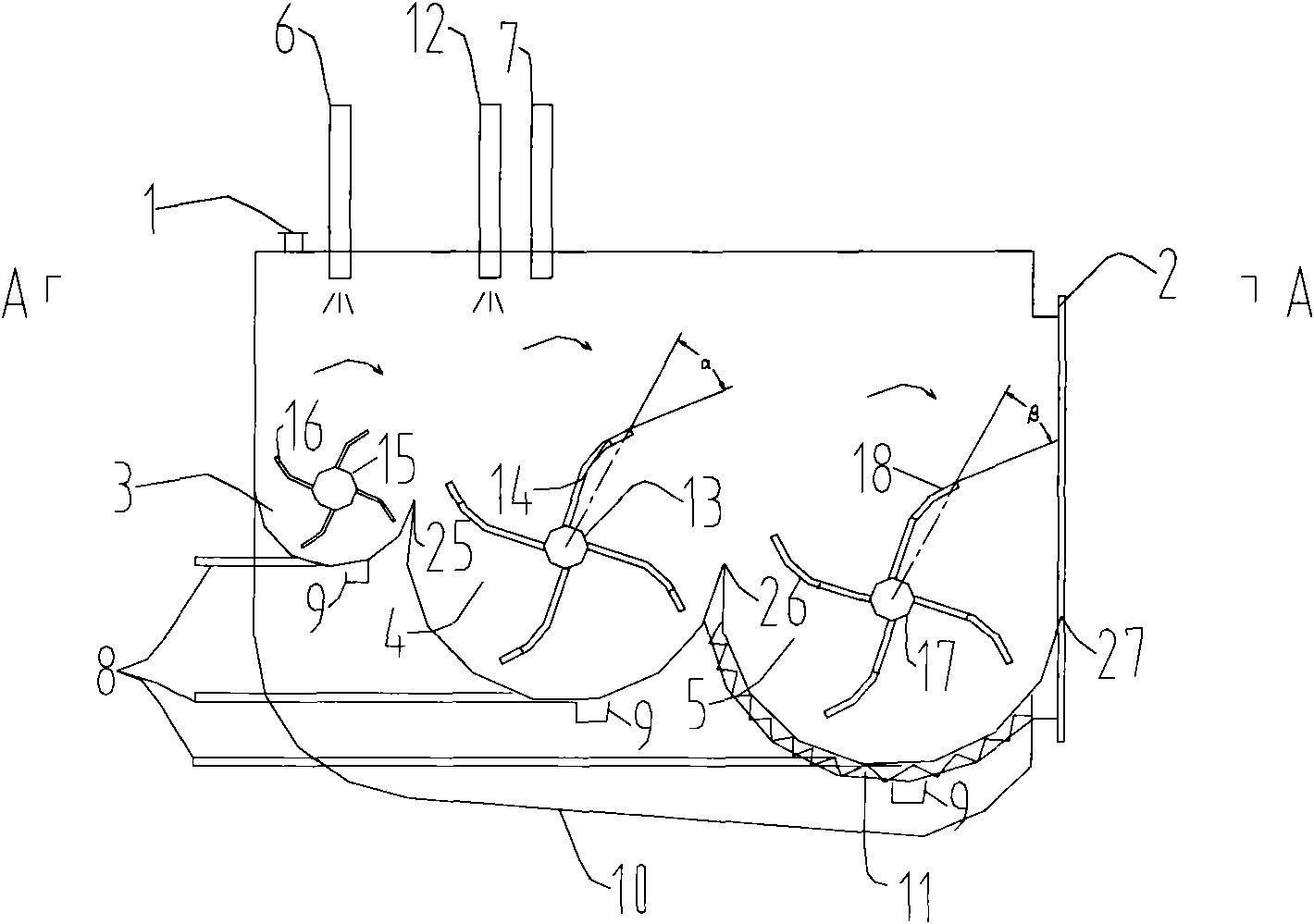

[0019] Such as figure 1 , 2 As shown, a quicklime coupling digestion device includes a frame 10, on which a primary coarse particle digestion zone 3, a secondary coupling digestion zone 4 and a complete digestion zone 5 are sequentially arranged, and the primary coarse particle digestion zone 3 is provided with at least one feeding port 1, and the rear part of the complete digestion zone 5 is provided with at least one discharge port 2, and a first water spray device 6 is provided above the primary coarse particle digestion zone 3, A second water spray device 12 and an additive device 7 are provided above the secondary coupling digestion zone 4, and the first stirring assembly, The second stirring assembly and the third stirring assembly are all connected to the driving device 19 . The first stirring assembly includes a first shaft 15 and several first impellers 16 distributed on the first shaft 15; the second stirring assembly includes a second shaft 13 and several second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com