Tilapia mossambica overwintering feed

A tilapia and feed technology, applied in the field of tilapia farming, can solve problems such as intolerance to low temperature and high temperature, achieve the effects of improving nutritional balance, improving disease resistance and anti-stress ability, and ensuring smooth wintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

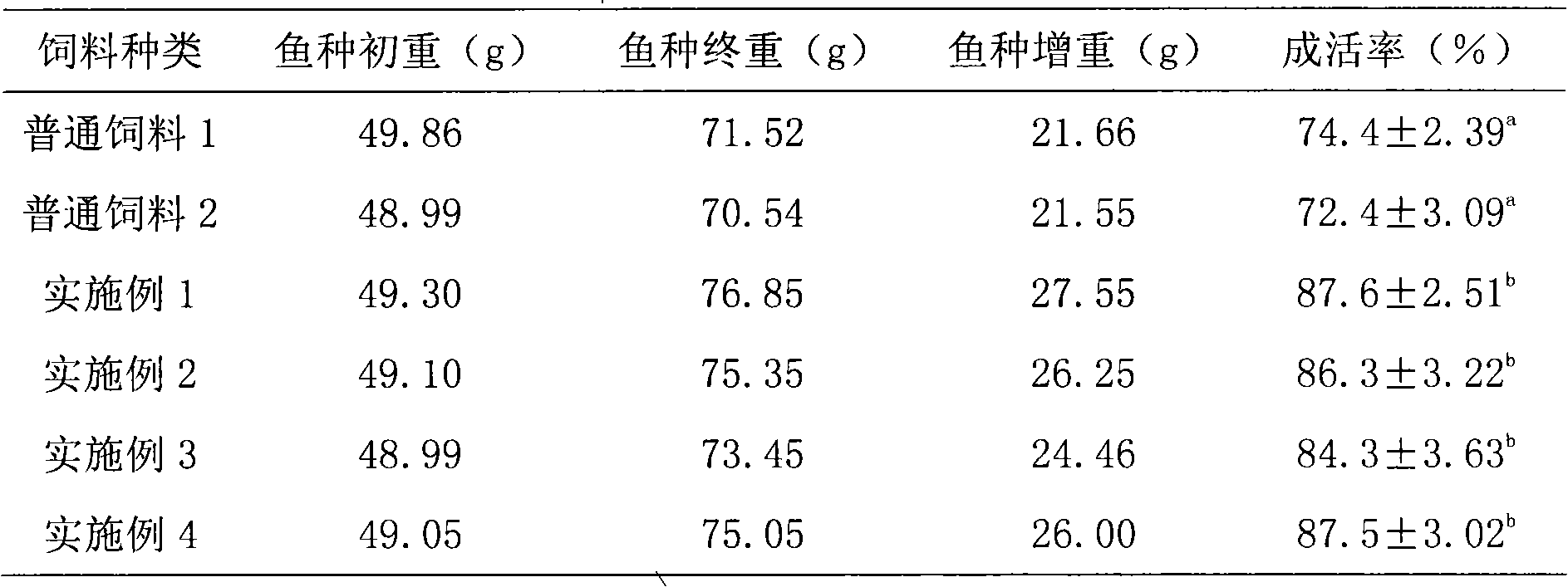

Examples

Embodiment 1

[0016] Tilapia overwintering feed, its basic formula is mainly the following raw materials by weight percentage:

[0017] Soybean Meal 20%

[0018] Fish Meal 5%

[0019] 20% rapeseed meal, 13% cottonseed meal, 2.5% rice bran meal

[0020] Wheat Flour 33%

[0021] Fish Oil 3.5%

[0022] Vitamin E 0.03%.

[0023] The remaining 2.97% are additives, including 1% premix, 1.67% calcium hydrogen phosphate and 0.3% table salt.

[0024] According to the above formula, adopt the following method to prepare tilapia overwintering feed: firstly crush soybean meal, fish meal, rapeseed meal, cottonseed meal and rice bran meal respectively, then take wheat flour and mix the crushed raw materials, then add fish oil, vitamin E and additives, etc. Further preparation and mixing, tempering and granulation are obtained.

[0025] The crude protein, crude fat, ash and moisture content of the obtained feed were determined to be 30%, 5%, 7.5% and 10% respectively.

Embodiment 2

[0027] Tilapia overwintering feed, its basic formula is mainly the following raw materials by weight percentage:

[0028] Soybean Meal 31%

[0029] Fish Meal 3%

[0030] 8% rapeseed meal, 7% rice bran meal, 8.5% peanut meal

[0031] Wheat Flour 35%

[0032] Fish Oil 2%

[0033] Vitamin E 0.04%

[0034] The remaining 5.46% is phospholipid feed (2.2%) and additives (3.26%), and additives include 1% premix, 1.96% calcium hydrogen phosphate and 0.3% salt.

[0035] The preparation method is the same as in Example 1.

[0036] The crude protein, crude fat, ash and moisture content of the obtained feed were determined to be 28.5%, 5%, 7% and 9.8%, respectively.

Embodiment 3

[0038] Tilapia overwintering feed, its basic formula is mainly the following raw materials by weight percentage:

[0039] soybean meal 25%

[0040] Fishmeal 2%

[0041] 17% rapeseed meal, 18% rice bran meal

[0042] Wheat Flour 28%

[0043] Fish Oil 5.0%

[0044] Vitamin E 0.04%

[0045] The remaining 4.96% is phospholipid feed (1.9%) and additives (3.06%), and additives include 1% premix, 1.76% calcium hydrogen phosphate and 0.3% salt.

[0046] The preparation method is the same as in Example 1.

[0047] The crude protein, crude fat, ash and moisture content of the obtained feed were determined to be 25%, 7%, 8% and 10.5% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com