Rubber compound modified asphalt and preparation method thereof

A technology of composite modified asphalt and rubber, which is applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of poor low temperature performance and easy softening, etc., and achieve the effect of improving product quality and enhancing construction workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preparation Examples:

[0021] Petroleum asphalt is transported through an asphalt pump, measured by a mass flow meter and heated to 170-180°C by a rapid heating heat exchange system; the heated asphalt, rubber powder and additives are measured in proportion and added to the mixer for stirring to mix and swell. Reaction time: 40 minutes. The ratio is: 39.3% of petroleum asphalt; 35% of rubber powder; 15% of coal tar; 5% of cement; 3% of dimethylaminopyridine (catalyst); .

[0022] Pump the mixture obtained in step b to the colloid mill for shearing and grinding; pump the sheared and ground mixture to the reaction storage tank for rapid re-swelling, then return to pumping to the colloid mill for shearing and grinding again to produce qualified rubber compound modified finished asphalt.

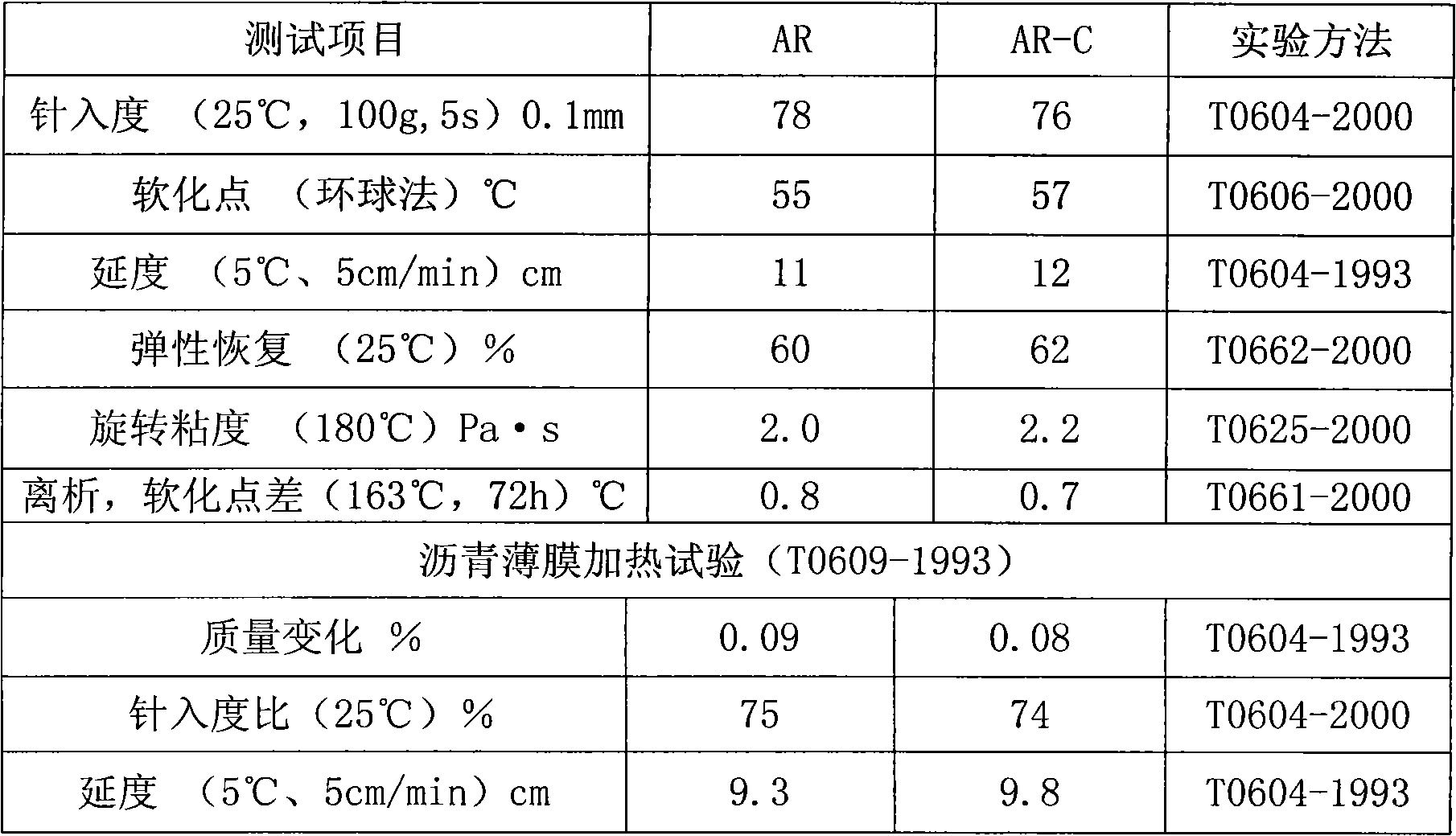

[0023] Performance characteristics of the finished product:

[0024] The invention has the characteristics of anti-rutting at high temperature, anti-cracking at low temperature, anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com