Pretreatment method for dehydrating, dedusting and retaining components to be detected in boiler smoke detection

A boiler flue gas and pretreatment technology, applied in the preparation of test samples, etc., can solve the problems of condensation and dissolution loss of instrument pipelines, easy to be blocked by dust, etc., and achieve the effects of not being easily damaged, avoiding dissolution loss, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Specific embodiments of the present invention can further supplement and illustrate the present invention, but are not limited to these embodiments.

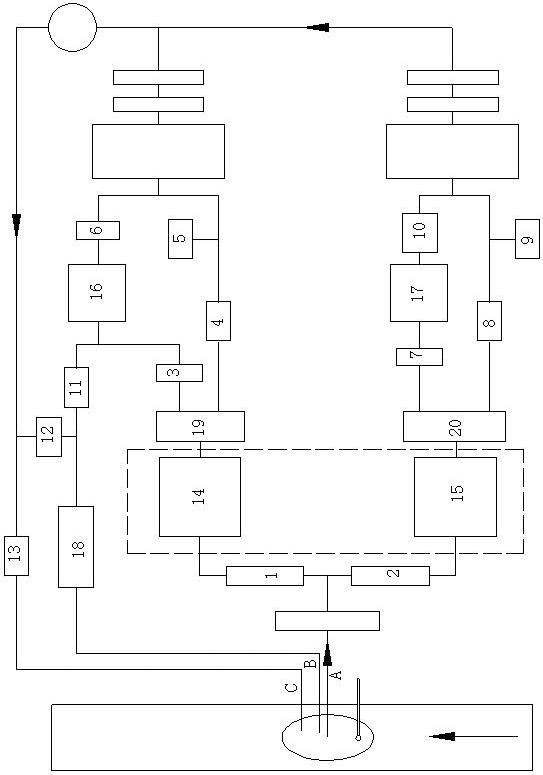

[0064] The invention provides a pretreatment method for dehydration, dust removal and retention of components to be tested during boiler flue gas detection. According to the properties of the flue gas to be detected, the method passes the flue gas into a corresponding buffer solution to remove components that are not compatible with the properties of the components to be detected. The opposite component absorbs water vapor and dust in the flue gas at the same time; the buffer solution is divided into a sulfur retention buffer solution and an ammonia retention buffer solution; the sulfur retention buffer solution is composed of concentrated sulfuric acid and sulfate saturated solution mixed solution; the ammonia-preserving buffer solution is a mixed solution of sodium hydroxide saturated solution and sodium sulfate saturate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com