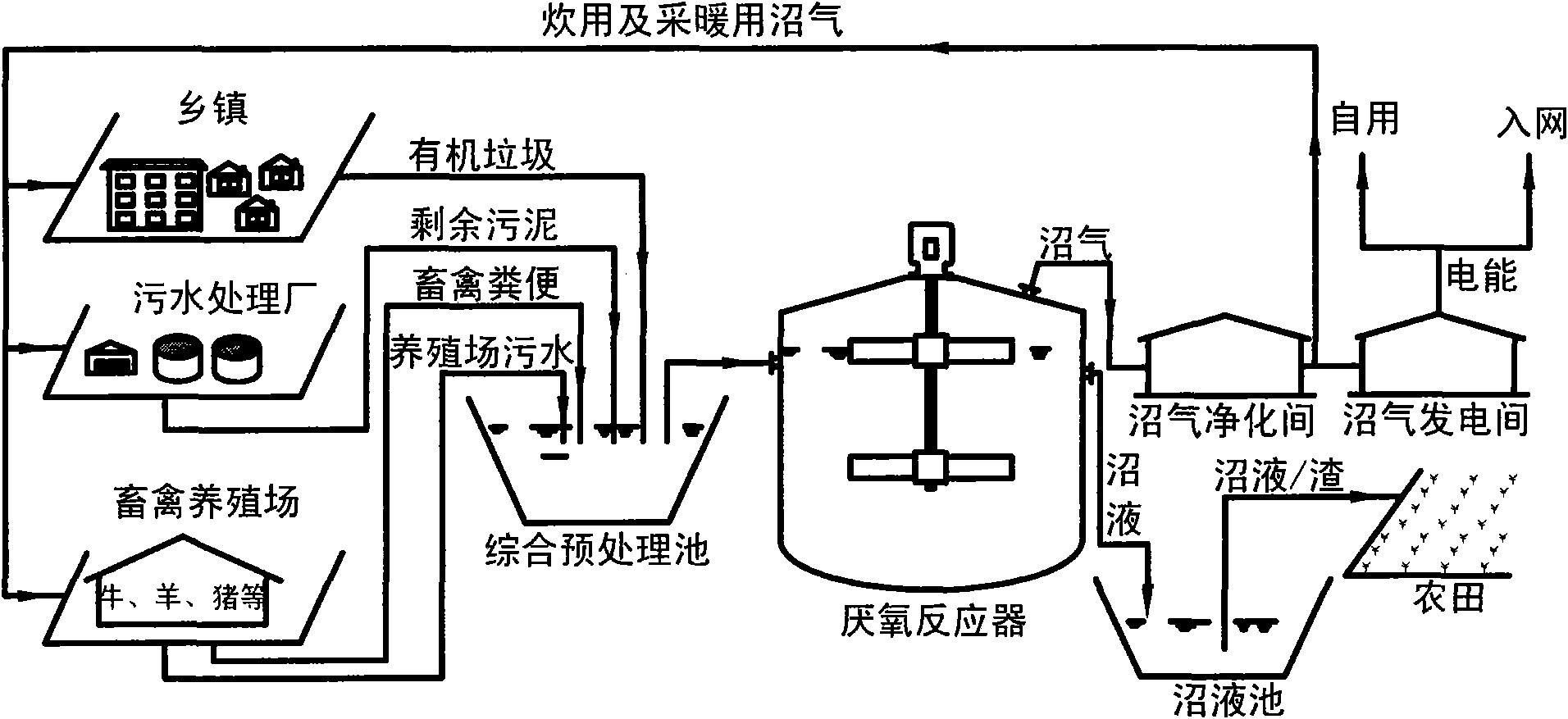

Method for producing biogas by garbage union fermentation

A combined fermentation and biogas technology, applied in fermentation, biological sludge treatment, sludge treatment, etc., can solve the problems of easy acidification and low gas production rate, and achieve the effect of avoiding acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Relying on a large-scale biogas project for livestock and poultry breeding, the volume of the main anaerobic reaction tank is 2000m 3 , the anaerobic digestion sludge in the sludge digestion anaerobic reactor of the urban sewage treatment plant is used as the inoculation sludge, and the inoculation sludge amount is 20% of the designed volume of the reactor. The mass ratio of organic waste, urban sewage treatment plant sludge, and livestock and poultry manure (cow dung) is designed in accordance with 1:3:3. The particle size of organic waste after crushing is less than 0.5cm. The concentration of solids in the feed is 10%, and the feeding method is intermittent feeding, 4 times a day, 15 minutes each time, and the daily feeding amount is 1 / 25 of the designed volume of the reactor. The amount of material is equivalent, the amount of material in the reactor accounts for 90% of the designed volume of the reactor, the hydraulic retention time of the material in the reactor ...

Embodiment 2

[0017] Design an anaerobic reactor with a volume of 20L. The anaerobic digestion sludge in the anaerobic reactor of the manure treatment biogas project of the livestock and poultry breeding plant is used as the inoculation sludge, and the amount of inoculation sludge is 20% of the designed volume of the reactor. The mass ratio of organic waste, urban sewage treatment plant sludge, and livestock and poultry manure (cow dung) is designed in accordance with 1:3:3. The particle size of organic waste after crushing is less than 0.1cm. The solids concentration in the feed was 12%, and the feeding method was intermittent feeding, once a day, 1 L each time. The amount of output is equivalent to the amount of feed, and the amount of material in the reactor accounts for 90% of the designed volume of the reactor. The pH of the material in the reactor is controlled between 6.9-7.2, and the reaction temperature is controlled at 35±1°C. After stable operation, the methane gas content in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com