Ultraviolet curing glue and preparation method thereof

A technology of curing glue and ultraviolet light, which is used in adhesives, non-polymer organic compound adhesives, polyurea/polyurethane adhesives, etc., can solve the problems of poor ultraviolet resistance and high brittleness, and achieve low production cost and low brittleness. , The effect of good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

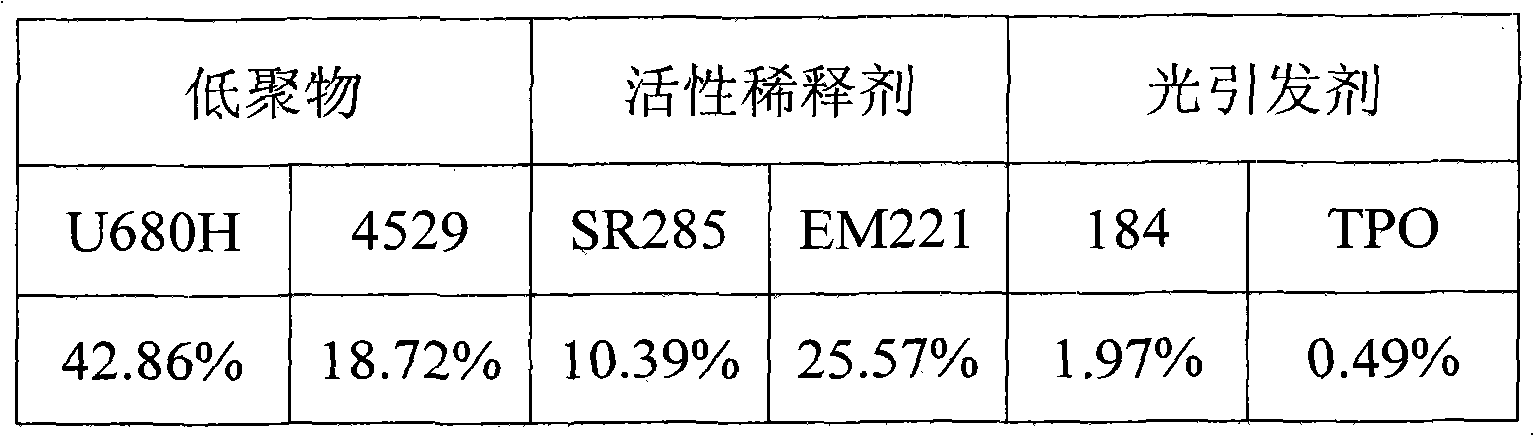

[0067] The composition of UV curing adhesive is as follows:

[0068]

[0069] Add oligomers, monofunctional reactive diluents, and multifunctional reactive diluents into the container according to the proportions in the above table, and mix with an electric stirrer for 10 minutes; then add the photoinitiator in proportion, and then stir with an electric stirrer for 10 minutes to mix; Finally, let stand for 24 hours or vacuum for 2 hours to remove air bubbles in the UV-curable adhesive.

Embodiment 2

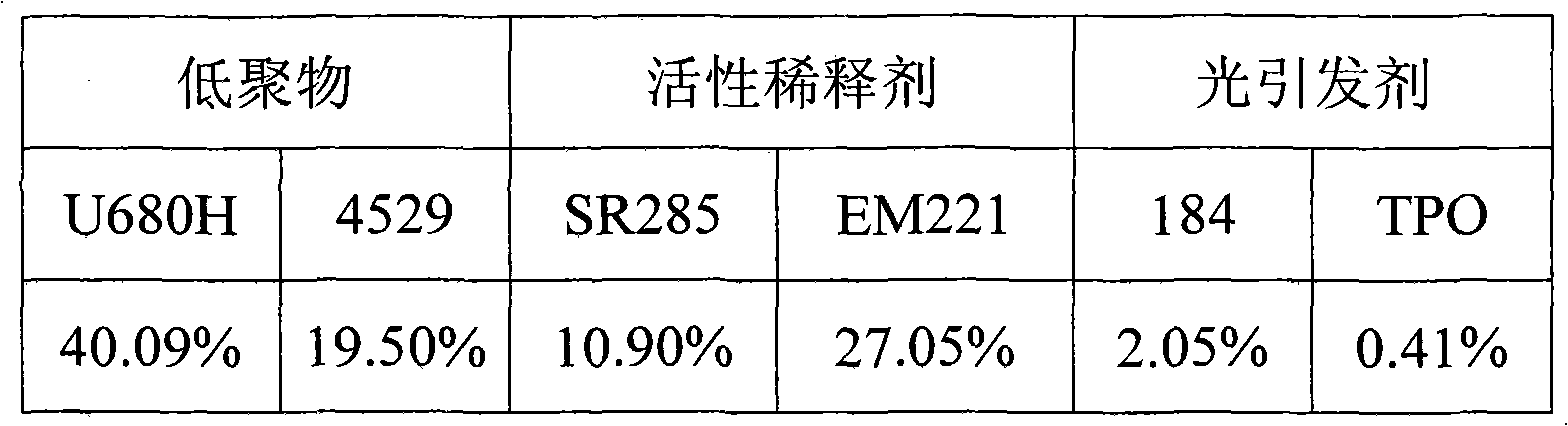

[0071] The composition of UV curing adhesive is as follows:

[0072]

[0073] Prepare according to the method of embodiment 1.

Embodiment 3

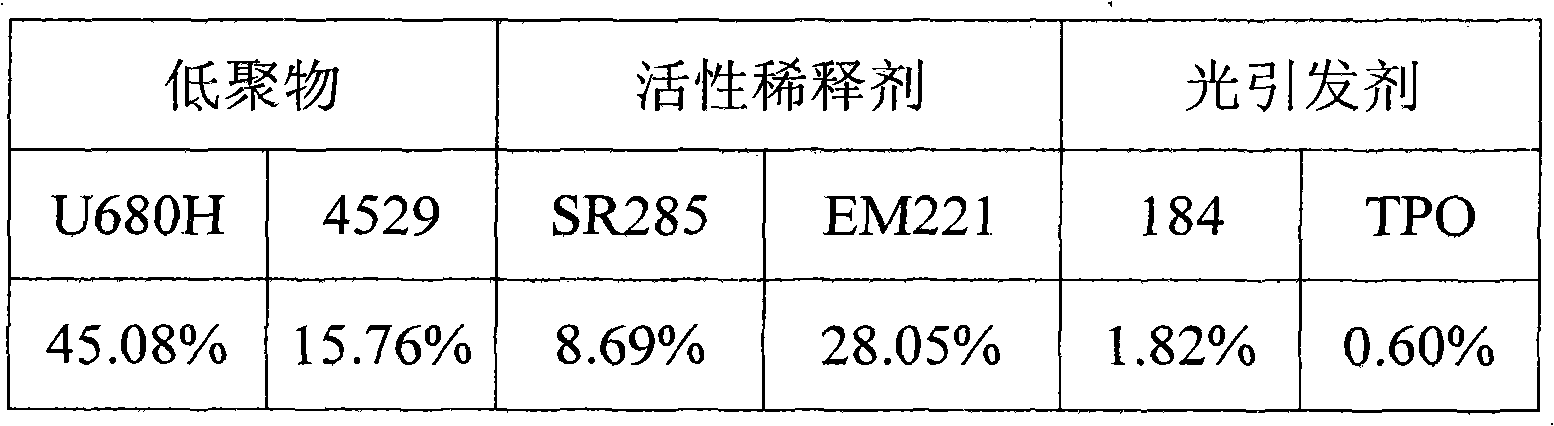

[0075] The composition of UV curing adhesive is as follows:

[0076]

[0077] Prepare according to the method of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com