Method for extracting porphyra polysaccharide and porphyra protein

A technology of laver polysaccharides and extraction methods, applied in food preparation, food science, applications, etc., can solve the problems of low extraction yield, weak competitiveness, and low added value of laver products, achieve high biological activity, increase economic value and The effect of social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

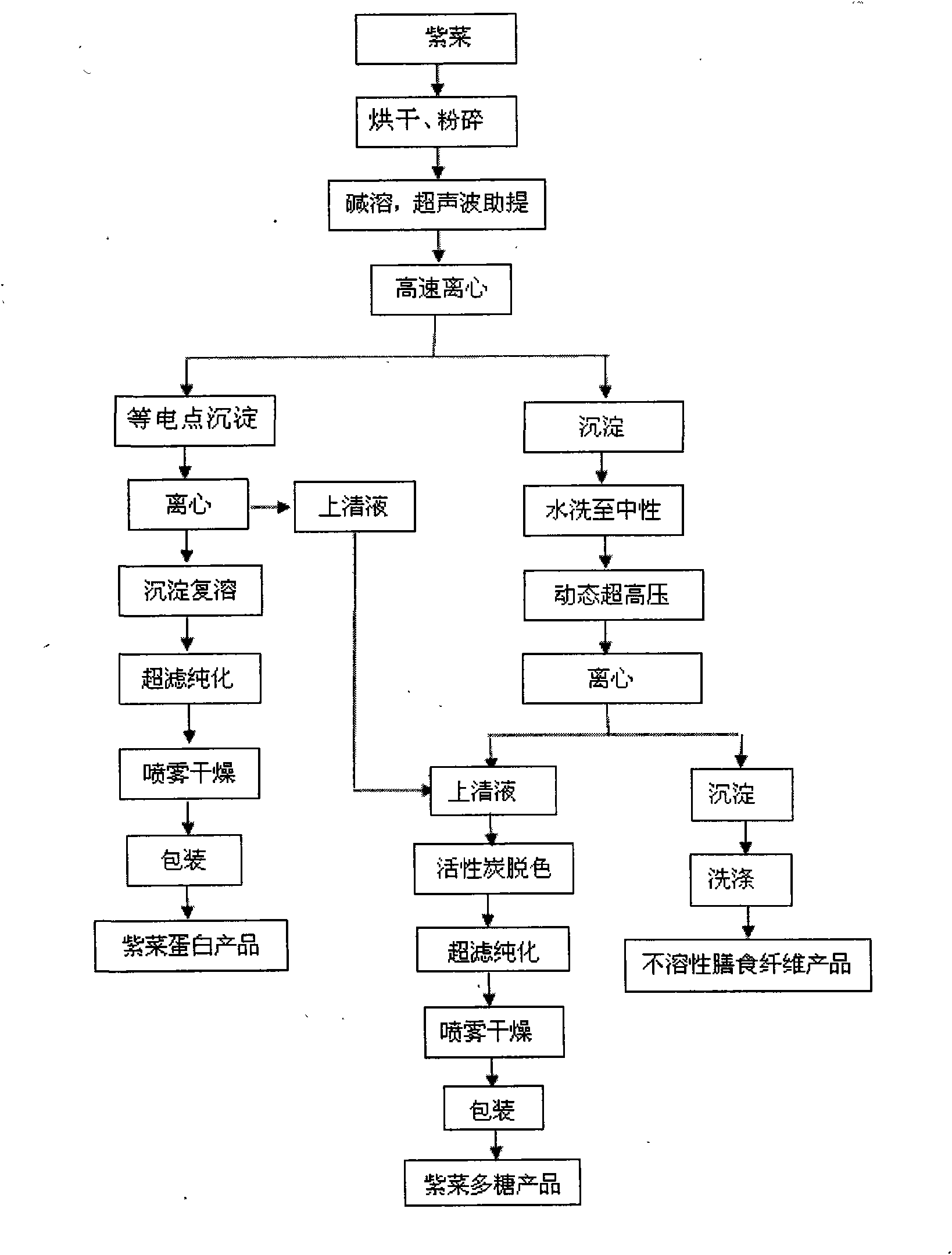

Image

Examples

Embodiment 1

[0023] (1) Drying and pulverization: Bake the seaweed at 50°C for 12 hours, and pulverize it to make seaweed dry powder.

[0024] (2) Alkali-soluble, ultrasonic technology-assisted extraction: pH is 8, the solution dosage is 40 times that of the dried seaweed powder, the ultrasonic temperature is 50°C, the time is 30min, and the power is 150W.

[0025] (3) High-speed centrifugation: the extraction liquid was centrifuged at high speed for 10 min under the condition of 4000 r / min, the supernatant was used to prepare laver protein, and the precipitation was used to extract laver polysaccharide.

[0026] (4) Isoelectric point precipitation: adjust the pH of the centrifuged supernatant to 5, and after standing for 15 minutes, centrifuge at a high speed for 10 minutes under the condition of 4000 r / min, the resulting precipitate is porphyrin, and the supernatant is a polysaccharide extract .

[0027] (5) Ultrafiltration and purification of protein: The protein obtained by isoelectri...

Embodiment 2

[0033] (1) drying, pulverizing: same as Example 1.

[0034] (2) Alkali-soluble, ultrasonic technology-assisted extraction: pH is 8.5, the solution dosage is 60 times that of the dried seaweed powder, the ultrasonic temperature is 30°C, the time is 45min, and the power is 200W.

[0035] (3) high-speed centrifugation: same as Example 1.

[0036] (4) Isoelectric point precipitation: adjust the pH of the centrifuged supernatant to 4, and after standing for 22 min, centrifuge at a high speed for 10 min under the condition of 4000 r / min, the obtained precipitate is porphyrin, and the supernatant is a polysaccharide extract .

[0037] (5) Ultrafiltration and purification of protein: The protein obtained by isoelectric precipitation was prepared into a 5% solution with purified water, and a membrane with a molecular weight cut-off of 10,000 Da was used for separation and purification. The feed pressure is 0.15MPa, the pH is 8, the temperature is 35°C, and the tangential flow rate is...

Embodiment 3

[0043] (1) drying, pulverizing: same as Example 1.

[0044] (2) Alkali-soluble, ultrasonic technology-assisted extraction: pH is 9, the solution dosage is 20 times that of the dried seaweed powder, the ultrasonic temperature is 40°C, the time is 60min, and the power is 100W.

[0045] (3) high-speed centrifugation: same as Example 1.

[0046] (4) Isoelectric point precipitation: adjust the pH of the centrifuged supernatant to 4.5, and after standing for 30 min, centrifuge at a high speed for 10 min under the condition of 4000 r / min, the resulting precipitate is porphyrin, and the supernatant is a polysaccharide extract .

[0047] (5) Ultrafiltration and purification of protein: The protein obtained by isoelectric precipitation was prepared into a 3% solution with purified water, and a membrane with a molecular weight cut-off of 20,000 Da was used for separation and purification. The feed pressure is 0.2MPa, the pH is 7, the temperature is 45°C, and the tangential flow rate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com