Method and device for dissolving gas in liquid-phase circulating hydrodesulfurization system

A liquid-phase circulating hydrogenation and desulfurization system technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as high cost, poor mixing effect, and complex system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In a 200,000-ton / year liquid-phase circulation hydrogenation unit, the oil-gas mixing process is reformed according to the present invention.

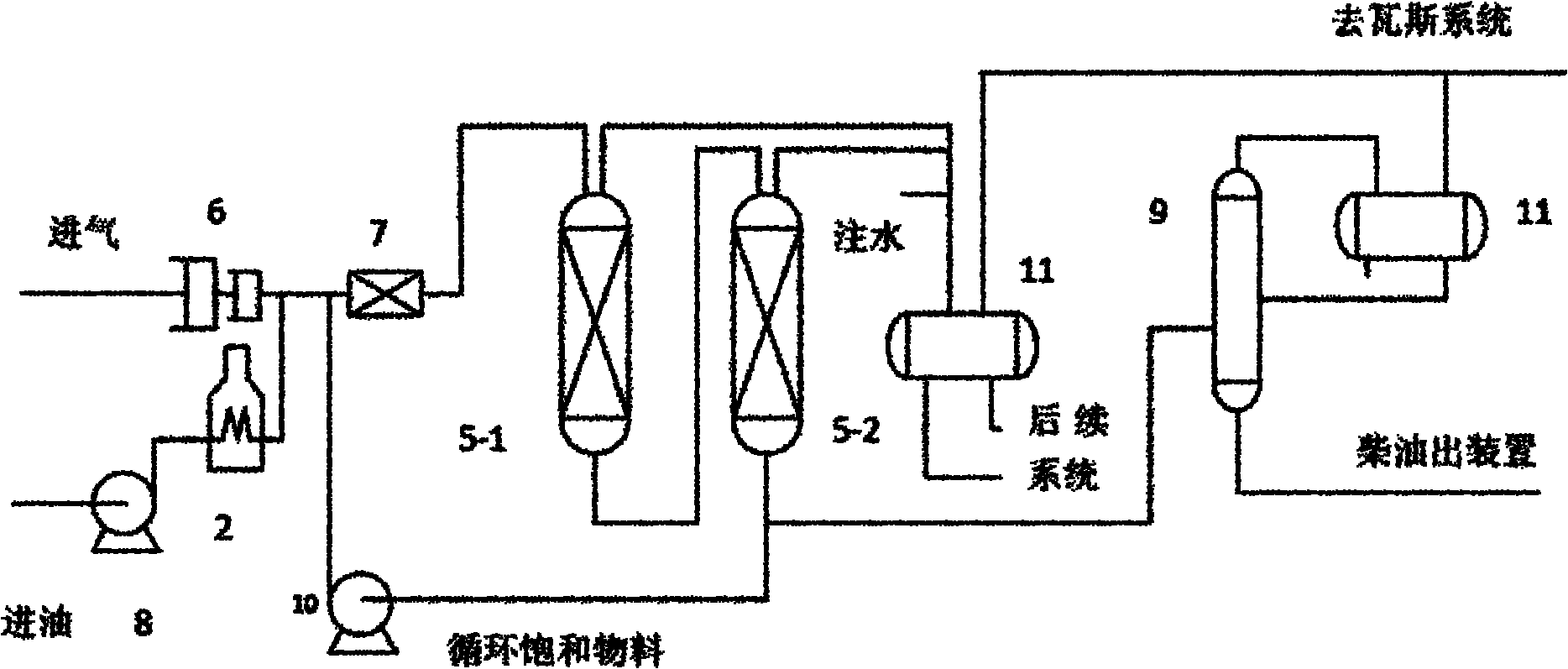

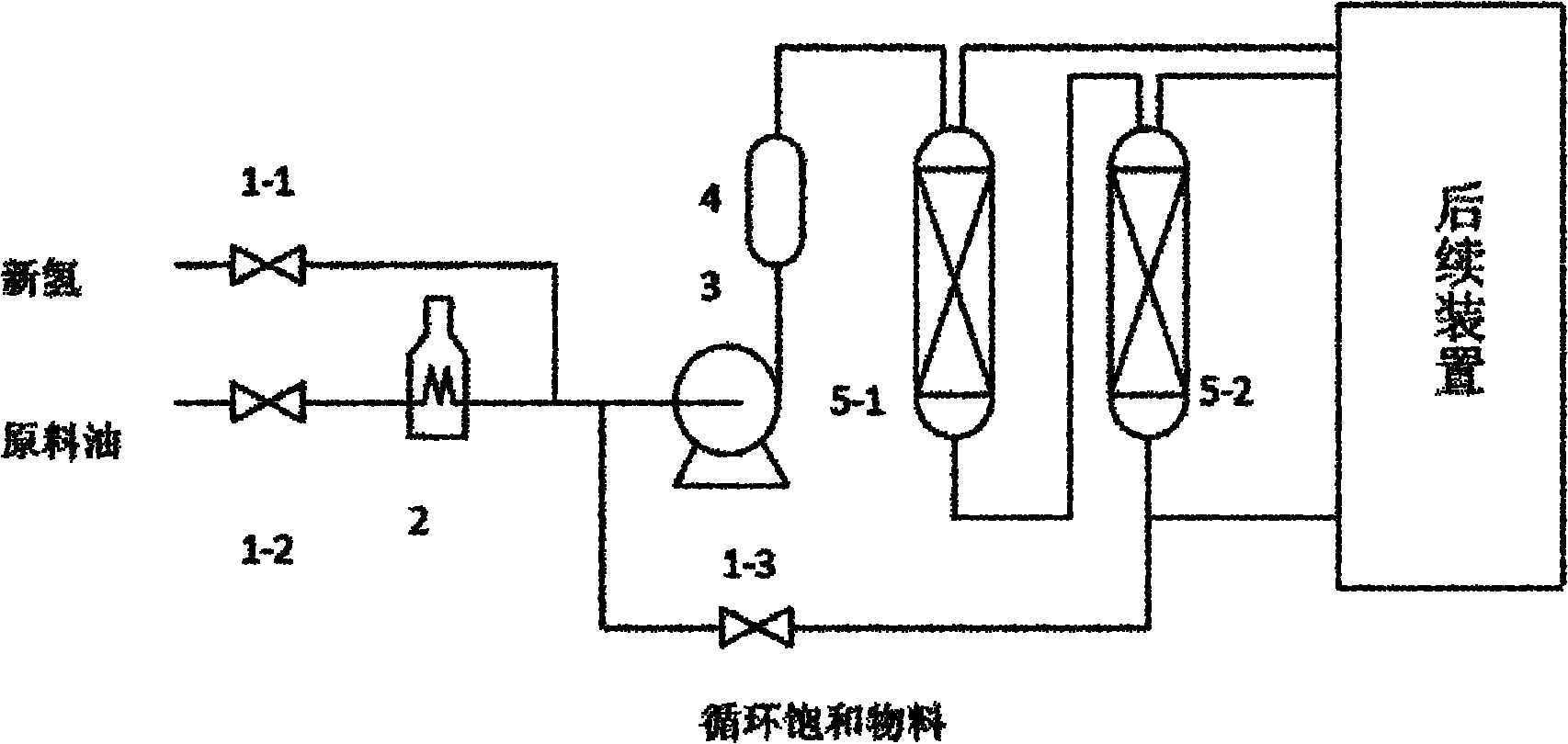

[0055] Process flow:

[0056] Specific process such as figure 2 As shown, the raw material parameters are shown in Table 1 below, and the main operating conditions are shown in Table 2 below:

[0057] Table 1

[0058]

[0059] Table 2

[0060]

[0061] Technical effect:

[0062] Because the mixing effect of the pump improves the mixing degree of oil and gas before entering the reactor, and the recirculating hydrogen mixture material retains a certain reaction heat, which can greatly improve the hydrogenation reaction efficiency. Compared with other gas-liquid mixing methods, the gas-liquid mixing pump is used as a mixing method, and can also be used as a circulation pump in the system at the same time, which simplifies the system and saves costs. The adoption of this method can produce huge economic benefits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com