Method for preparing reaction-type perfume material by using extraction residues

A residue and raw material technology, which is applied in the field of Maillard reaction to prepare tobacco flavors, can solve the problems of environmental protection, waste, and environmental pollution, and achieve the effects of environmental protection, low cost, and full aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

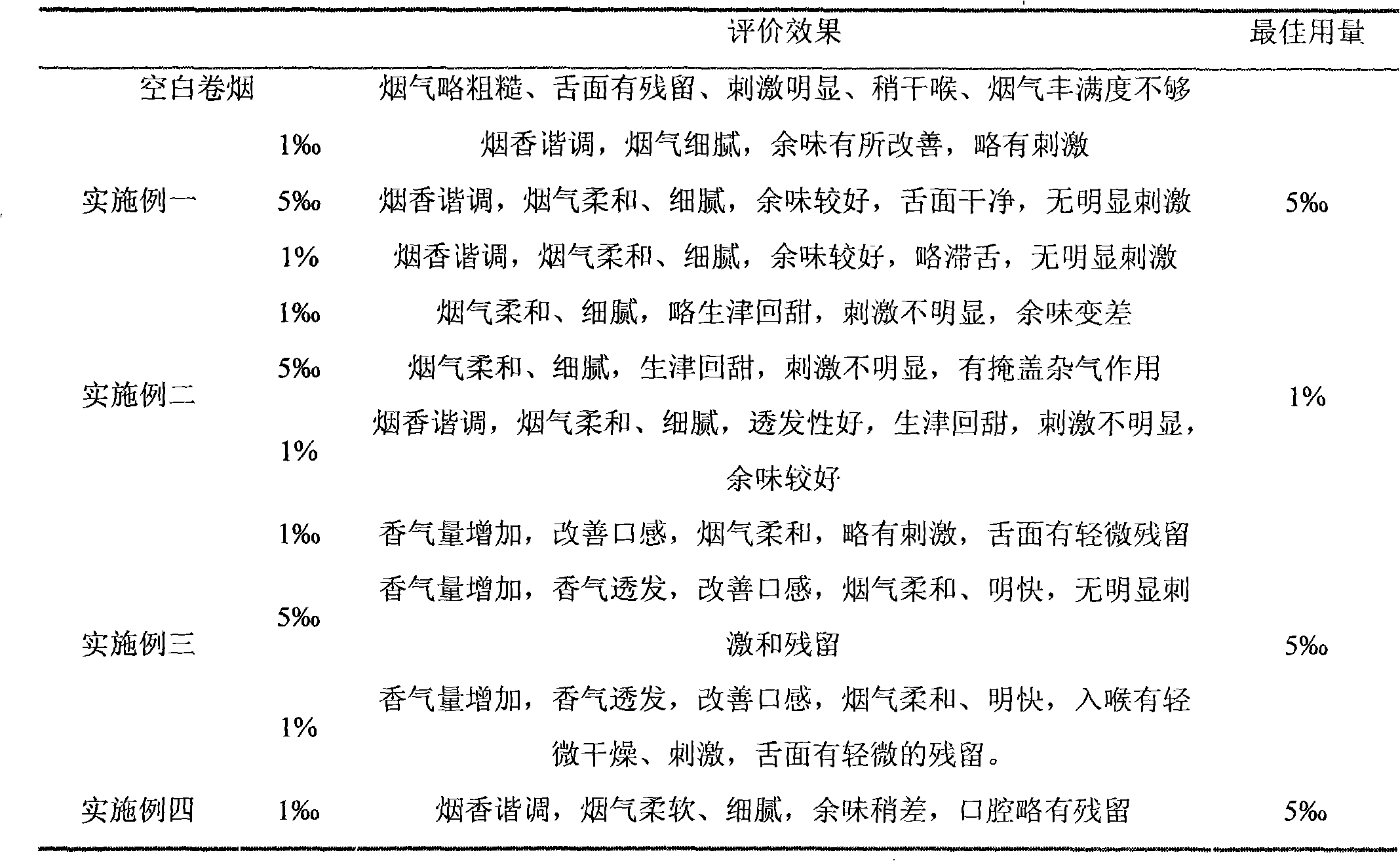

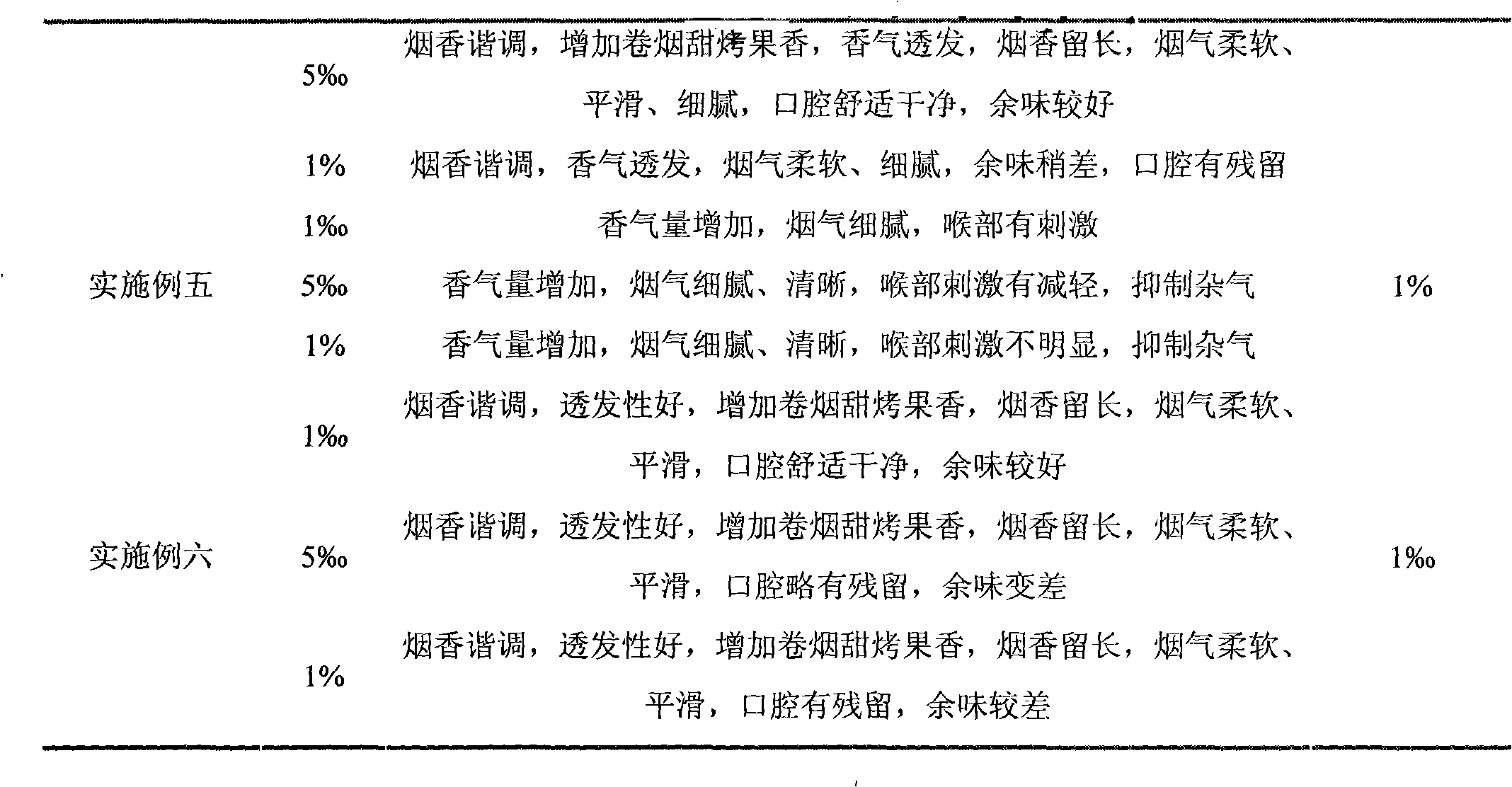

Examples

Embodiment 1

[0023] 1. Use nut shell extraction residue as raw material, add water and stir evenly, the solid content accounts for 60%, add phosphoric acid with a concentration of 60% of 25% of the total mass, stir in a water bath at 80°C for hydrolysis, and the hydrolysis time is 4 hours , and filter out a small amount of insoluble matter to obtain a cellulose hydrolyzate, which is mainly a mixture of glucose and xylose.

[0024] 2. Use soybean meal as raw material, add water and stir evenly, the solid matter accounts for 70%, add phosphoric acid with a concentration of 60% of 20% of the total mass, carry out hydrolysis under the condition of 100°C, the hydrolysis time is 4 hours, filter out a small amount of insoluble matter , to obtain a protein hydrolyzate, mainly a mixture of amino acids.

[0025] 3. Mix and stir the nut shell residue hydrolyzate and soybean meal hydrolyzate at a ratio of 1:1.2, adjust the pH value to 7.5, add 2% ascorbic acid, and heat and reflux for 4 hours under no...

Embodiment 2

[0029] 1. Take chaff residue as raw material, stir evenly after adding water, the solid matter accounts for 55%, add phosphoric acid with a concentration of 55% of 15% of the total mass, stir in a water bath at 75°C for hydrolysis, and the hydrolysis time is 6 hours. A small amount of insoluble matter is filtered to obtain a cellulose hydrolyzate, mainly reducing sugars such as glucose, xylose, and fructose.

[0030] 2. Use soybean meal as raw material, add water and stir evenly, the solid matter accounts for 70%, add phosphoric acid with a concentration of 55% of 20% of the total mass, carry out hydrolysis under the condition of 100°C, the hydrolysis time is 4 hours, filter out a small amount of insoluble matter , to obtain soybean meal protein hydrolyzate, which is mainly a mixture of amino acids.

[0031] 3. Mix and stir the chaff hydrolyzate and soybean meal protein hydrolyzate in a ratio of 1:1.2, adjust the pH value to 8, add 2% ascorbic acid, and heat and reflux for 4 h...

Embodiment 3

[0034] 1. Use red jujube extraction residue as raw material, add water and stir evenly, the solid matter accounts for 60%, add 25% of the total mass of phosphoric acid with a concentration of 65%, stir in a water bath at 80°C for hydrolysis, and the hydrolysis time is 4 hours, A small amount of insoluble matter is removed by filtration to obtain a cellulose hydrolyzate, which is mainly a mixture of glucose, xylose and fructose.

[0035] 2. Use soybean meal as raw material, add water and stir evenly, the solids account for 70%, add 20% of the total mass of phosphoric acid with a concentration of 65%, hydrolyze at 100°C, hydrolysis time is 4 hours, filter to remove a small amount of insoluble The product is obtained to obtain soybean meal protein hydrolyzate, which is mainly a mixture of amino acids.

[0036] 3. Mix and stir the jujube residue hydrolyzate and soybean meal protein hydrolyzate in a ratio of 1:1, adjust the pH value to 8, add 1% malonic acid, heat and reflux at nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com