Spiral-stirrup square steel tube concrete column and manufacturing method thereof

A technology of spiral stirrups and concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of ignoring the hoop effect of square steel pipes, unfavorable architectural effects, and difficult connection of building panels, so as to achieve the convenience of fireproof panels and restraint capacity The effect of strengthening and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

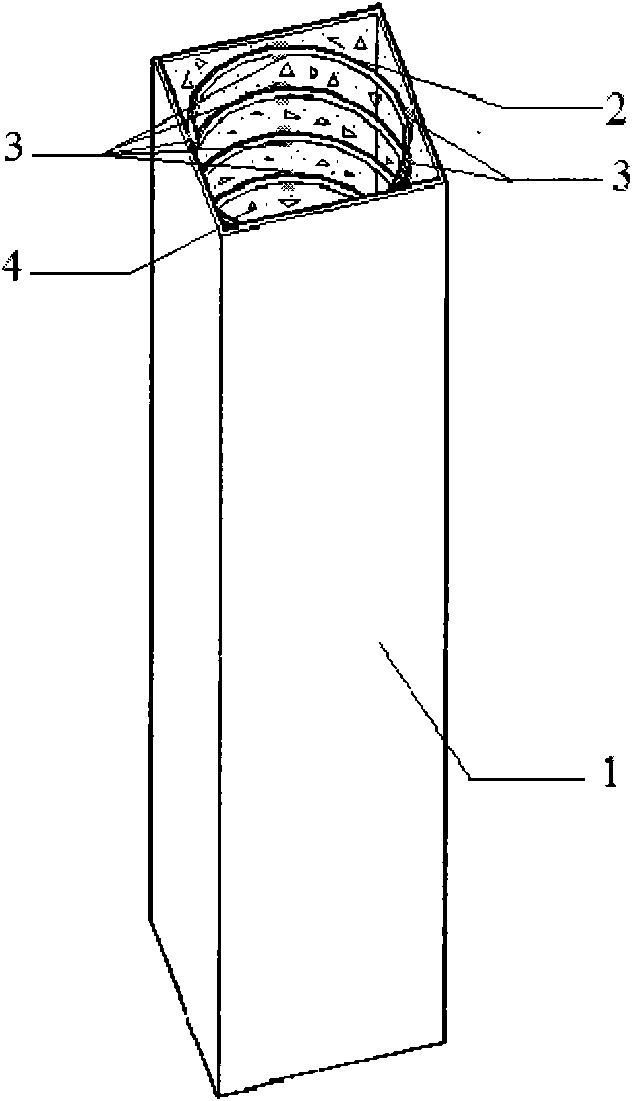

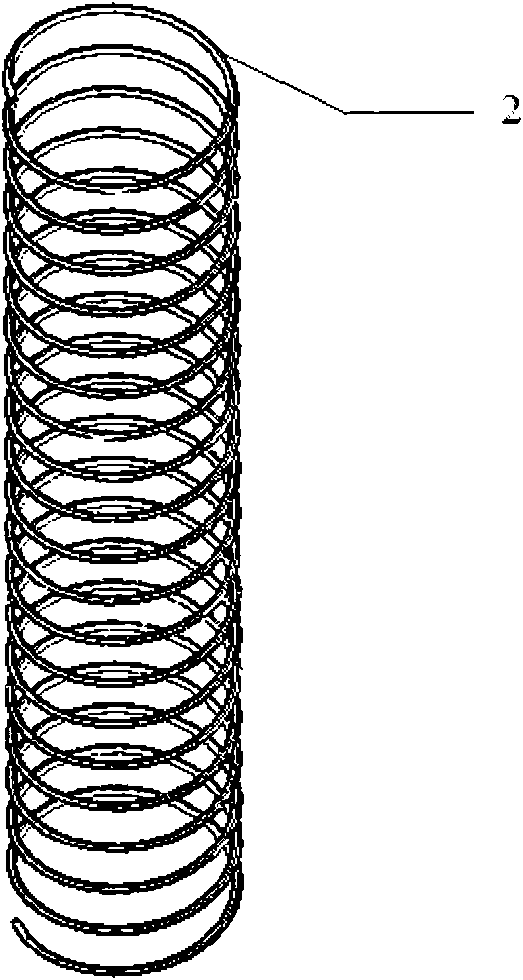

[0021] Such as figure 1 As shown: the spiral stirrup square steel pipe concrete column includes a square steel pipe 1, a spiral stirrup 2 and concrete 4 poured in the square steel pipe. Such as figure 2 Shown, is the square steel pipe that adopts in this invention. Such as image 3 A spiral stirrup is formed by looping the rebar into a helix as shown. Then put the tied spiral stirrup into the square steel pipe, and spot weld 3 at the edges of both ends (such as Figure 5 As shown), forming a square steel pipe with spiral stirrups (such as Figure 4 shown). The square steel pipe with spiral stirrups is erected, and then the concrete of the corresponding label is poured according to the design requirements, and after 28 days of curing, a square steel pipe concrete column with spiral stirrups is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com