Plate air preheater

An air preheater, plate type technology, applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of long manufacturing cycle and large welding workload, and achieve simple production and good sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

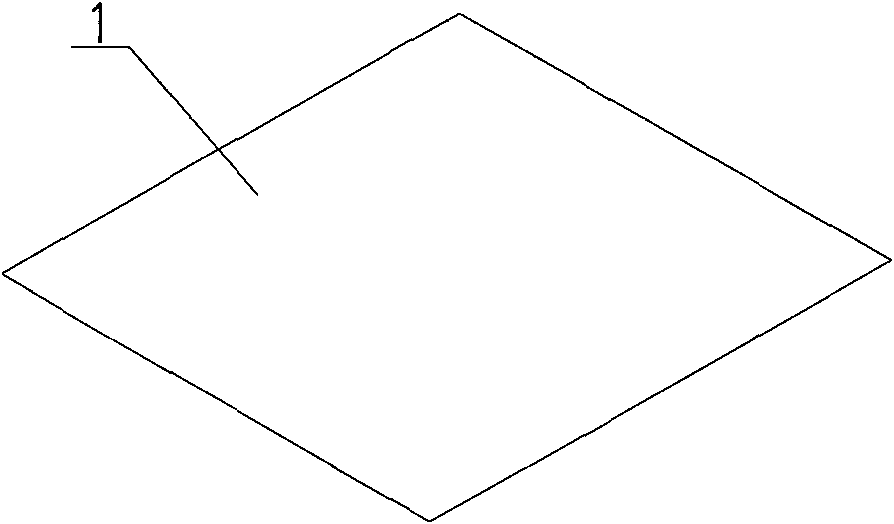

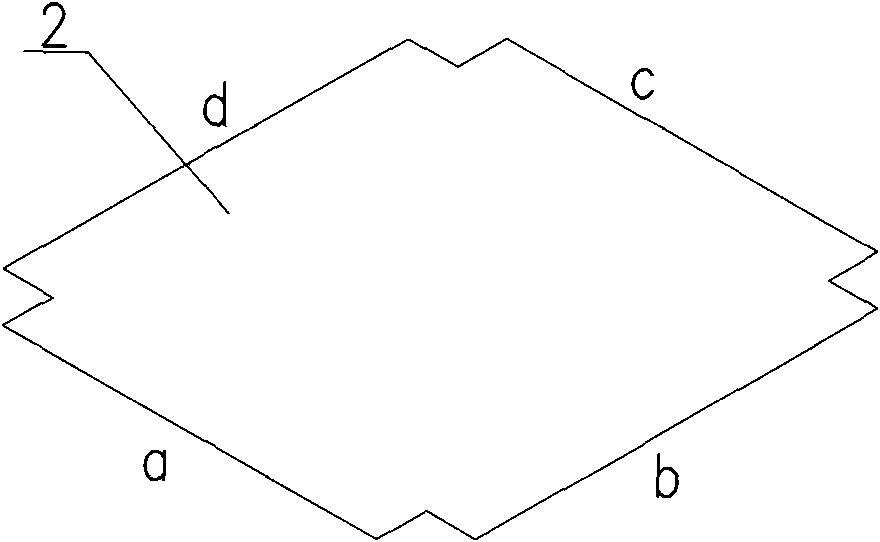

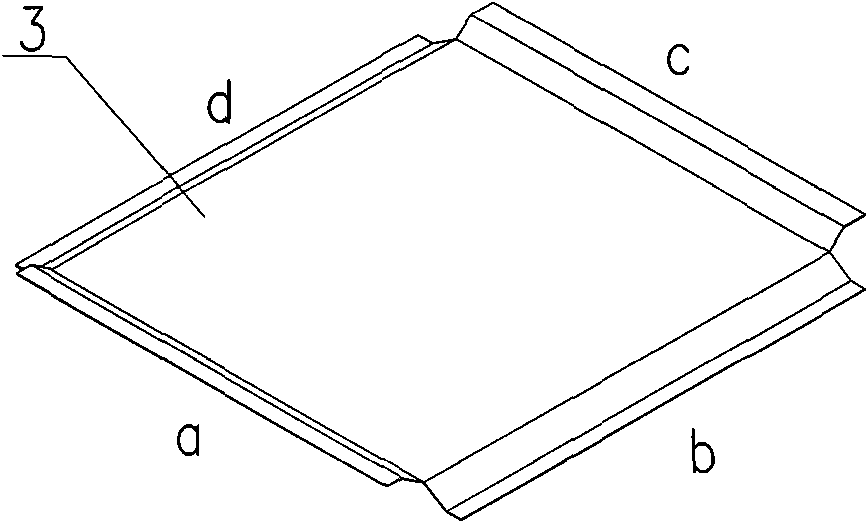

[0037] like Figure 1-Figure 18 As shown, the four corners of the heat transfer plate 1 are cut off, and after the four corners are cut off, the plate 2 is folded, wherein the sides a and c are folded upward, and the sides b and d are folded downward. The rib support 4 is turned over, and the lower surface vertical rib support 5 is welded to the lower surface of the sheet 3 after hemming, so far to form a basic plate shape.

[0038] The basic plate type is interlocked in two, and the interlocking opposite sides are aa and cc. Each side is clamped with a U-shaped trim 6. After the U-shaped trim 6 is stuck, open holes together with the U-shaped trim 6 and the two sides of aa and cc. , and riveted with rivets 7 to form a single-channel core 8 . Then weld the four-corner sealing angle steel 9 at the four corners of the single-channel core 8, so that the four corners of the single-channel core 8 are completely sealed, and then superimpose and interlock a single-channel core 8, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com