Optically isotropic liquid crystalline medium, and optical element

An optical isotropic and liquid crystal phase technology, applied in optics, liquid crystal materials, nonlinear optics, etc., can solve problems such as high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0205] The preparation of the liquid crystal composition of the present invention is generally carried out by a known method, for example, a method of dissolving essential components at a high temperature.

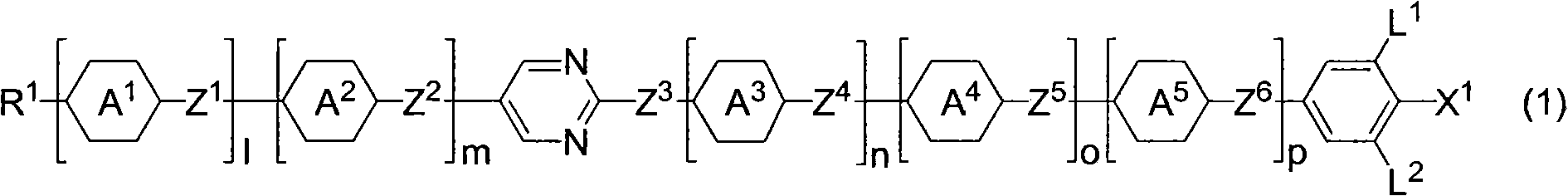

[0206] 3 Compound (15)~Compound (19)

[0207] The third aspect of the present invention is a liquid crystal composition obtained by adding to component A a component selected from components F and G shown below.

[0208] The component that can be added to component A is preferably component F containing at least one compound selected from the group consisting of the above formulas (15), (16), (17) and (18), or containing A component obtained by mixing component G of at least one compound selected from the group consisting of the above formula (19).

[0209] In addition, among the components of the liquid crystal composition used in the present invention, analogues including isotopes of the respective elements can also be used because there is no significant difference in ...

Embodiment

[0321] Since the obtained compounds were obtained by 1 Since nuclear magnetic resonance spectra obtained by H-NMR analysis, gas chromatograms obtained by gas chromatography (GC) analysis, etc. are used for identification, the analysis method will be described first.

[0322] 1 H-NMR analysis: DRX-500 (manufactured by Bruker BioSpin Co., Ltd.) was used as a measurement device. For the measurement, the samples prepared in Examples etc. were dissolved in CDCl 3etc. in a deuterated solvent that can dissolve the sample, and at room temperature at 500 MHz with 24 cumulative times. In addition, in the description of the obtained nuclear magnetic resonance spectrum, s indicates a singlet (singlet), d indicates a doublet (doublet), t indicates a triplet (triplet), q indicates a quartet (quartet), m indicates a multiplet (multiplet). In addition, tetramethylsilane (Tetramethylsilane, TMS) was used as the standard substance of the zero point of the chemical shift δ value.

[0323] G...

Synthetic example 1

[0351] Synthesis of formula (S1-10)

[0352]

[0353] The synthesis scheme is shown in the figure below.

[0354]

[0355] Synthesis of compound (S1-4)

[0356] Put 4.0g of (S1-1) and 20ml of toluene / isooctane=1 / 1 mixed solvent into the reactor, drop 1.43g of 1,3-propanedithiol (S1-2) therein , and stirred for 30 minutes. The reaction liquid was heated to 60° C., 3.99 g of trifluoromethanesulfonic acid (S1-3) was added dropwise, and stirred at 60° C. for 1 hour and then at 90° C. for 2 hours. After cooling to room temperature, the solvent was distilled off under reduced pressure, tert-butyl methyl ether was added, and the mixture was filtered. 4.30 g of compound (S1-4) were obtained by drying the obtained solid content.

[0357] Synthesis of compound (S1-6)

[0358] 1.38 g of 3,4,5-trifluorophenol (S1-5), 1.02 g of triethylamine, and 20 ml of dichloromethane were charged into a reactor under a nitrogen atmosphere, and cooled to -70°C. A mixture of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interval | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com