Online method for sterilizing and inhibiting bacteria of reverse osmosis membranes

A technology of reverse osmosis membrane and reverse osmosis, applied in chemistry and other directions, can solve the problems of low efficiency, large amount of dosing, narrow effect surface, etc., and achieve the effect of prolonging replacement frequency and reducing operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

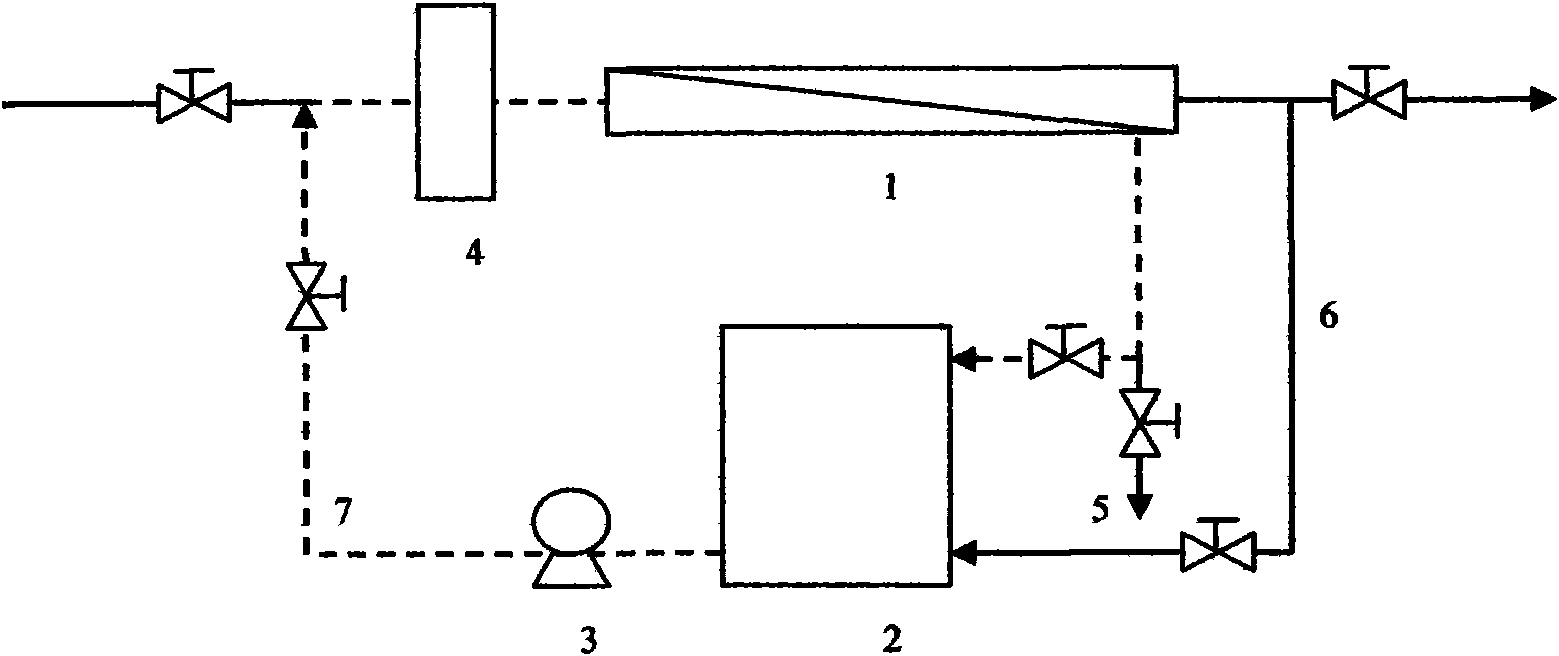

Method used

Image

Examples

Embodiment 1

[0068] The process flow of advanced treatment and reuse of oil refinery production wastewater after secondary biochemical treatment in a factory is: pretreatment-ultrafiltration-reverse osmosis, and the design influent water volume of reverse osmosis is 200m 3 / h. The reverse osmosis concentrated water quality in summer is as follows: COD is 190mg / L, TOC is 62.8mg / L, bacteria content is 1100cfu / ml, and the temperature is 40°C.

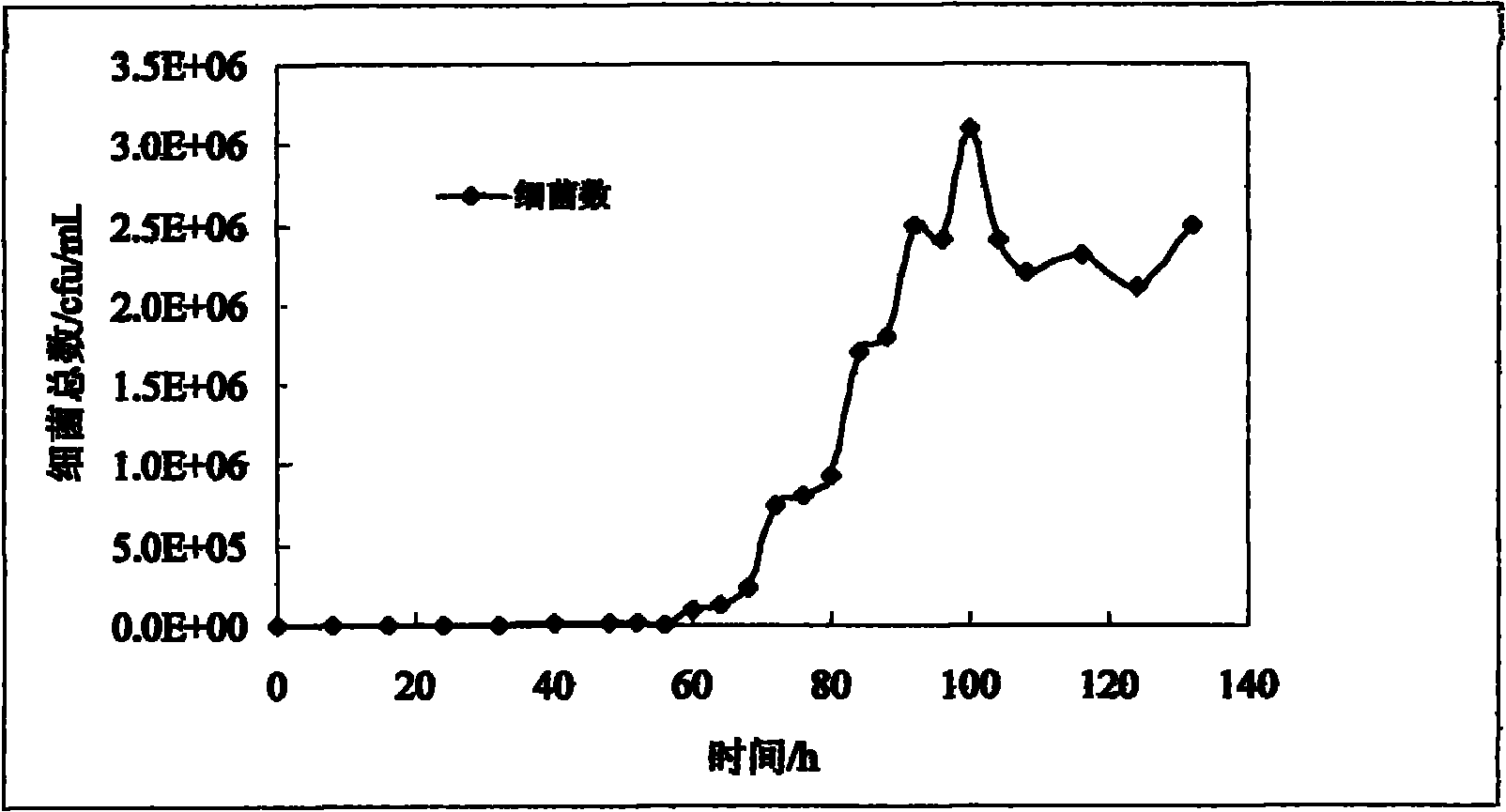

[0069] The concentrated reverse osmosis water was taken from the sampling port as the culture water source, the culture temperature was set to 40°C, the measurement frequency was once every 4-8 hours, and the culture time was set to 6 days. The bacterial growth curve at 40°C was obtained as image 3 shown.

[0070] From image 3 It can be determined that the logarithmic growth period of bacteria is 72-100h, which is about 3-4 days. It is determined that the impact sterilization cycle in summer is 3 days. The alternate cycle of two rounds of cleani...

Embodiment 2

[0077] For the wastewater reuse system in Example 1, the quality of reverse osmosis concentrated water in winter is: COD is 210mg / L, TOC is 70mg / L, bacteria content is 150cfu / m3, and the temperature is 25°C.

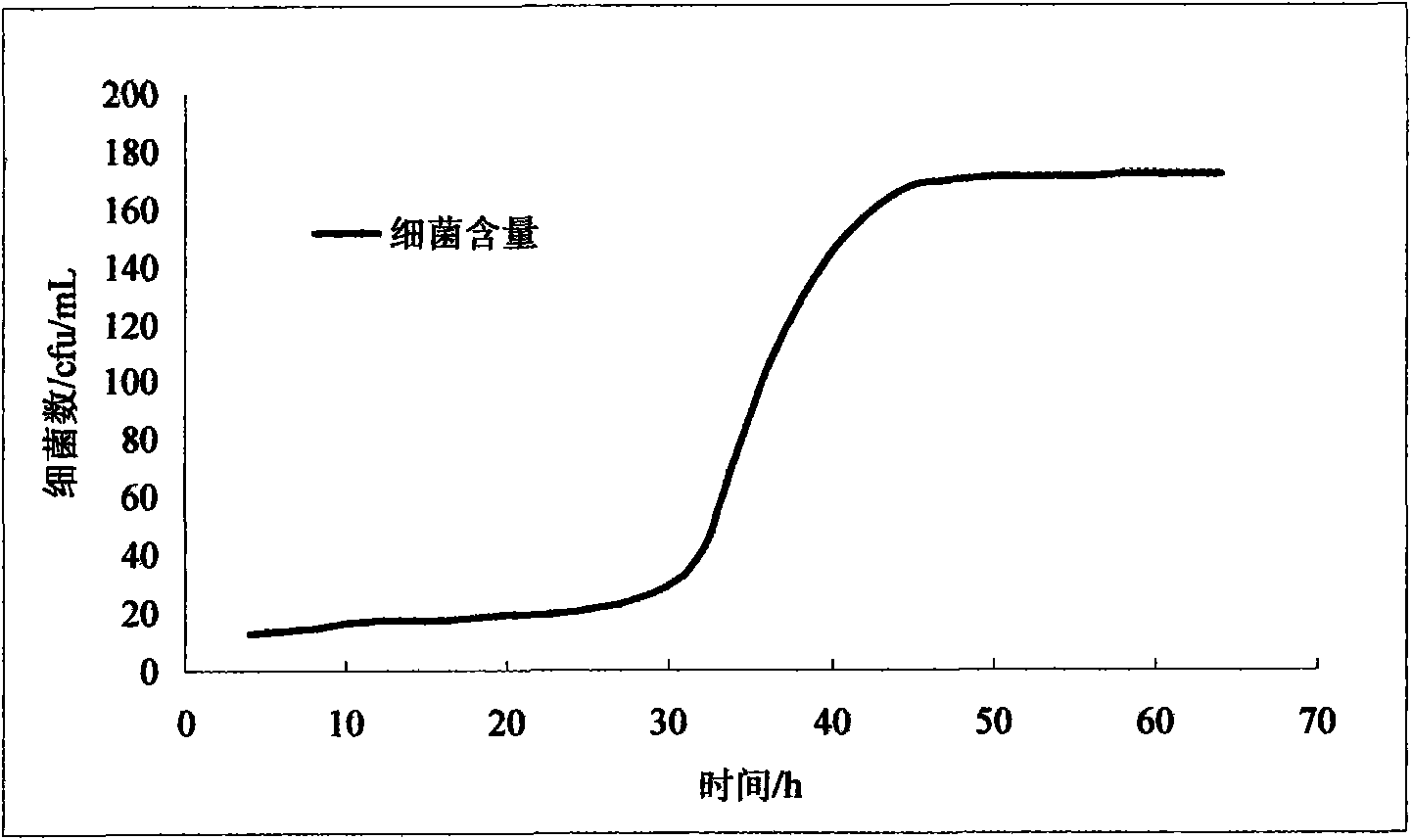

[0078] Take the concentrated reverse osmosis water from the sampling port as the culture water source, set the culture temperature as 25°C, measure the frequency as 1 time / 4-12h, and set the culture time as 12 days. The bacterial growth curve at 25°C is as follows Figure 4 shown.

[0079] From Figure 4 It can be determined that the logarithmic growth period of bacteria is 170-210h, which is about 7-9 days. It is determined that the impact sterilization cycle in winter is 7 days.

[0080] Isothiazolinone (1.5%) was selected as the fungicide for the first round of cleaning, the concentration of the prepared cleaning solution was 150 mg / L, and the alternate cycle was 2 times a cycle. The flux is 9L / m 2 h, that is, the flow rate is 100m 3 / h Inject the cleaning solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com