Method for preparing monodisperse polymer microsphere by irradiation polymerization of ultraviolet light

A polymer microsphere, monodisperse technology, applied in the field of preparation of functional polymer microspheres, can solve the problems of unfavorable energy saving, long reaction time, high temperature conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

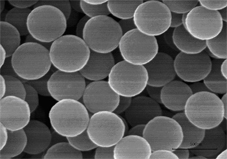

[0019] Dissolve 0.3 g of initiator 2,2-dimethoxy-2-phenylacetophenone in 70 mL of ethanol, and dissolve 0.7 g of styrene single-terminated polyisopropylacrylamide in 30 mL of water. Mix together 10g of solid styrene, place in a glass reactor, and seal it with nitrogen gas for 15 minutes while stirring; -2 mw / cm 2 Under the irradiation reaction for 24 hours; the obtained product was centrifuged and dried to obtain monodisperse polystyrene microspheres with a particle size of 320 nm and a yield of 90%. The particle size and morphology are shown in figure 1 SEM photographs.

Embodiment 2

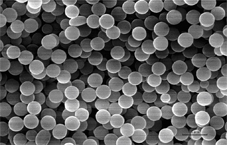

[0021] Dissolve 0.6g of 2,2-dimethoxy-2-phenylacetophenone in 70mL of ethanol, 2.0g of styrene single-terminated polyisopropylacrylamide in 30mL of water, and the two are mixed with monomer styrene 10g were mixed together, placed in a glass reactor, and sealed with nitrogen gas for 15 minutes while stirring; under the ultraviolet radiation intensity of 3.4 mw / cm 2 Under the irradiation reaction for 30 minutes; the obtained product was centrifuged and dried to obtain monodisperse polystyrene microspheres with a particle size of 428 nm and a yield of 85%. The particle size and morphology are shown in figure 2 SEM photographs.

Embodiment 3

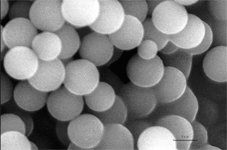

[0023] Dissolve 0.5g of 2,2-dimethoxy-2phenylacetophenone in 70mL of ethanol, and dissolve 3.0g of methacrylic acid single-capped polyethylene glycol in 30mL of water. Mix 10 g of esters together, put them into a glass reactor, and pass nitrogen gas for 15 minutes while stirring; 2 Under irradiation for 30 minutes; the resulting product was centrifuged and dried to obtain polymethyl methacrylate microspheres with a yield of 90%, and its particle size and shape were as follows: image 3 SEM photographs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com