Viscoelastic surfactant cleaning fracturing fluid gel breaker and field construction method

A surfactant and clean fracturing fluid technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of high concentration, gel breaking of clean fracturing fluid, and unsatisfactory fracturing construction, etc. Achieve the effect of clear solution, good temperature resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

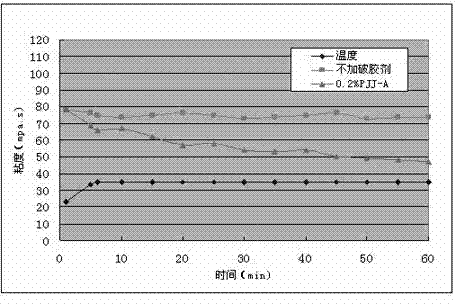

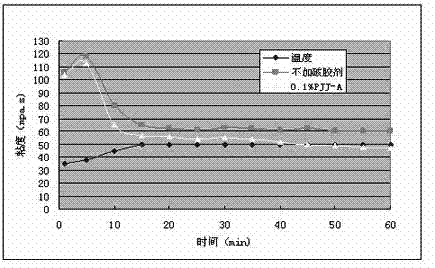

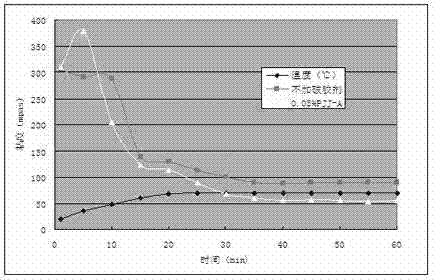

Image

Examples

Embodiment 1

[0023] Take 15g of n-hexane, chemical formula: C 6 h 14 , 10g of dodecanoic acid, chemical formula: C 12 h 24 o 2 , 30 g of petroleum ether was mixed and compounded to obtain the gel breaker of the present invention.

Embodiment 2

[0025] Take 10g of n-undecane, chemical formula: C 11 h 24 , and n-decanoic acid 10g, chemical formula: C 10 h 20 o 2 , 30 g of petroleum ether was mixed and compounded to obtain the gel breaker of the present invention.

Embodiment 3

[0027] Get n-decane 17g, chemical formula: C 10 h 22 , octadecanoic acid 10g, chemical formula: C 18 h 36 o 2 , 30 g of petroleum ether was mixed and compounded to obtain the gel breaker of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com