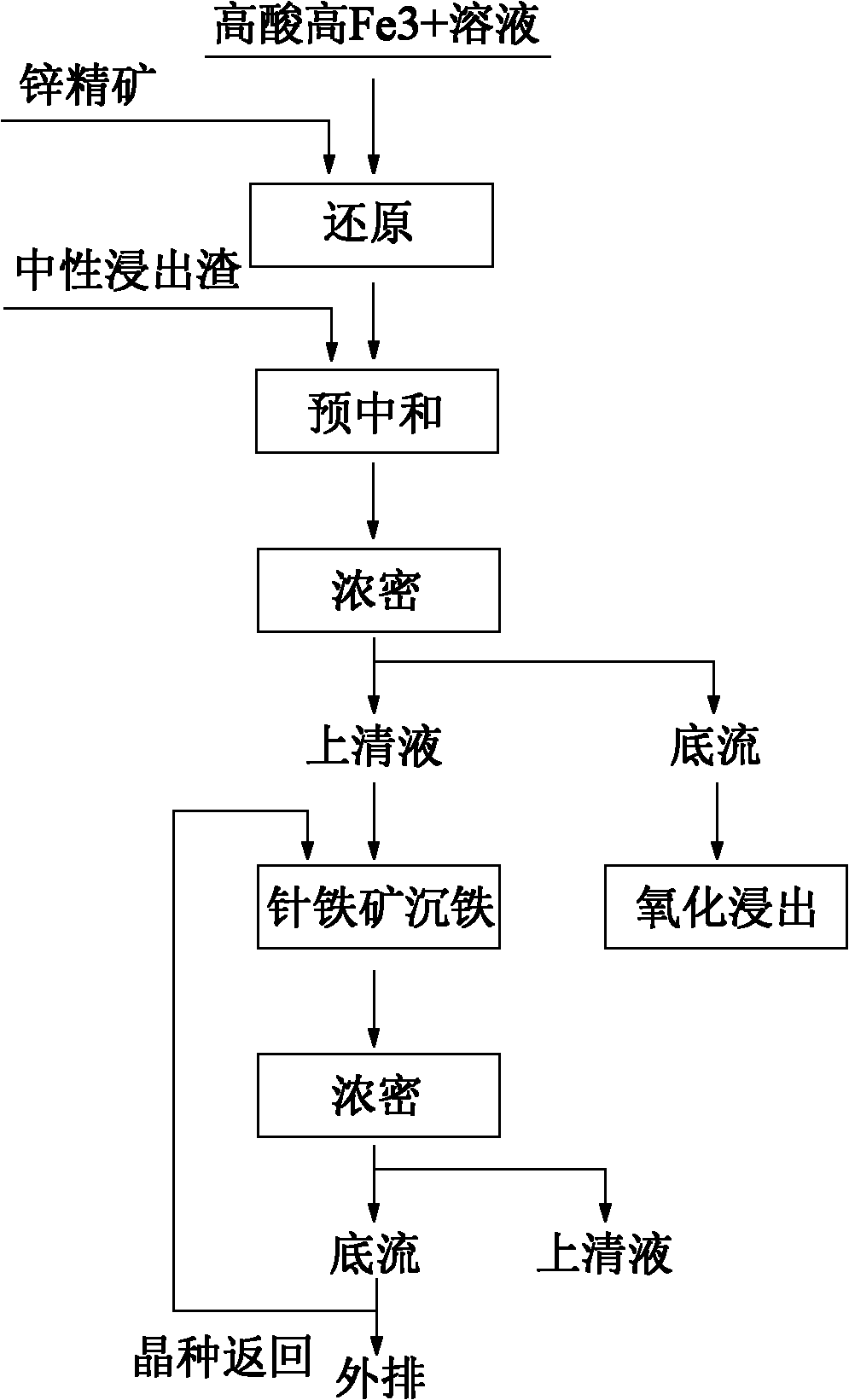

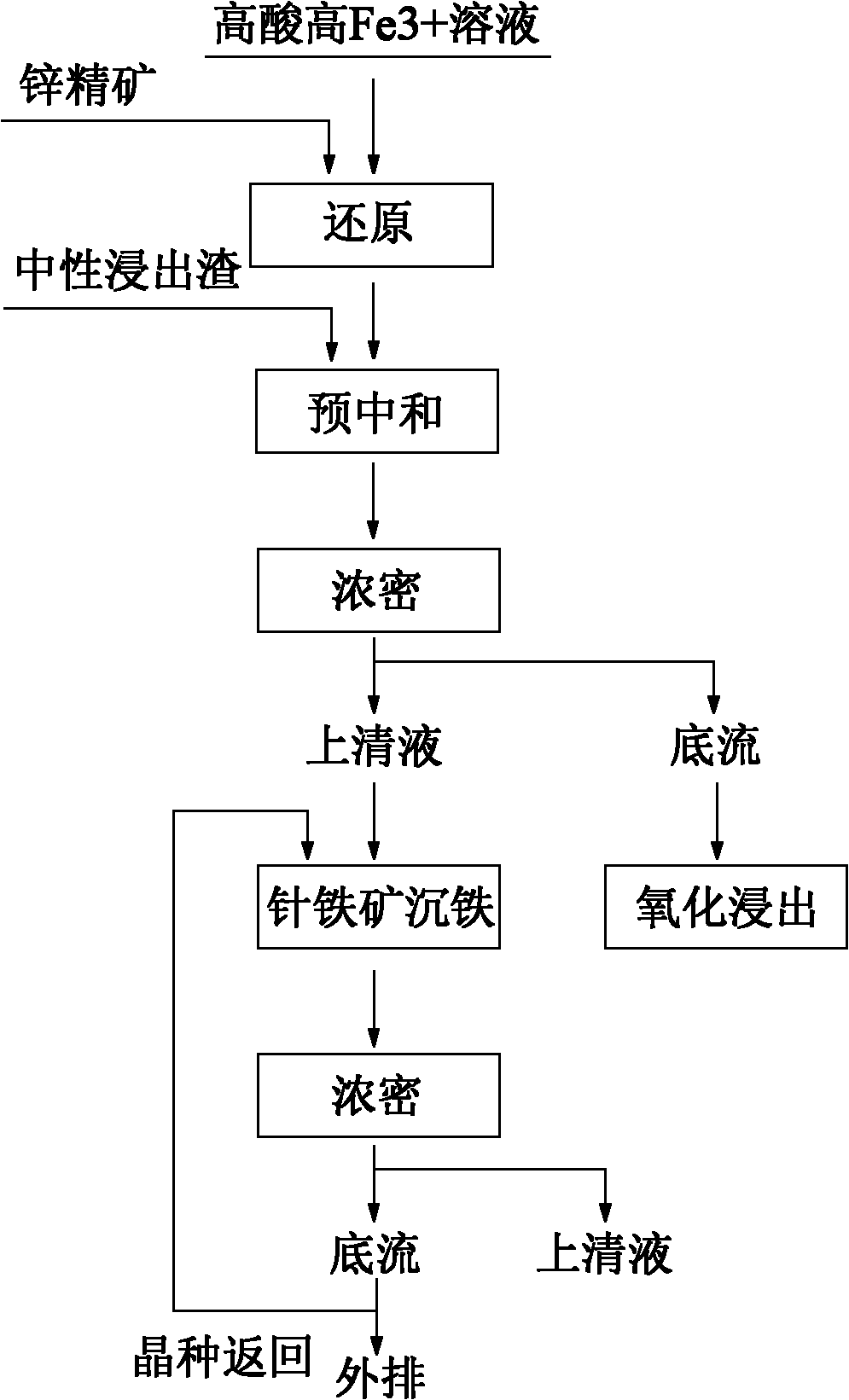

Iron depositing method of high acid and high iron solution goethite during zinc hydrometallurgy

A technology for hydrometallurgy of zinc and goethite, applied in the direction of improvement of process efficiency, etc., can solve the problems of high zinc content, impact on iron resource utilization, low iron grade, etc., and achieve improved leaching rate, simple operation, and high iron slag grade high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]a) Use zinc concentrate to treat high-acid and high-Fe 3+ The leaching solution is restored.

[0041] High Acid High Fe 3+ The chemical composition of the leachate is: Zn 2+ 138g / L, H 2 SO 4 22g / L, Cu 2+ 1.1g / L, Fe 3+ 10g / L, Fe 2+ 6g / L.

[0042] The weight percentage content of the zinc concentrate adopted is: Zn41%, S32%, Fe8%.

[0043] During reduction, the temperature is 80°C and the time is 4h.

[0044] The chemical composition of the solution after the reduction obtained is: Zn 2+ 145g / L, H 2 SO 4 22g / L, Cu 2+ 1.1g / L, Fe 3+ 0.7g / L, Fe 2+ 14.7g / L.

[0045] b) pre-neutralizing the leaching solution to a pH value of 1.5-2.5.

[0046] The neutral leaching slag produced by conventional zinc hydrometallurgy is added to pre-neutralize the leaching solution. The pre-neutralization time is 3 hours and the temperature is 80°C.

[0047] The weight percentage content of the neutral leaching slag is: Zn24%, Fe20%, Cu0.7%, S7%.

[0048] The chemical composition ...

Embodiment 2

[0055] a) Use zinc concentrate to treat high-acid and high-Fe 3+ The leaching solution is restored.

[0056] High Acid High Fe 3+ The chemical composition of the leachate is: Zn 2+ 132g / L, H 2 SO 4 25g / L, Cu 2+ 1.3g / L, Fe 3+ 13g / L, Fe 2+ 3g / L.

[0057] The weight percentage content of the zinc concentrate adopted is: Zn41%, S32%, Fe8%.

[0058] During reduction, the temperature is 100°C and the time is 3h.

[0059] The chemical composition of the solution after the reduction obtained is: Zn 2+ 138g / L, H 2 SO 4 25g / L, Cu 2+ 1.3g / L, Fe 3+ 0.9g / L, Fe 2+ 14.3g / L.

[0060] b) pre-neutralizing the leaching solution to a pH value of 1.5-2.5.

[0061] The neutral leaching slag produced by conventional zinc hydrometallurgy is added to pre-neutralize the leaching solution. The pre-neutralization time is 3 hours and the temperature is 70°C.

[0062] The weight percentage content of the neutral leaching slag is: Zn22%, Fe20%, Cu1.3%, S6.7%.

[0063] The chemical composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com