Electrolyte membrane, electrochemistry device and solid oxide fuel cell

An electrolyte diaphragm and solid oxide technology, applied in the field of electrochemistry, can solve the problems that the electrolyte diaphragm can only meet the strength requirements, and the electrolyte diaphragm cannot take into account the strength and electrical properties, and achieves the effect of meeting the strength requirements and the electrical properties requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

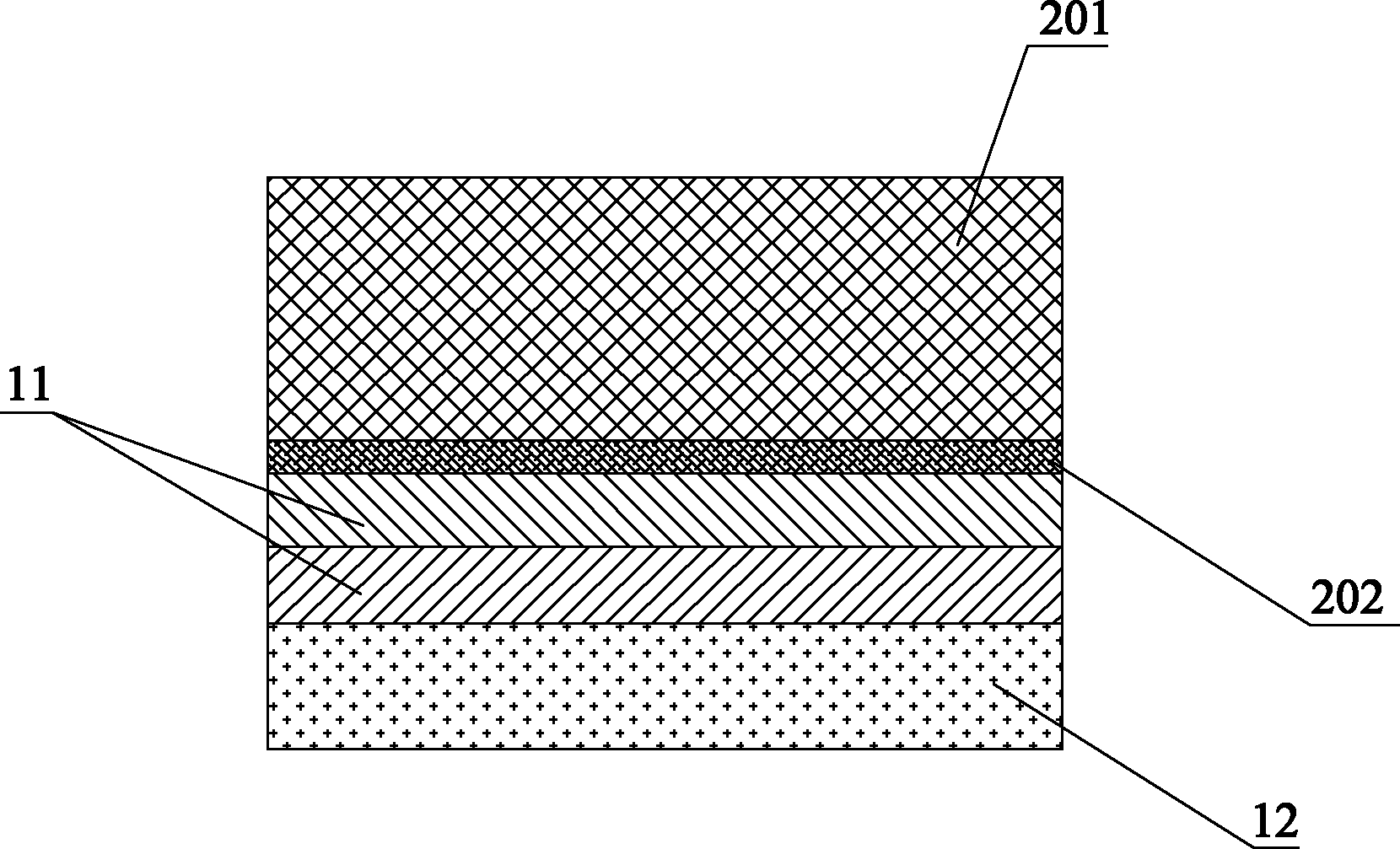

[0034] The present invention also provides the preparation method of the electrolyte diaphragm, comprising: laminating the strength-enhanced electrolyte diaphragm layer strip and the high ion conductivity electrolyte diaphragm layer strip according to a preset method and thickness, and the preset method can be alternating Laminating together, after laminating the strength-enhanced electrolyte diaphragm layer strip and the high ion conduction electrolyte diaphragm layer strip, pre-pressing is performed to obtain a pre-pressed part. The present invention does not specifically limit the pressure when applying the preload, but it is preferably 5 MPa to 20 MPa, more preferably 8 MPa to 15 MPa.

[0035] According to the present invention, the prepress can be put into a vacuum bag for vacuum treatment to remove the residual gas in the prepress, and then the preform after vacuum treatment can be press-molded to obtain a molded piece, which is preferably placed The compression molding ...

Embodiment 1

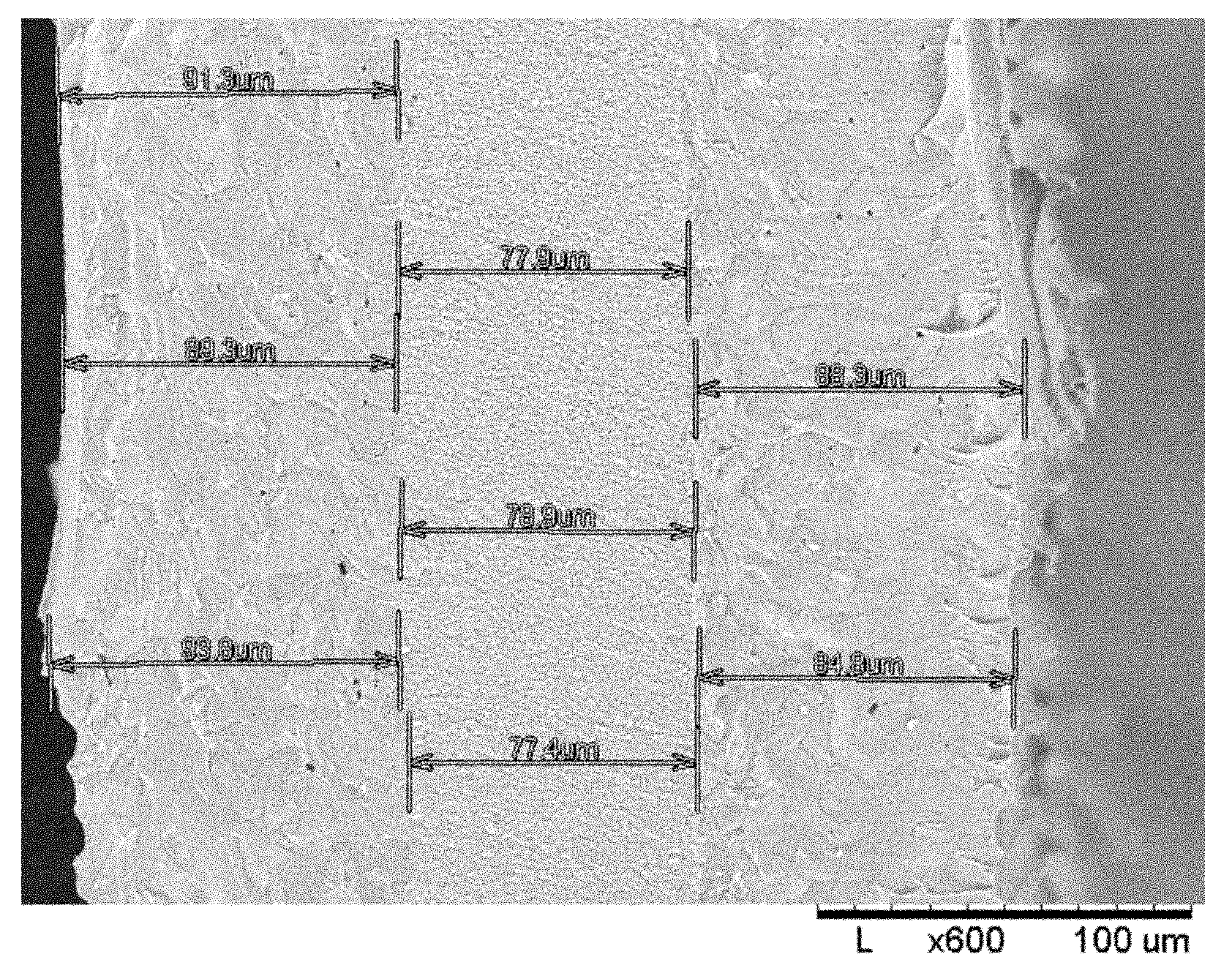

[0049] A film containing 10mol% Sc with a thickness of about 50 μm was prepared by casting method 2 o 3 and 1mol% CeO 2 ZrO 2 Strip material (hereinafter referred to as 10Sc1CeSZ); the tape-casting method is used to prepare a strip containing 3mol% Y with a thickness of about 50 μm 2 o 3 ZrO 2 Strip (hereinafter referred to as 3YSZ).

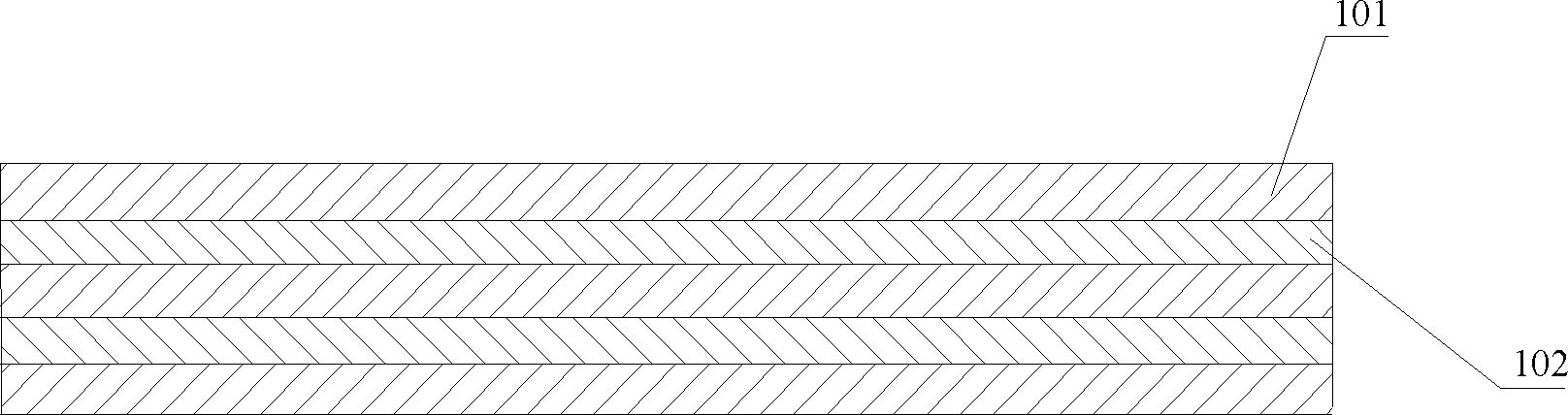

[0050] Such as figure 1 As shown, three 10Sc1CeSZ strips 101 and two 3YSZ strips 102 are alternately stacked together, and a pressure of 8 MP is applied for pre-pressing to obtain a pre-press; put the pre-press into a vacuum bag to evacuate, Then, isostatic pressing under a pressure of 50 MPa to obtain a molded part; the molded part was sintered in an air atmosphere at 1450° C. for 4 hours to obtain an electrolyte membrane with a thickness of about 210 μm.

[0051] The bending strength of the electrolyte membrane measured at room temperature is 478MPa, and the conductivity of the electrolyte membrane measured at 800°C is 0.061S / cm.

Embodiment 2

[0053] A film containing 10mol% Sc with a thickness of about 40 μm was prepared by casting method 2 o 3 and 1mol% CeO 2 ZrO 2 Strip material (hereinafter referred to as 10Sc1CeSZ); adopt tape casting method to prepare about 20 μm thickness containing 5mol% Y 2 o 3 ZrO 2 Strip (hereinafter referred to as 5YSZ).

[0054] Take five 10Sc1CeSZ strips and four 5YSZ strips and stack them together alternately, apply a pressure of 15MP for pre-press molding to obtain a pre-press; put the pre-press into a vacuum bag to vacuum, and then press the pressure of 150MPa The molding is obtained by isostatic pressing; the molding is sintered in an air atmosphere at 1450° C. for 5 hours to obtain an electrolyte membrane with a thickness of about 240 μm.

[0055] The bending strength of the electrolyte membrane measured at room temperature is 456MPa, and the conductivity of the electrolyte membrane measured at 800°C is 0.069S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com