Treatment fluid with oxidizer breaker system and method

A technology for processing fluids and breakers, applied in the directions of chemical instruments and methods, drilling compositions, etc., and can solve problems such as delay in breaking gel, less expected break width, and complex breaker system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Tests were performed using sodium bromate as the destroyer and sodium bisulfite as its activator. A 3-hour oil bath test at 175°F (79.4°C) showed that in the absence of activator, 0.06wt% sodium bromate did not destroy the fluid at this temperature, whereas 0.012wt% and 0.024wt% % additional sodium bisulfite in the fluid sample completely degrades the fluid.

Embodiment 2

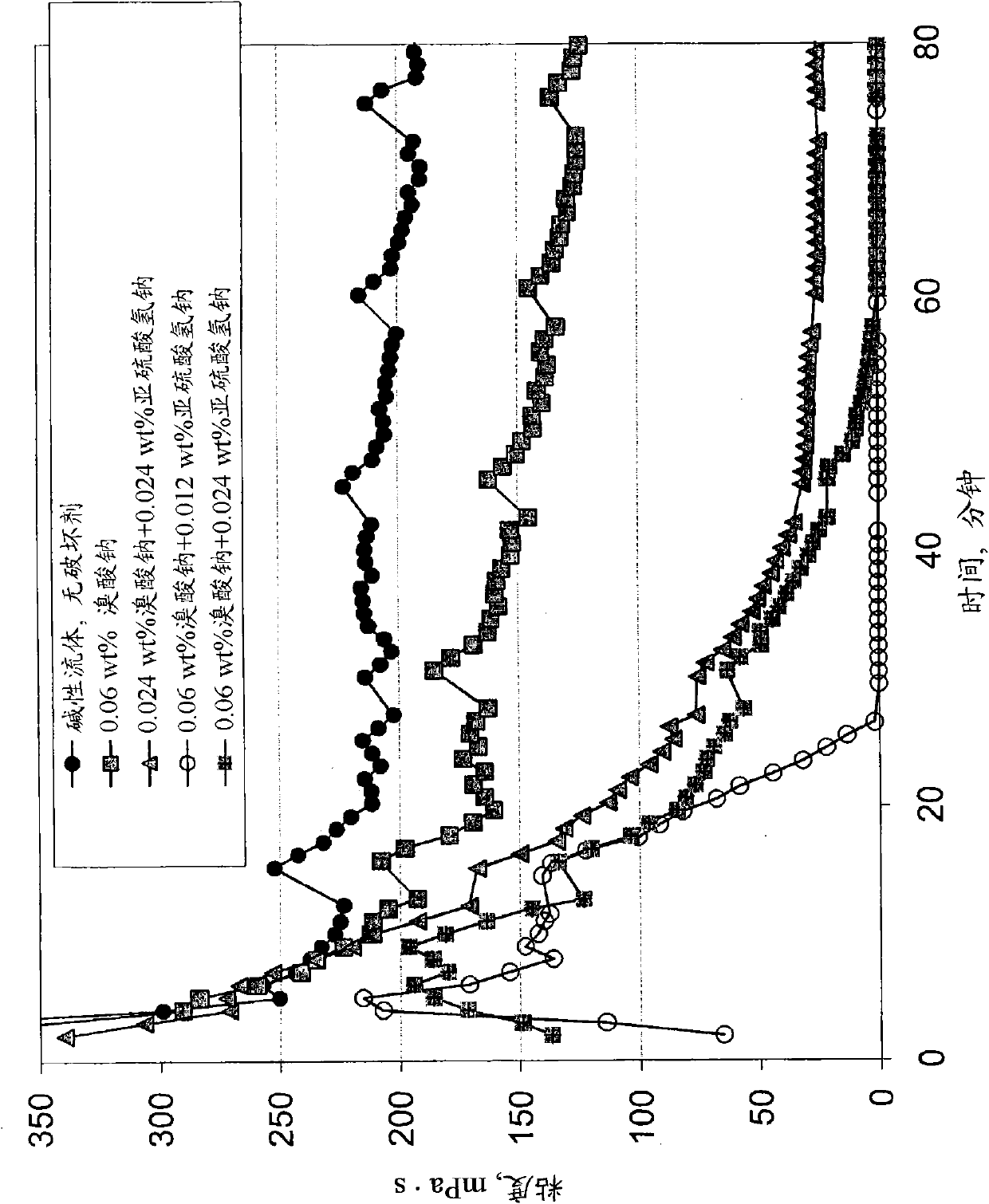

[0067] Such as figure 1 Shown in , as a comparison, cross-linked guacamole was used without breaker, with 0.06% sodium bromate breaker without any activator, and with combinations of both breaker and sodium bisulfite at different concentrations and ratios. Er gum solution for rheological studies. from figure 1 As can be seen in , sodium bromate itself cannot oxidize the fluid. Bromate / bisulfite systems are capable of oxidizing fluids at 175°F (79.4°C) and reducing viscosity.

Embodiment 3

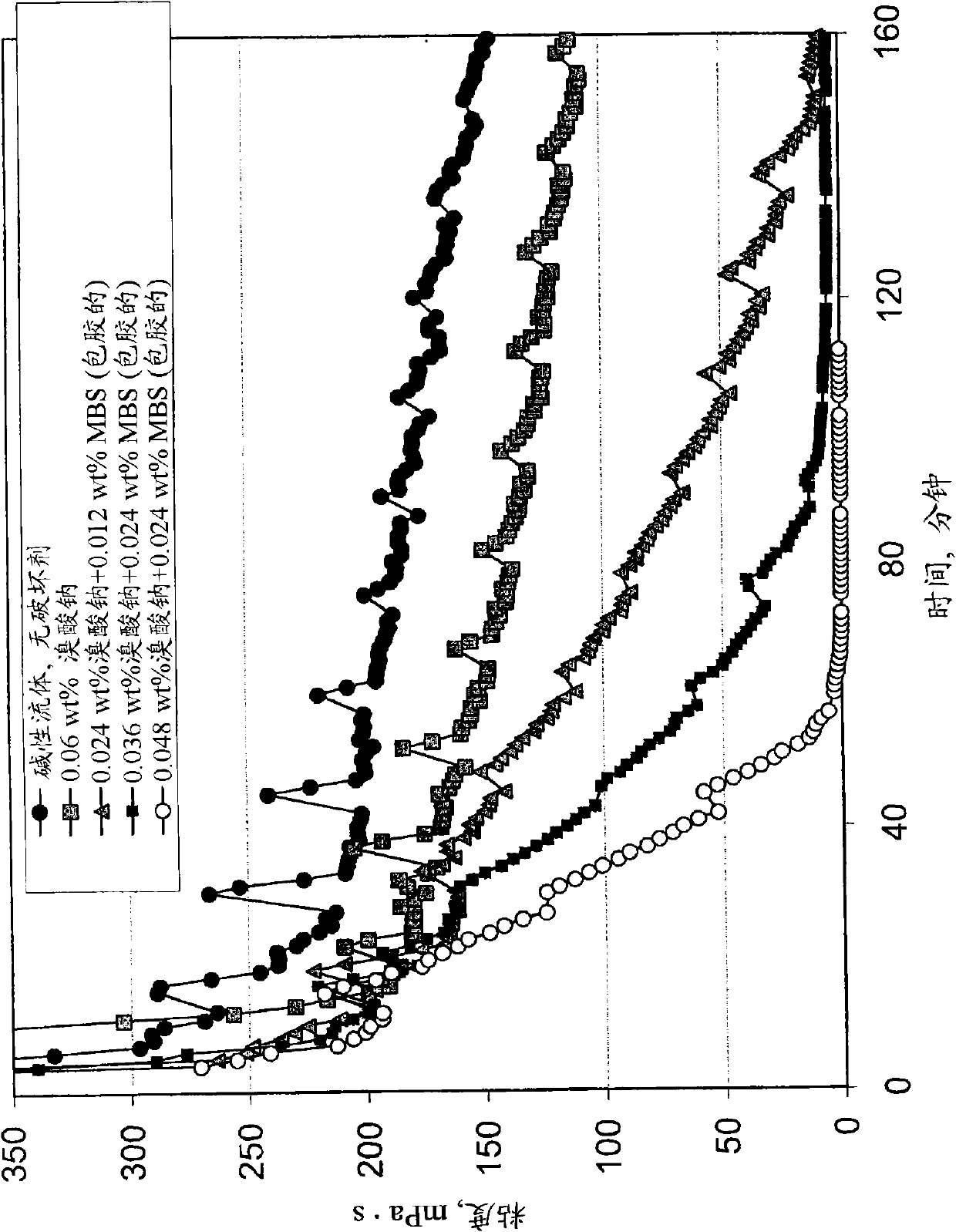

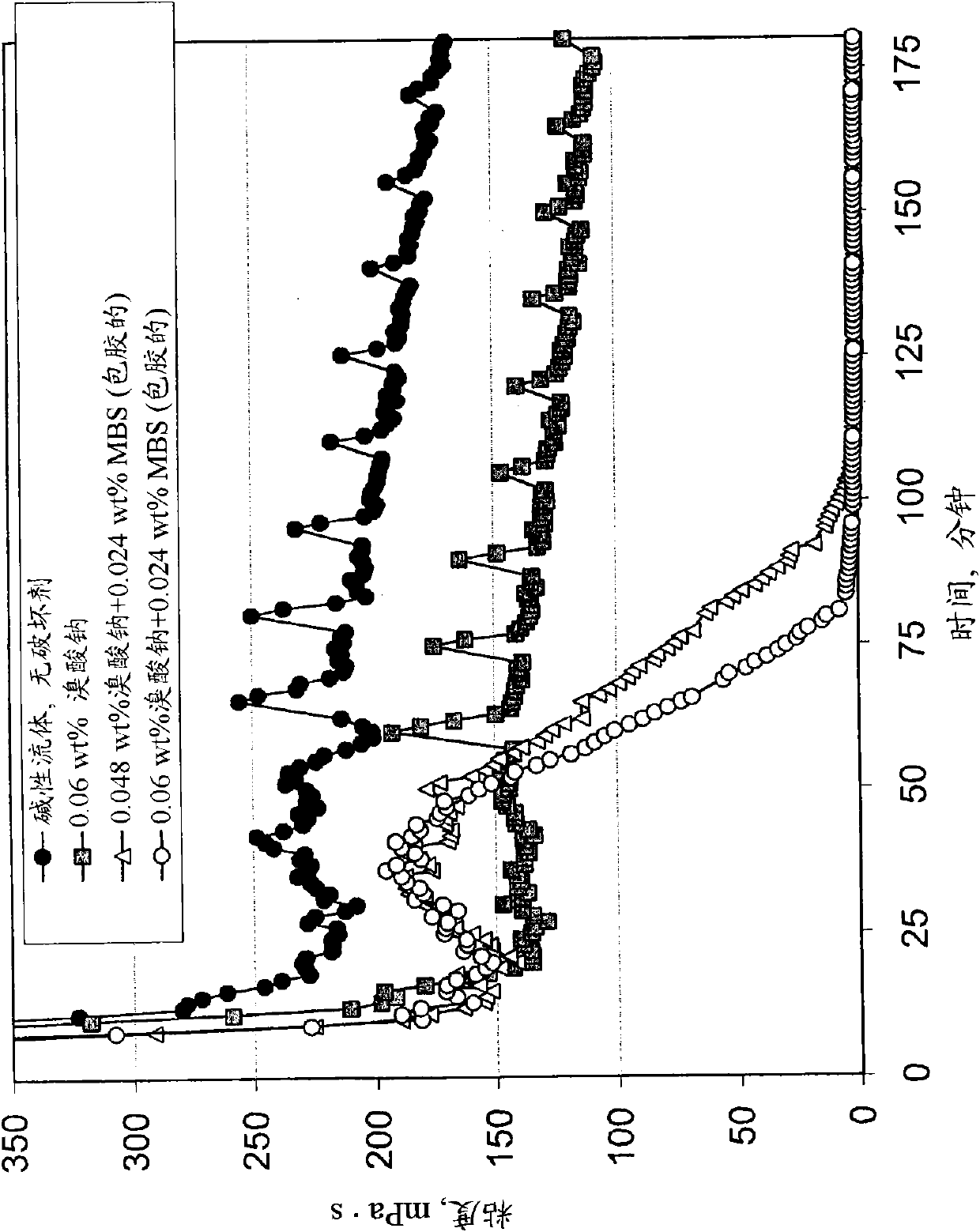

[0069] Encapsulated sodium metabisulfite particles containing 70% by weight of MBS coated with 30% by weight of polyvinylidene chloride were also tested as an activator for sodium bromate in order to obtain a delayed breakdown of the cross-linked fluid . The rheological data are shown in figure 2 , in which different concentrations and ratios of sodium bromate and encapsulated MBS were used. Delayed destruction was observed to be concentration dependent. The data are consistent with the corresponding oil bath test results. A drop in pH was noted when either bisulfite or MBS was used, but no drop was observed when the encapsulated form of MBS was used. In the case of borate fracturing fluids, the fluid loses viscosity when the pH decreases as borate crosslinkers convert to boron-containing species resulting in less active crosslinkers. The drop in pH can be compensated by adding a base such as sodium hydroxide to the fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com