Novel process for filtration of tail powder slurry of deep processed product of steel slag

A technology of deep processing and new process, applied in the new process field of filtration of tail powder slurry of steel slag deep processing products, can solve the problems of unfavorable transportation, poor filtering effect and high water content of products, achieve significant economic benefits, improve productivity, and recover secondary resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

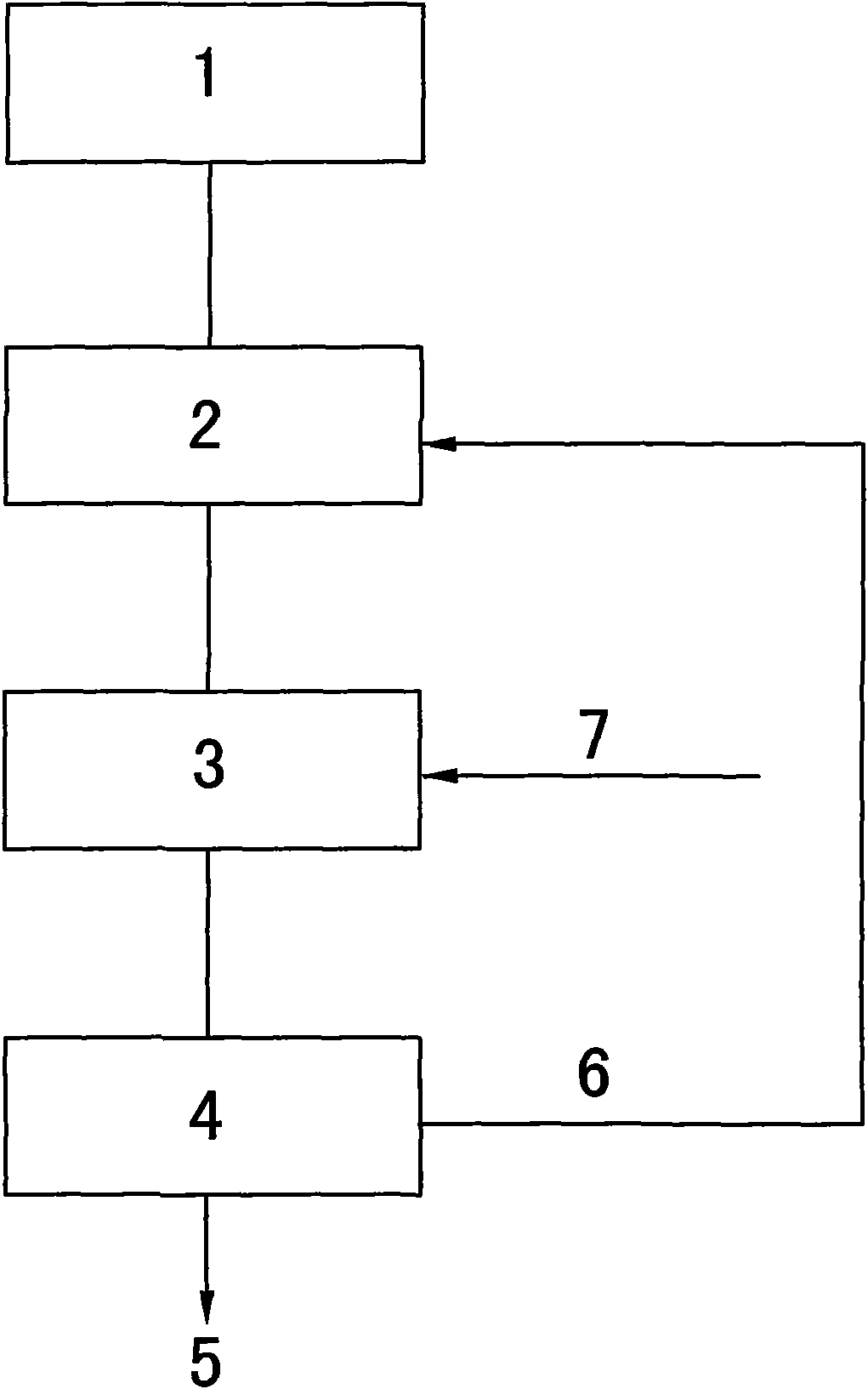

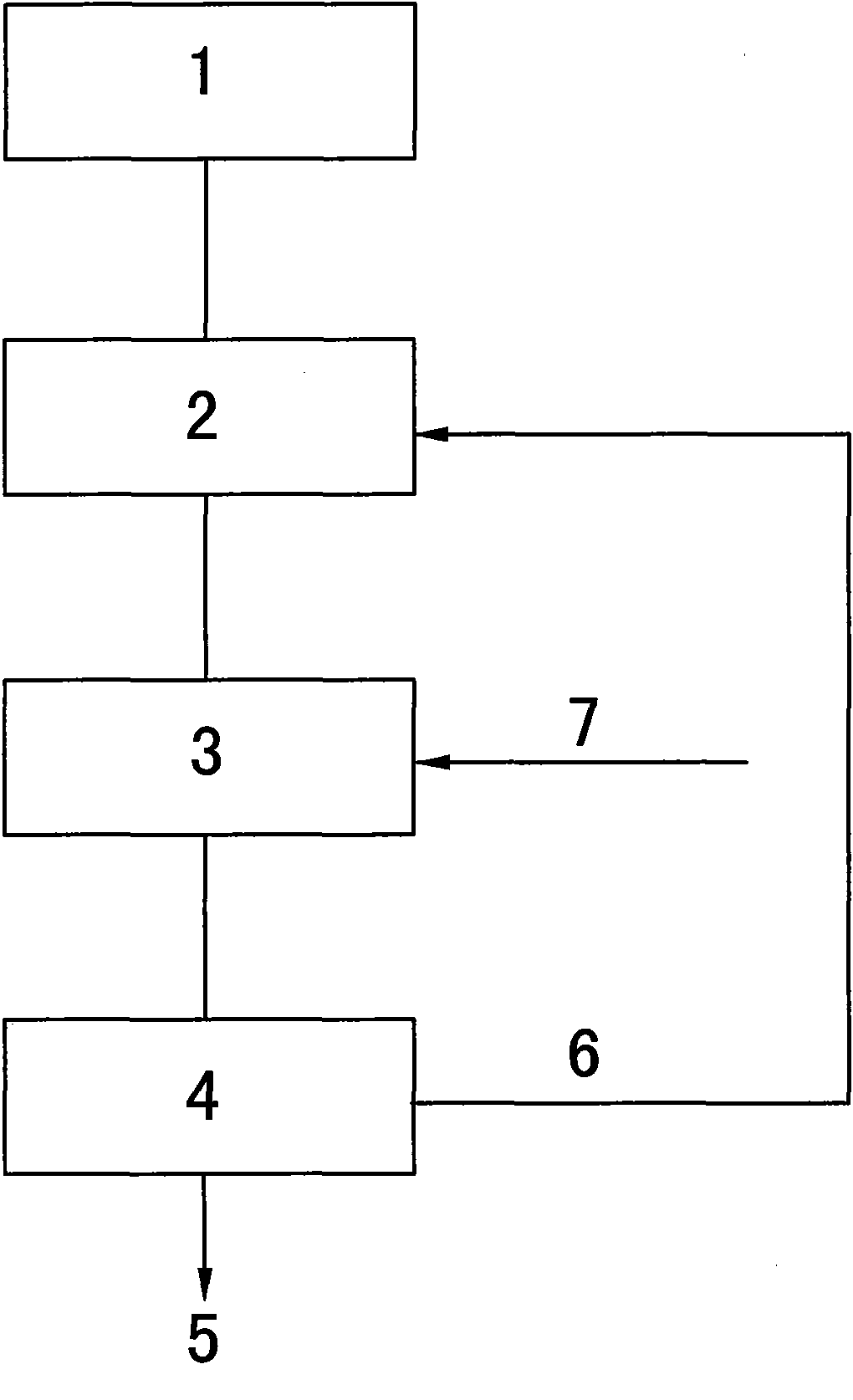

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 Shown, steel slag deep-processed product tail powder slurry filtration novel process of the present invention is characterized in that comprising the following steps:

[0019] 1) After the tailings slurry 1 after the deep processing of steel slag magnetic separation products is separated by the concentrator 2, the concentration of the slurry is 25-35%, and the slurry at the bottom of the concentrator 2 is pumped to the slurry at the top of the filter press 4 Adjust tank 3, the thickener is Concentrator

[0020] 2) At the same time, add polymer flocculant 7 into the slurry adjustment tank 3, the polymer flocculant is preferably polyacrylamide; the addition amount of the polymer flocculant is 0.45-0.55 kg / ton pulp;

[0021] 3) The concentrated pulp and polymer flocculant are fully mixed in the adjustment tank 3 and then flow into the filter press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap