Desulfuration waste water treatment process

A technology for desulfurization wastewater and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve high product purity, ensure product purity, and less processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

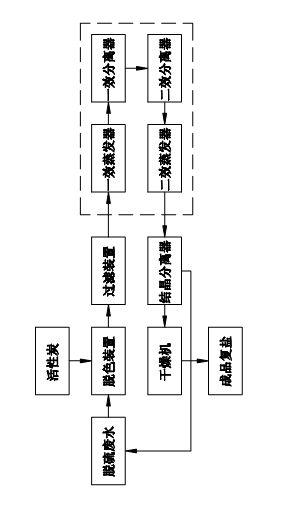

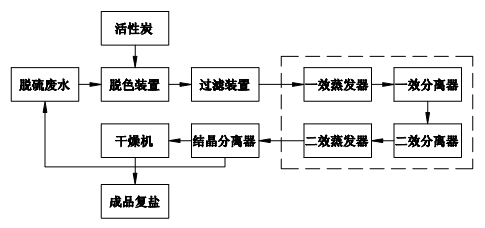

[0014] Such as figure 1 As shown, a treatment process for treating desulfurization wastewater in a coking plant mainly includes: a decolorization process, a filtration process, an evaporation separation process, a crystallization separation process and a drying process. The specific process steps are: first, introduce the waste water to be desulfurized into the decolorization device, and add activated carbon to the decolorization device for adsorption decolorization treatment. The amount of activated carbon added is based on activated carbon / waste water to be desulfurized = 5-10kg / m 3 The ratio is added, and the decolorization time is 4-6 hours. After filtering through the filter device, the colored substances and solid impurities in the wastewater to be desulfurized are removed by adsorption, and the visual inspection of no impurities and transparent color shall prevail. Then, the waste water after adsorption, decolorization and filtration is concentrated under negative press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com