Environmentally-friendly recycled polyethylene modified particles for emulsion explosive package and preparation method thereof

A polyethylene modified and emulsified explosive technology, which is applied in the field of polyethylene recycled materials, can solve the problems of limited direct application range, large drop in mechanical properties of recycled materials products, unsuitable for making high-grade products, etc., and is beneficial to environmental protection , The effect of improving the mechanical performance index and improving the degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

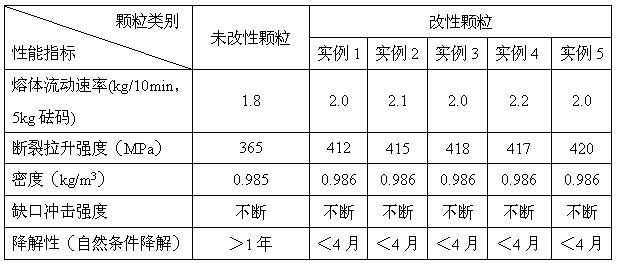

Examples

Embodiment 1

[0015] In the mixer, add 80kg of crushed, cleaned and dried waste toothpaste aluminum-plastic packaging recycled polyethylene plastic crushed materials, and then add 0.26kg of benzophenone, 0.028kg of iron octanoate, and 1.2kg of special toughening agent for PE, and mix evenly. mix. First control the temperature of the extruder at a certain temperature, add the mixed materials, melt and extrude through two layers of 80-mesh screens to pelletize. The obtained particles are modified particles.

[0016] During production, the process parameters are as follows:

[0017] Process temperature (°C) Zone 1 Zone 2 Zone 3 Zone 4 Head

[0018] 175±5 180±5 185±5 190±5 195±5

[0019] Melt pressure: melt pressure ≤ 7.0MPa

[0020] Host current: host current 60A, then appropriately reduce the feeding frequency or increase the temperature of the third zone, fourth zone or machine head accordingly,

[0021] Host frequency: 45±5Hz

Embodiment 2

[0025] In the mixer, add 80kg of crushed, washed and dried waste toothpaste aluminum-plastic packaging recycled polyethylene plastic crushed materials, and then add 0.26kg of chlorinated benzophenone, 0.028kg of zinc octanoate, and 1.2kg of PE special toughening agent. , mix evenly. First control the temperature of the extruder at a certain temperature, add the mixed materials, melt and extrude through two layers of 80-mesh screens to pelletize. The obtained particles are modified particles.

[0026] During production, the process parameters are as follows:

[0027] Process temperature (°C) Zone 1 Zone 2 Zone 3 Zone 4 Head

[0028] 175±5 180±5 185±5 190±5 195±5

[0029] Melt pressure: melt pressure ≤ 7.0MPa

[0030] Host current: host current 60A, then appropriately reduce the feeding frequency or increase the temperature of the third zone, fourth zone or machine head accordingly,

[0031] Host frequency: 45±5Hz

[0032] Cutting machine speed: between 300...

Embodiment 3

[0035] In the mixer, add 100kg of crushed, cleaned and dried waste toothpaste aluminum-plastic packaging recycled polyethylene plastic crushed materials, and then add 0.32kg of benzoin dimethyl ether, 0.033kg of cobalt octanoate, and 1.5kg of PE special toughening agent respectively, and evenly mix. First control the temperature of the extruder at a certain temperature, add the mixed materials, melt and extrude through two layers of 80-mesh screens to pelletize. The obtained particles are modified particles.

[0036] During production, the process parameters are as follows:

[0037] Process temperature (°C) Zone 1 Zone 2 Zone 3 Zone 4 Head

[0038] 175±5 180±5 185±5 190±5 195±5

[0039] Melt pressure: melt pressure ≤ 7.0MPa

[0040] Host current: host current 60A, then appropriately reduce the feeding frequency or increase the temperature of the third zone, fourth zone or machine head accordingly,

[0041] Host frequency: 45±5Hz

[0042] Cutting machine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com