Miniature high-sensitivity optical fiber chemical sensor

A chemical sensor and high-sensitivity technology, which is applied in the field of micro-high-sensitivity optical fiber chemical sensors, can solve the problems of inability to realize selective detection, and achieve the effect of simple structure, high sensitivity, and high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

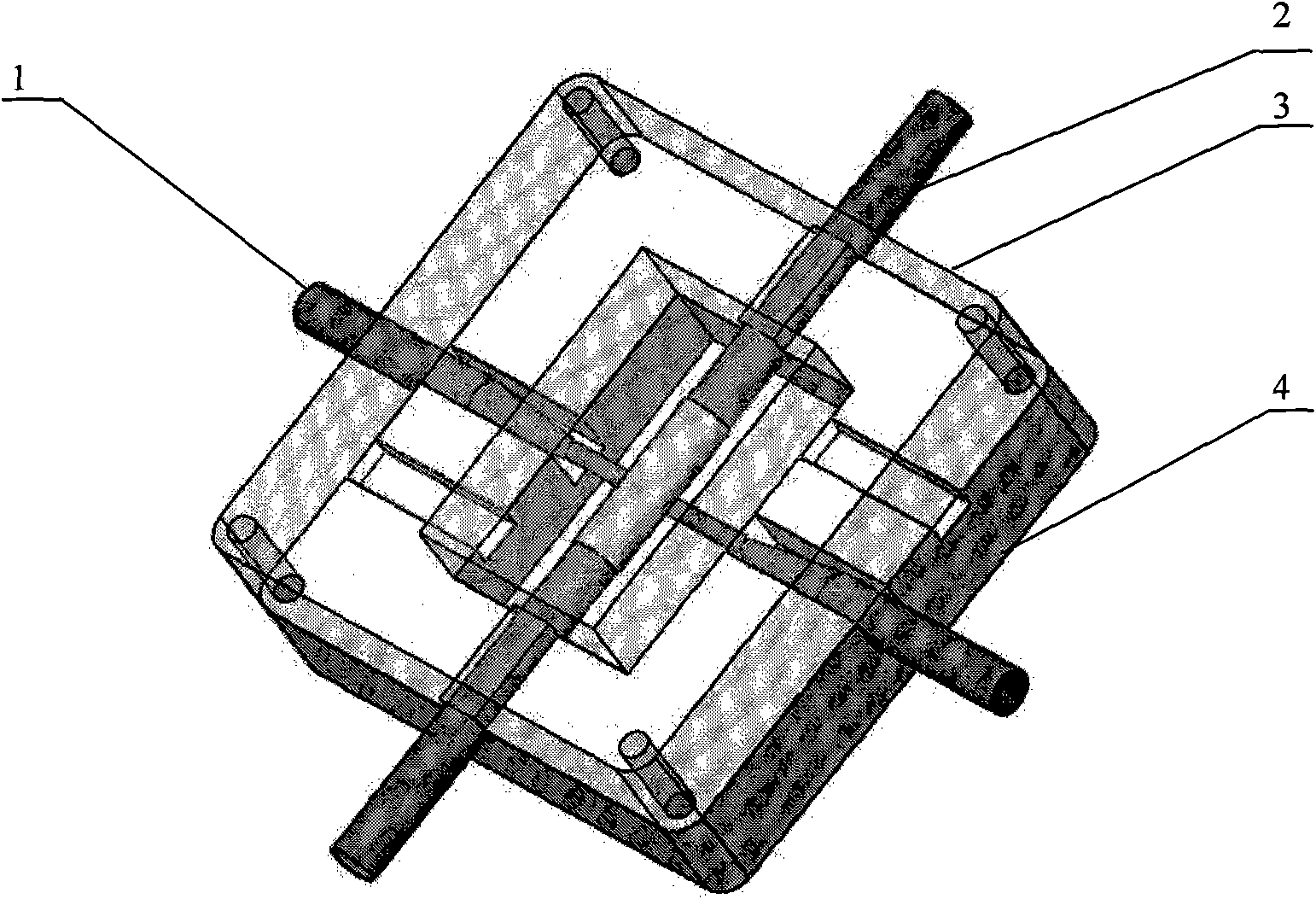

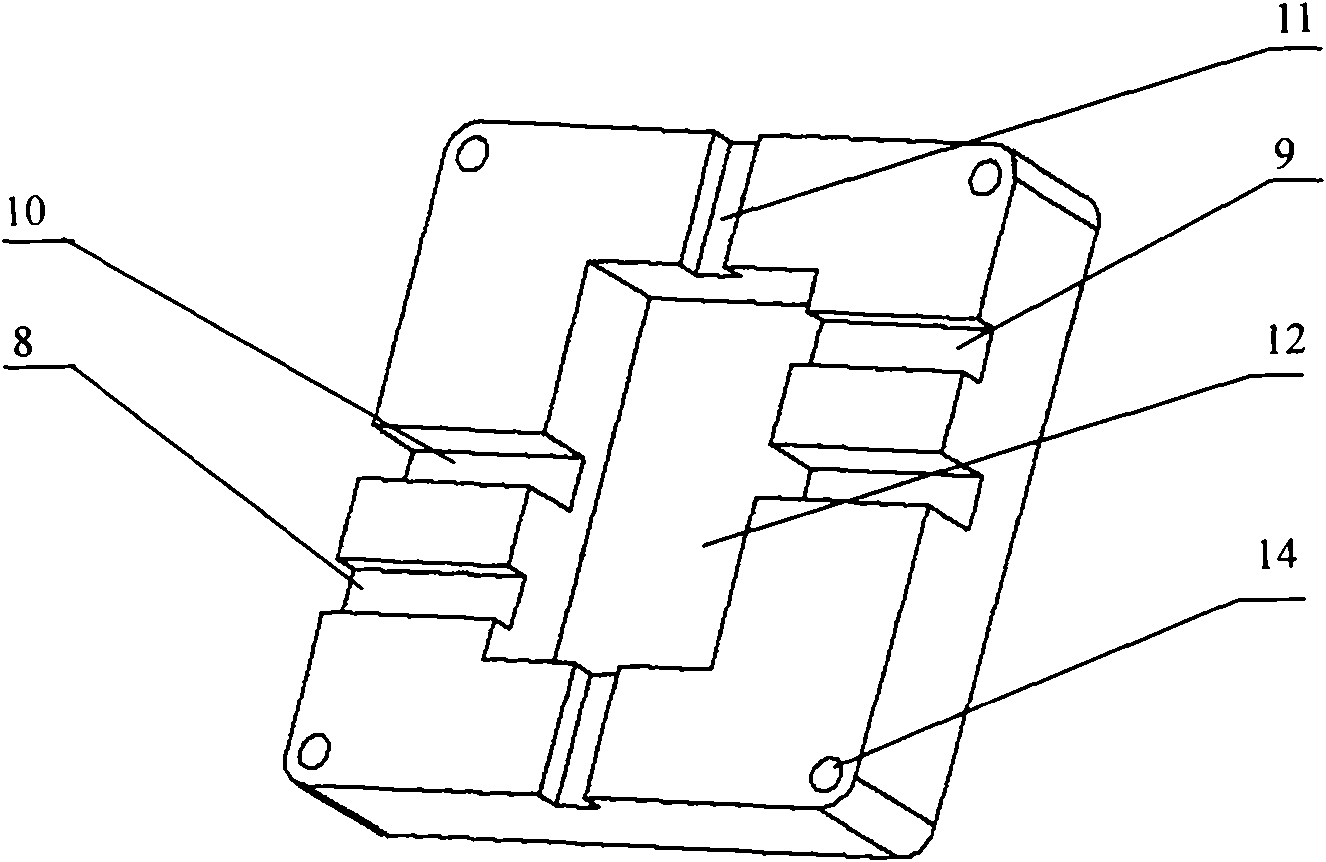

[0024] The overall structure of the optical fiber chemical sensor of the present embodiment is as follows figure 1 As shown, it includes a fiber cone 1 , a fiber resonator 2 , a top cover 3 and a base 4 .

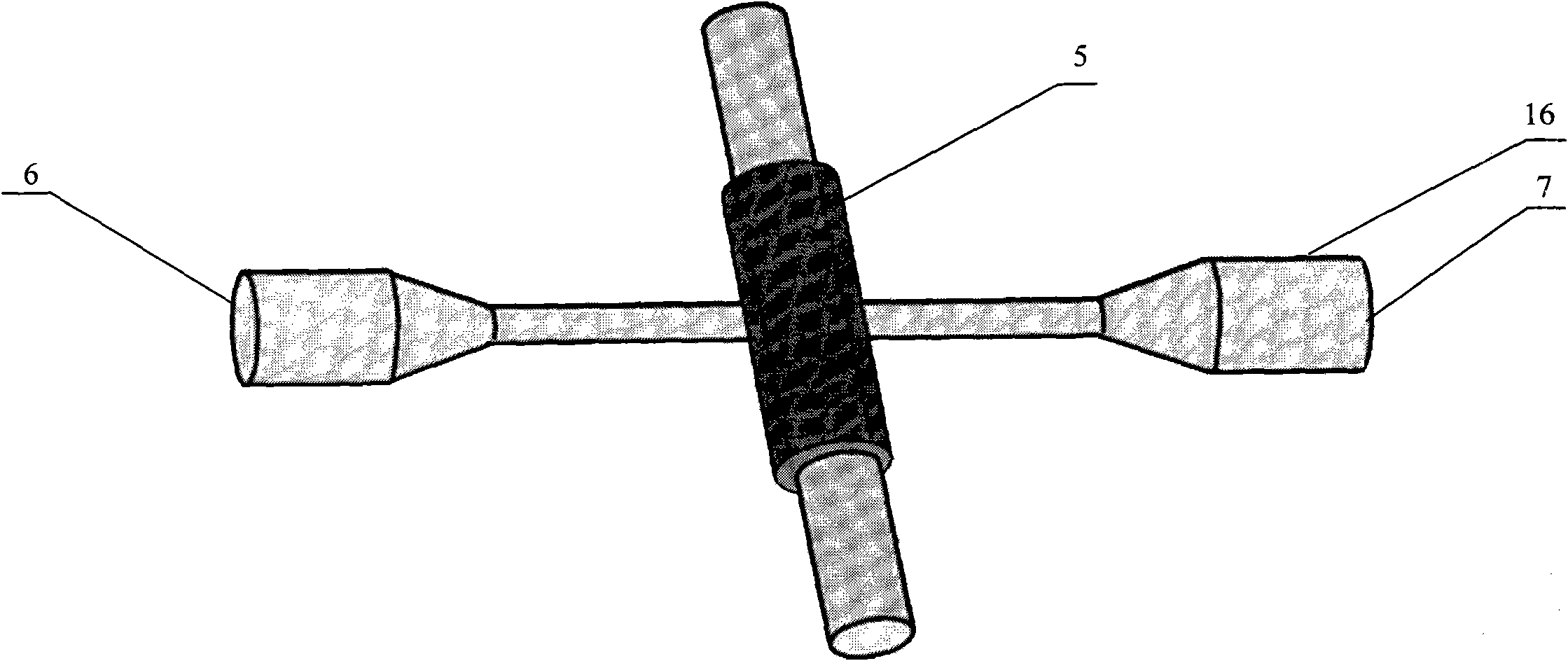

[0025] Among them, the fiber cone 1 and the fiber resonator 2 are made of Corning's single-mode fiber, such as figure 2 shown.

[0026] Preparation of optical fiber taper 1: Place the single-mode optical fiber in the tapering machine, start the tapering program after setting the parameters, the tapered optical fiber becomes a certain taper shape, and the diameter of the tapered waist is 1-2um.

[0027] The preparation of the optical fiber resonant cavity 2 coated with the zeolite film 5: take a single-mode optical fiber, remove the coating layer in the middle part w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com